There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……

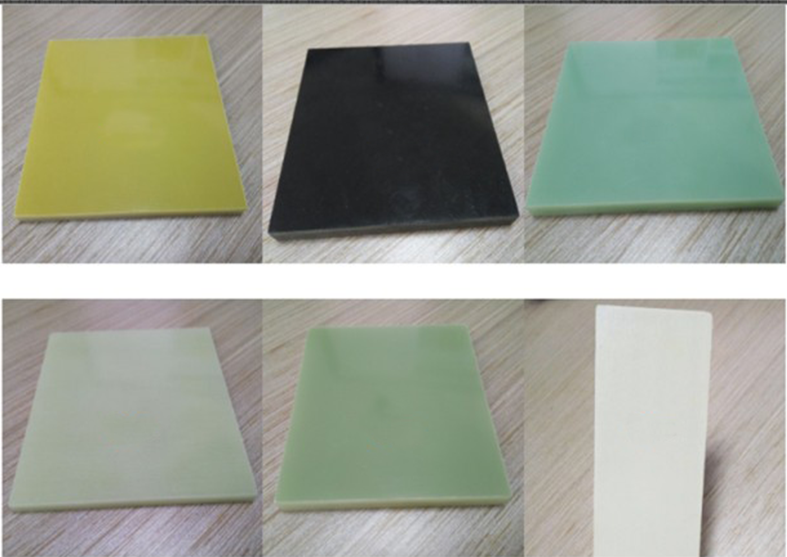

Color: Green/Water Green/White/Yellow/Black

Thickness: 0.1-100mm

Size:1020*1220 /1020*1020 /1220*2440 /1220*2040 (support customize)

Heat resistance rating: ClassB F H

Product introduction of FR4 G10 G11 Epoxy Board

FR4 G10 G11 are all epoxy glass fiber cloth laminates, which are laminated products made of chemically treated electrical alkali-free glass fiber cloth as the base material and epoxy resin as the binder. High mechanical strength and good electrical performance stability under high humidity.

FR-4 epoxy board: It is made by coating epoxy glass fiber cloth under high temperature and high pressure. It has high mechanical properties and stable electrical properties under high humidity. It is suitable for mechanical, electrical and electronic parts with high insulation structure. It has high mechanical and dielectric properties, good heat resistance and moisture resistance. Heat resistance class B

G10 glass fiber board: “G” in G10 represents glass fiber, 10 represents the content of glass fiber is 10%, G10 epoxy board is made by processing glass fiber cloth and epoxy resin. It has a certain mechanical strength without deformation, and has the characteristics of insulation, acid and alkali resistance. Good insulation strength, chemical resistance, radiation resistance and thermal shock resistance; good tensile strength, flexural strength and low temperature adaptability.

G11 laminated glass cloth board: G11 is similar to the G10 process, except that the glass fiber content is changed. Its main properties are the same, such as flame-retardant UL94-VO grade, good mechanical properties at high temperatures, and good processing and insulation properties. G11 epoxy board has stronger high temperature resistance and arc resistance

Video of Epoxy Laminated Glass Cloth Sheet

Yellow FR4 Green G11 Parameters

| Standard | GB/T 1303-2009 / IEC60893-2003 | ||||||||

| Basic Information | Chinese Name | epoxy fiber glass board | 3241 | ||||||

| IEC | EPGC201 | EPGC202 | EPGC203 | EPGC204 | EPGC306 | EPGC308 | – | ||

| NEMA | – | FR4 | G10 | FR5 | G11 | – | – | ||

| Basic Material | Glass fiber cloth | Electronic Grade Glass Fiber Cloth | Glass Fiber Cloth | ||||||

| Resin | Epoxy | Heat-resistant Epoxy Resin | Epoxy | ||||||

| Color | Natural | Green/Water Green/White/Yellow/Black | Black | ||||||

| No. | Test Item | Unit | Value | ||||||

| 1 | Density | g/m³ | 1.8~1.95 | 1.75~1.90 | |||||

| 2 | Vertical Layer Bending Strength (normal) | MPa | ≥340 | ≥300 | |||||

| 3 | Parallel Layer Impact Strength (simply supported beam method) | KJ/m2 | ≥38 | ≥50 | |||||

| 4 | Vertical Layer Electrical Strength(90℃transformer oil)(1mm thickness) | Kv/mm | ≥14.2 | ≥8.0 | |||||

| 5 | Parallel Layer Breakdown Voltage(90℃transformer oil) | kv | ≥35 | ≥35 | ≥40 | ≥35 | ≥40 | ≥35 | ≥35 |

| 6 | Dielectric Constant (50Hz) | – | ≤5.5 | ||||||

| 7 | Dielectric Loss Factor(50Hz) | – | ≤0.04 | ||||||

| 8 | Insulation Resistance after Immersion | Ω | ≥5.0*1010 | ≥1.0*108 | |||||

| 9 | Proof Tracking Index(PTI) | – | – | – | – | – | ≥200 | – | – |

| 10 | Combustibility | – | – | V-0 | – | V-0 | – | – | HB40 |

| 11 | Temperature Index | – | 130 | 155 | 155 | 155 | 155 | 180 | 155 |

| 12 | Water Absorption①(1-20mm thickness) | mg | 17~73 | 64-193 | |||||

| Note:①Range values are measured for different thicknesses | |||||||||

FR4 G10 Product Features

Epoxy glass fiber cloth board has higher mechanical properties, dimensional stability, impact resistance, and moisture resistance than paper substrates. The electrical insulation performance is stable, the flatness is good, the surface is smooth, no pits, and the thickness tolerance is standard. Its electrical performance is excellent, its working temperature is high, and its performance is less affected by the environment. In terms of processing technology, it is much superior to laminated glass fiber cloth boards made of other resins.

(1) Melting point of FR-4 process platen (203 ℃)

(2) High resistance to G10

(3) G11 low loss coefficient (Df 0.0025)

(4) Stable and low dielectric constant (Dk 2.35)

(5) Thermoplastic materials

Quality Assurance Of Fr4 G11 G10 Product:

1.No white cloth

2.No garbage cloth

3.No stitching

4.No sandwich panel

5.Environmental protection

6.Halogen-free

7.Good resin ensures stability

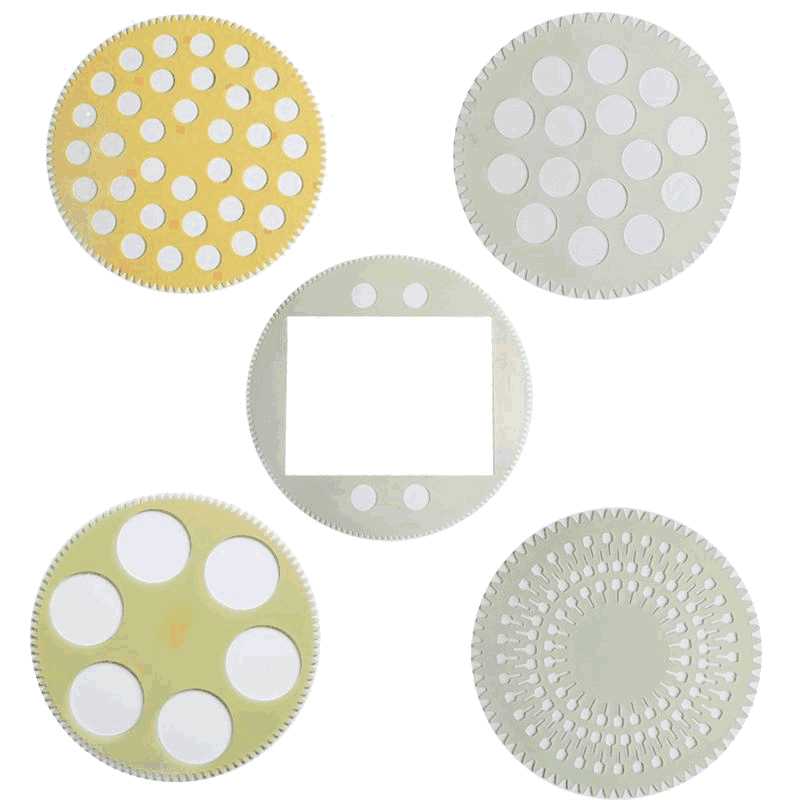

Electronic insulation FR4 Application

Epoxy glass fiber cloth board is suitable for products with high performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, carbon fiber printed glass fiber board, precision planetary gear (wafer grinding), precision test plate , Electrical (electrical) equipment insulation struts, insulation pads, transformer insulation plates, motor insulation, grinding gear, electronic switch insulation plates, etc.

Aqua green G10 board is generally used in computers, electronic switches, computer peripheral products, communication products, office automation equipment, automation instrumentation, military and avionics, household appliances and other products because it has good quality Stability and flatness, suitable for surface mount and package substrate requirements.

And yellow FR4 is widely used in digital display, dot matrix display, LED display, large screen display, electronic road signs, electronic sign board production, and electronic and electrical insulation structural parts with special requirements. Black substrates are widely used in optical instruments, cameras, and other products, which have the characteristics of stable quality and high flatness.

Color G10 Laminate Production Process

The production of g10 epoxy glass cloth laminates goes through 4 processes. The first step is to immerse the glass fiber cloth in epoxy resin. The second step is to cut into PP sheets after drying. The third part, finishing and superimposing to the corresponding thickness. The fourth step, hot press

Flame Retardant FR4 Board Warehouse Delivery

ZTELEC stores the produced FR4 epoxy board in the warehouse according to the thickness. Before shipping, it is necessary to wind the G10 glass fiber board with anti-collision film, label it, and put it in a carton.

G11 Glass Fiber Board Test Report:

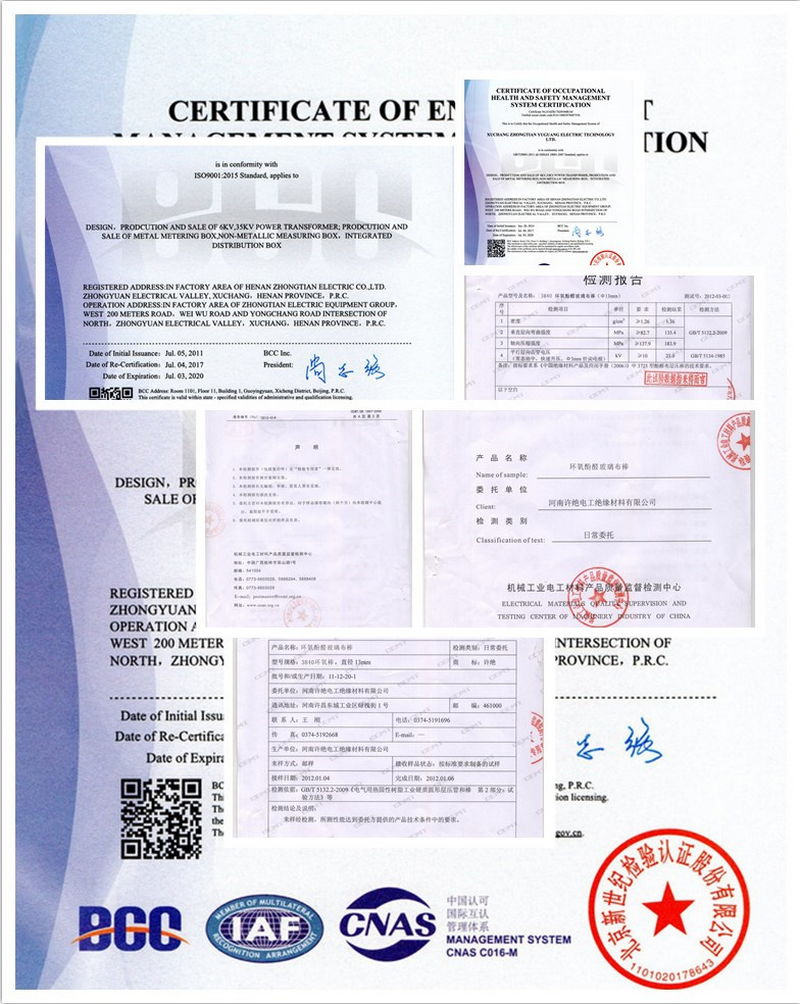

ZTELEC has three major certifications (ISO9001, ISO14001, OHSAS18001), and also has SGS certification and UL certification for G11 glass fiber board

Epoxy Board FAQ

1. Is ZTELEC a manufacturer?

ZTELEC is a Chinese manufacturer of insulating materials, established in 1958.

2. How long is your production cycle?

Regular size, less than 1T, delivery within 20 days

3. Do you support customization?

Products can be customized according to customer needs to support processed parts.

4. Is the sample free?

Our samples are free, but the customer needs to bear the shipping cost.

5. Is it in stock?

Our warehouse maintains inventory throughout the year, and some sizes can be shipped within a week.

If you need our products please write down any questions, we will reply as soon as possible.