There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

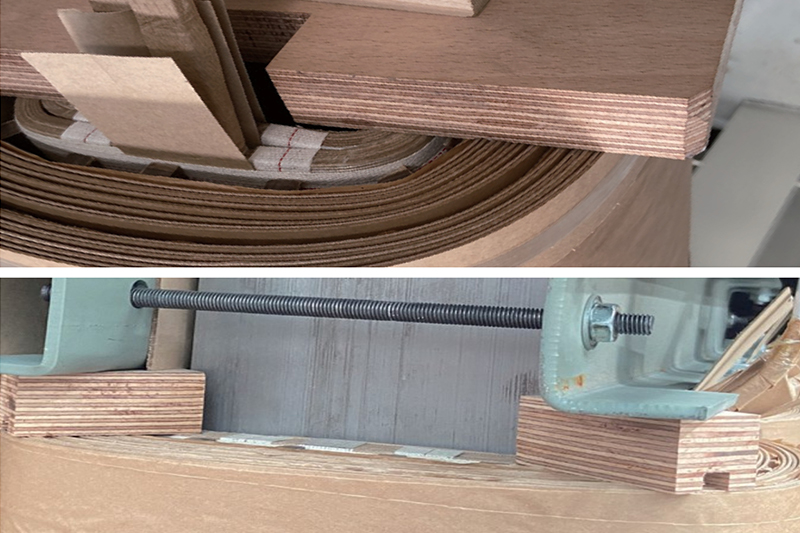

Electrical laminated wood is made from birch or beech,with excellent insulation, low moisture, high oil absorption, and metal-free safety, making it ideal for long-term transformer insulation and support components.

Email:ztelec@ztelecgroup.com Whatsapp:+8618695867837

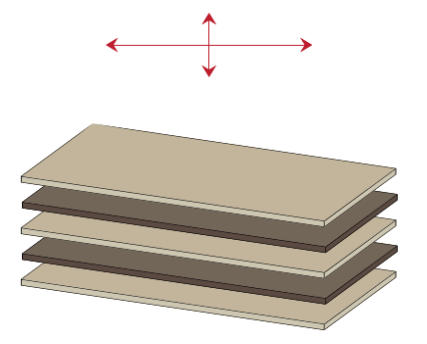

It is made of fine birch/beech wood by rotary cutting into thin woodveneers, which are then glued, laminated and hot-pressed.

Its dielectric constant is close to that of transformer oil, and it has good insulation properties, so it can be used in transformer oil forlong-term applications.

GBTT 20634.3-2008

IEC61061-1:1998

DIN7707

Class A

| Product name | XUJUE | LII/2-E3B/R | MII/2-E3B/R | LX/2-E3B/R | MX/2-E3B/R |

| GB/T20634 | C2B | C4B | T2B | T4B | |

| IEC61061 | C2R | C4R | T2R | T4R | |

| DIN7707 | KP20222 | KP20224 | KP20242 | KP20244 | |

| Unit |  |

|

|||

| SECTION I PHYSICAL CHARACTERISTICS | |||||

| Appearance | – | The surface… | |||

| Density | g/cm3 | 0.9-1.1 | 1.2-1.3 | 0.9-1.1 | 1.2-1.3 |

| Oil absorption | % | 25 | ≥5 | 25 | 7.5 |

| Continuous working temperature | °C | 105 | 105 | 105 | 105 |

| Temperature limit for drying process | °C | 140 | 140 | 140 | 140 |

| Contamination of dielectric liquids | Δtgδ | <0.1 | <0.1 | <0.1 | <0.1 |

| MECHANICAL CHARACTERISTICS | |||||

| Flexural strength | MPa | 110 | 130 | 130 | 200 |

| Modulus of elasticity in flexure | GPa | 9 | 11 | 11 | 15 |

| ELECTRICAL CHARACTERISTICS | |||||

| Electric strength | kV/3mm | 45 | 45 | 40 | 45 |

| Breakdown voltage | kV/25mm | >80 | >80 | >80 | >80 |

| Surface resistivity | Ω | 1012 | 1012 | 1012 | 1012 |

| Volume resistance | Ω*cm | 1012 | 1012 | 1012 | 1012 |

| Dissipation factor | tgδ | 0.01 | 0.01 | 0.01 | 0.01 |

| Relative permittivity | εr | 3.7 | 3.8 | 3.7 | 4.1 |

Note: All information,recommendations and suggestions appearing herein concerning this product are average values ascertained at room temperature by regular statistical analysis, it is provided purely for information and shall not be regarded as binding unless expressly agreed otherwise.

Great oil absorption property: It has rapid drying properties and maintains effective oil impregnation in air-free conditions. These characteristics contribute to reduced energy consumption while ensuring a high dielectric constant and eliminating partial discharge phenomena.

Low moisture content: The reduced moisture content decreases drying time during the steam stage, resulting insignificant energy savings and cost reduction. This moisture reduction minimizes the risk of corrosion in the transformer’s metallic working components.

Good electrical insulation properties: We have our own laboratories for performing mechanical and electrical testing.

100% metal detected: We ensure 100% test for all of our densified wood produced, thus avoiding potential danger caused by metal contaminants.

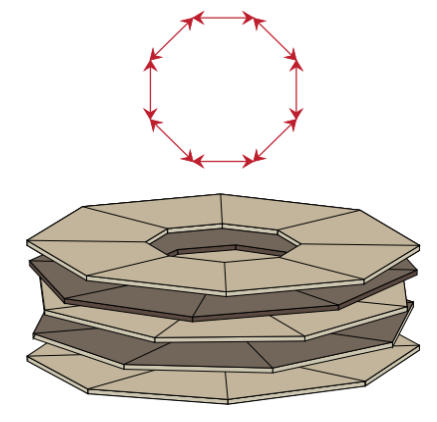

It is used to make insulation and support components in transformers, such as coil pressure plates, iron core backing plates, lead brackets, etc.

Store in a dry and clean room at room temperature, place it horizontally, pay attention to moisture-proof and fire-proof, and the storage period is 12 months.

If you need our products please write down any questions, we will reply as soon as possible.