Compared to conventional environments, electrical equipment operating in high-temperature conditions requires significantly higher standards for insulation materials. Insulation failure can shorten equipment lifespan or lead to safety accidents. G11 machined parts, with their high-temperature resistance, electrical insulation strength, and structural stability, have become a commonly used insulation material in high-temperature environments. This article analyzes the reasons for prioritizing G11 machined parts in high-temperature applications.

G11 material is a high-performance glass fiber reinforced epoxy resin laminate manufactured according to NEMA standards. It uses continuous glass fiber cloth as the substrate and high-temperature epoxy resin as the binder, cured under high temperature and pressure. This material possesses high mechanical strength, good electrical insulation, and reliable thermal stability.

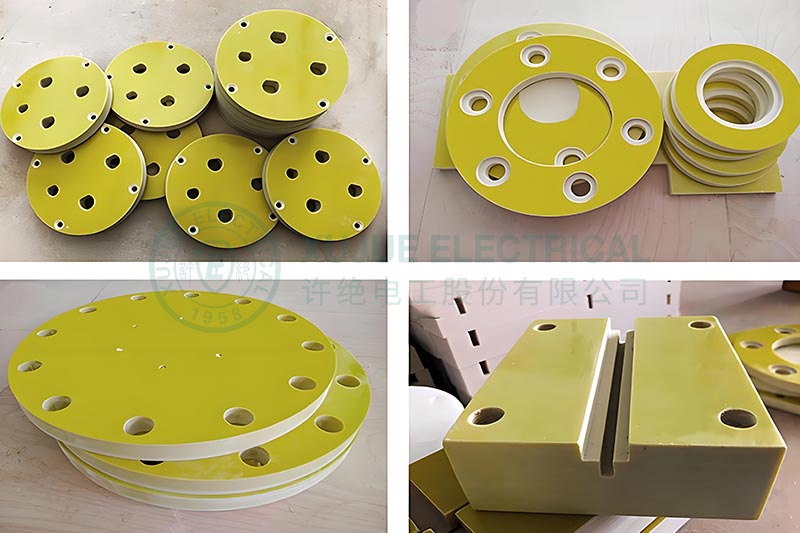

Through machining processes such as cutting, drilling, and milling, G11 sheets can be manufactured into various parts, collectively referred to as G11 machined parts. Currently, G11 machined parts are widely used in various fields such as insulation supports, structural components, gaskets, and slot wedges.

G11 material can be used continuously at 155°C for extended periods and can withstand even higher temperatures in short periods. Under high-temperature conditions, its shape remains stable and it is not easily softened or deformed.

Under high-temperature environments, the tensile strength, flexural strength, and compressive strength of G11 material decrease only slightly, allowing it to continuously withstand certain mechanical stresses and maintain structural integrity.

G11 machined parts maintain high dielectric strength and insulation resistance even in high-temperature or high-humidity environments. It is suitable for insulating components in high-temperature electrical equipment, contributing to safe equipment operation.

G11 material has low moisture absorption and stable performance in humid and hot environments. It also exhibits resistance to most oils, solvents, and weak acids and alkalis, making it suitable for various media environments.

G11 machined parts meet the UL94 V-0 flame retardant rating and are not easily combustible. During high-temperature decomposition, its smoke density is low and its toxicity is low, which helps improve equipment operational safety.

G11 machined parts are suitable for various high-temperature, high-load electrical equipment, such as:

Dry-type transformers and cast-resin transformers

High-temperature motor insulation structural components

Medium and high-voltage switchgear insulation support components

New energy inverter systems

Metallurgical, mining, and electric furnace equipment

These applications require high heat resistance, insulation, and reliability of materials, making G11 machined parts a common choice.

They offer superior long-term temperature resistance, stable electrical insulation at high temperatures, and are less prone to mechanical deformation. They are also easy to customize. These characteristics make them reliable in high-temperature environments, have a long service life, and offer a cost advantage.

Confirm Operating Temperature: Confirm that the long-term operating temperature is below 155°C.

Determine Load Type: Clarify the mechanical stress, vibration intensity, and electrical load that the G11 machining part needs to withstand.

Consider Environmental Media: Understand the chemicals and humidity factors that the machining part will come into contact with.

Clarify Precision Requirements: G11 material can be precision machined, but the dimensions and tolerances of the components must be determined in advance.

Confirm Certification Requirements: If the equipment needs to comply with UL, RoHS, or other certification standards, G11 sheet material that meets the corresponding standards should be selected.

In the selection of materials for high-temperature operating conditions, G11 machining parts, with their high temperature resistance, high insulation performance, and stable mechanical strength, have become a common choice in the field of electrical equipment. It provides a reliable and economical solution for the insulation and structural support of electrical equipment in high-temperature environments.

For information on G11 machining parts suitable for high-temperature operating conditions, please contact us.

We will provide detailed technical parameters, processing solutions, and quotations based on your specific application environment, size requirements, and temperature resistance rating.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……