In the power equipment and high-end motor manufacturing industry, the performance of insulation materials directly affects product reliability, operating efficiency, and service life. With increasingly stringent product design standards and shorter project delivery cycles, obtaining insulation materials that meet specific technical specifications while ensuring rapid delivery has become a key concern for engineers and procurement teams.

To address this need, we focus on providing high-performance AHA insulation composite paper, and we can become your reliable supply chain partner. We not only ensure excellent and stable material quality but also leverage a flexible customized production system and efficient fast delivery services to fully support the smooth implementation of your projects.

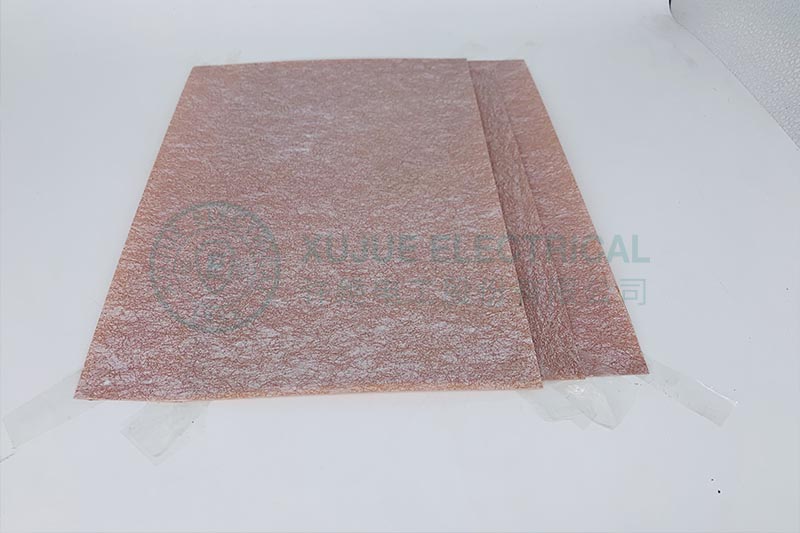

AHA insulation composite paper typically employs a three-layer composite structure of aramid paper, high-performance film, and aramid paper. It combines the high-temperature resistance of aramid materials with the mechanical strength of composite materials. It is suitable for mid-to-high-end electrical insulation applications.

Excellent high-temperature resistance, with a long-term operating temperature up to 180℃

High dielectric strength and stable insulation performance

Tear resistance, bending resistance, and high mechanical strength

Good chemical corrosion resistance and aging resistance

AHA insulating composite paper can be used in a variety of electrical equipment:

Oil-immersed/dry-type transformers: Used for interlayer insulation of coils, lead insulation, etc.

High and low voltage motors and generators: Used as slot insulation, phase-to-phase insulation, and padding insulation material.

Reactors and transformers: Used for main insulation and local reinforcement insulation.

New energy field: Suitable for photovoltaic inverters, wind power generation equipment, electric vehicle drive motors, etc.

This material is particularly suitable for electrical systems with high requirements for heat resistance and long-term stability.

AHA insulating composite paper is produced using high-quality aramid fiber and other raw materials. This ensures that it has high tear strength, high dielectric strength, and stable chemical and thermal properties, conforming to international standards such as IEC and NEMA.

We understand the specific needs of different application scenarios and can provide customized solutions based on customer technical parameters, including:

Thickness and Weight: We offer standard products in multiple specifications and also support customization of specific parameters.

Size and Slitting: We can provide rolls and sheets as needed and slit them to the required width and length.

Performance Enhancement: We can laminate or coat other functional materials as needed to improve properties such as voltage resistance, thermal conductivity, or flame retardancy.

We value the impact of project cycles on our clients and have established an efficient supply chain and production management system:

Rapid Delivery of Standard Specifications:

For commonly used specifications, we maintain safety stock, shortening order turnaround time and ensuring our clients’ R&D and production progress.

Efficient Response to Customized Orders:

Even with customized needs, we streamline processes to shorten delivery cycles. Orders are tracked by dedicated personnel from confirmation to shipment, ensuring transparency and efficient execution.

Logistics Support:

We partner with multiple international logistics providers, offering various transportation options to ensure safe and timely product delivery.

All AHA insulating composite paper undergoes multiple rigorous tests, including:

Thickness tolerance and appearance inspection

Dielectric strength testing

Heat aging resistance testing

Mechanical strength testing

We can also provide corresponding test reports and technical data support according to client needs.

AHA insulating composite paper, with its superior performance, has become a commonly used material in the high-end electrical insulation field. Choosing a supplier with the ability to deliver quickly and provide customized services helps improve project efficiency and product market competitiveness.

Contact us for a personalized quote and professional technical consultation!

Whether you need small sample tests or large-volume orders, we will provide you with insulation material solutions that meet your needs through professional service, reliable quality, and rapid response.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……