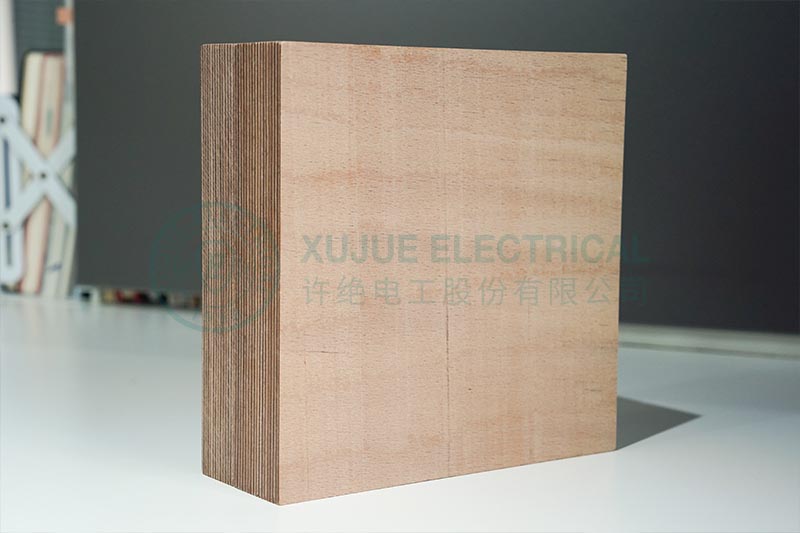

In the manufacturing and operation of power transformers, the performance of insulation materials directly affects the safety, operational stability, and service life of the equipment. Electrical laminated wood, as a key insulation and structural material in transformers, has become a widely used high-performance insulation material in the power transformer field due to its high mechanical strength, excellent electrical insulation properties, and ease of processing.

Electrical laminated birch wood has been used in power transformers for decades, and its performance has been verified through long-term practical operation. Compared to other materials, electrical laminated birch wood achieves a good balance between performance and cost:

It meets both electrical and mechanical operational requirements while maintaining a reasonable cost.

At the same time, it retains the ease of processing of natural wood while achieving stable performance through modern processes.

For transformer manufacturers and power companies, using qualified electrical laminated wood can bring the following benefits:

Reduced transformer failure risk

Extended equipment lifespan

Reduced maintenance frequency and costs

Improved grid reliability

Electrical laminated birch wood features high dielectric strength and low dielectric loss, enabling it to withstand the electric field intensity during transformer operation and ensure long-term insulation reliability.

High mechanical strength, suitable for use as winding support components.

Low moisture absorption, with minimal influence from humidity.

Good deformation resistance, maintaining dimensional stability under temperature changes and mechanical stress.

The thermal class is typically Class B (130°C) or Class F (155°C).

Low coefficient of thermal expansion, resulting in minimal dimensional changes under temperature variations.

Resin-impregnated structure improves moisture resistance.

Resistant to transformer oil and common chemical substances.

Some products comply with the UL94 V-0 flame-retardant standard.

Winding supports and spacers

Lead fixing and insulation components

Core clamping parts and spacer blocks

Various insulating connectors and structural components

Electrical laminated wood is suitable for a wide range of power transformers and electrical equipment, including:

Oil-immersed power transformers

Distribution transformers

Instrument transformers and reactors

Special industrial transformers

Electrical equipment for new energy and rail transit systems

Whether for medium- and low-voltage or high-voltage transformer systems, electrical laminated wood provides reliable insulation and structural support.

Material Standards: Complies with international standards such as IEC 60641 and IEEE Std C57.12.00

Thickness Range: Standard 10-100 mm, customization supported

Pretreatment: Strictly control moisture content

Surface Treatment: Smooth, rough, or grooved surfaces available upon request

Raw Material and Finished Product Uniformity Testing

Dielectric Strength Testing

Dimensional Tolerance Control (Standard ±0.2 mm)

Surface Smoothness and Finish Inspection

Resin Impregnation Saturation Verification

♦ Premium Raw Materials

♦ Strict Impregnation and Pressing Processes

♦ Guaranteed Quality Control

♦ High Dimensional Accuracy and Good Batch Consistency

♦ Suitable for Long-Term Oil Immersion Environments

♦ Supports Bulk Supply and Custom Production

♦ Product Quality Meets Export Standards

We not only provide high-quality electrical laminate insulation materials but also complete transformer insulation solutions, supporting the stable operation of transformers.

For electrical laminate insulation materials specifically designed for power transformers, we are committed to improving the safety and reliability of your products through stable product quality, professional technical support, and an efficient service system.

Please contact us for samples, technical data, and quotations.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……