In transformer manufacturing, the reliability of the insulation system directly determines the equipment’s operating efficiency, service life, and safety. As the power industry evolves toward higher voltage, larger capacity, and energy-saving technologies, traditional insulation materials are no longer able to meet the demands of complex operating conditions. DMD epoxy prepreg is a high-performance composite insulation material. Its excellent heat resistance, electrical properties, and process adaptability make it a core solution for transformer coil and winding insulation. This article will analyze how DMD epoxy prepreg is driving innovation in transformer insulation technology.

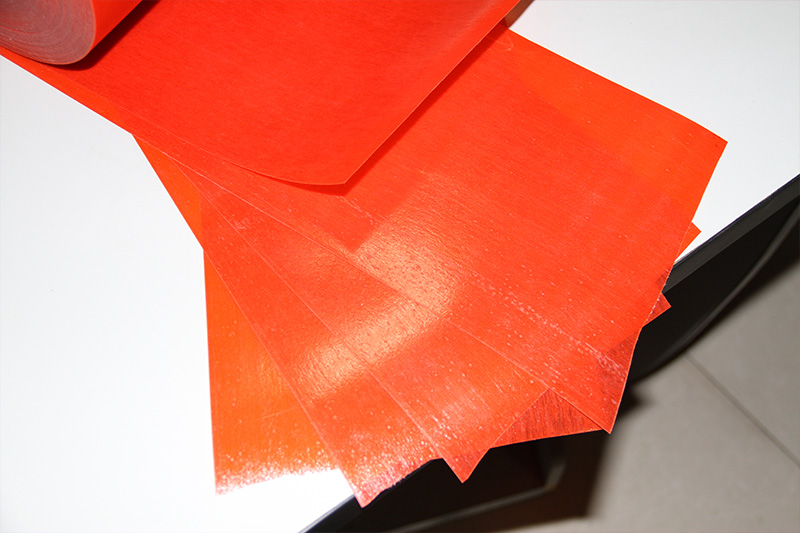

DMD epoxy prepreg is composed of a polyester film base, a polyester nonwoven reinforcement layer, and a modified epoxy resin through a pre-curing process. Its performance advantages stem from three core design features:

The addition of heat-resistant groups to the modified epoxy resin enables the material to achieve a temperature resistance rating of F (155°C), exceeding that of conventional polyester film (B-grade 130°C). Under high-temperature operating conditions, the resin’s molecular chain structure remains stable, preventing thermal decomposition and the resulting degradation of insulation performance, thereby extending the transformer’s service life.

After curing, the epoxy resin forms a dense cross-linked network, significantly increasing dielectric strength and effectively blocking high-voltage electric fields between coils. Furthermore, the material’s surface resistivity reaches as high as 10¹⁴Ω・cm, reducing partial discharge and corona phenomena, and lowering the risk of insulation failure.

The polyester non-woven reinforcement layer provides the material with high tear resistance and flexibility, adapting to bending, stretching, and other deformations required during transformer coil winding. The semi-cured material can be stored at room temperature, and the curing process can be combined with other steps such as transformer varnishing and drying, streamlining production.

DMD epoxy prepreg’s high dielectric strength prevents electrical breakdown between turns and layers, ensuring stable transformer operation under high voltage conditions. Its uniform insulation properties reduce partial discharge and enhance equipment reliability.

During operation, transformers are subject to electromagnetic forces, thermal expansion and contraction, and mechanical vibration. The high mechanical strength of DMD epoxy prepreg provides structural support for the coils, preventing deformation and displacement and ensuring a stable winding geometry.

Based on an epoxy resin system, DMD prepreg exhibits excellent thermal stability and can withstand the high temperatures generated during transformer operation (typically reaching 155°C or higher). It will not degrade over time, ensuring durable insulation performance.

DMD epoxy prepreg is compatible with most insulating varnishes and resin systems. During vacuum pressure impregnation (VPI), it fully penetrates the insulation, creating a void-free insulation system and improving insulation integrity.

This material has low moisture absorption, preventing moisture ingress and degrading insulation performance. Furthermore, it is resistant to transformer oil and most chemicals, ensuring long-term stable operation.

DMD epoxy prepreg is a key material for transformer coil and winding insulation. Its excellent electrical, mechanical, and thermal properties provide reliable protection for modern power transformers. For transformer manufacturers, power equipment engineers, and technical decision-makers, understanding and correctly using DMD epoxy prepreg is crucial to ensuring transformer product quality and performance.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……