In practical applications of electrical equipment, industrial automation, new energy, and high-temperature conditions, the safety and service life of equipment directly depend on the performance stability and processing precision of the insulation materials.

As commonly used categories of glass fiber reinforced epoxy resin insulation materials, G10, G11, and FR4 processing parts are widely used in transformers, motors, switchgear, and power electronic equipment due to their electrical properties, mechanical strength, and high-temperature resistance.

This article will explain the material characteristics, performance differences, typical applications, and key points of customized processing for G10/G11/FR4 machined parts to help users select the right materials.

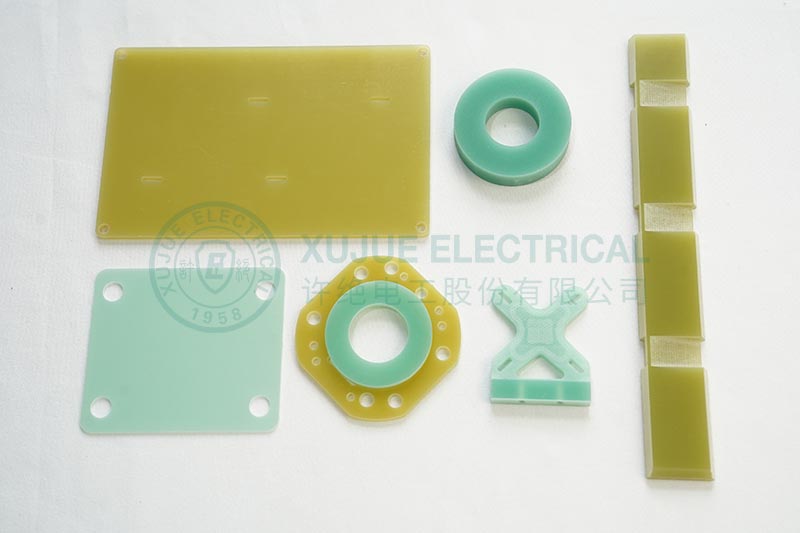

G10, G11, and FR4 all belong to glass fiber reinforced epoxy resin laminates. After processing such as CNC machining, drilling, milling, and waterjet cutting, they can be made into insulating structural and functional parts such as supports, partitions, insulating pads, and insulating flanges.

G10 machined parts: Possessing mechanical strength and electrical insulation properties, suitable for conventional industrial and electrical applications.

G11 machined parts: Improved heat resistance compared to G10, suitable for long-term high-temperature operation.

FR4 machined parts: Flame-retardant (compliant with UL94 V-0 standard), suitable for electronic, electrical, and other applications with high safety requirements.

| Property | FR4 | G10 | G11 |

| Continuous Operating Temperature | 130 °C | 130 °C | 155 °C |

| Flame Retardant Rating | UL94 V-0 | Non-flame retardant | UL94 V-0 (most grades) |

| Typical Applications | PCBs, electrical insulation | Mechanical structural parts, insulation supports | Electrical equipment in high-temperature environments |

Winding Supports

End Plates

Phase Spacers

G11 machining parts maintain dimensional stability under high temperature and strong electric field conditions, making them a commonly used insulation material in dry-type transformers.

Insulating Pads

Structural Supports

Positioning Insulation Parts

G10 and G11 machining parts possess vibration resistance and mechanical strength, making them suitable for motors and power generation equipment.

Insulating Brackets

Circuit Breaker Insulation Components

Busbar Supports

FR4 machining parts, due to their flame-retardant properties, are widely used in power distribution systems.

Photovoltaic Inverter Insulation Parts

Energy Storage System Structural Insulation Parts

Internal Insulation Components for UPS and Frequency Converters

Machining of G10, G11, and FR4 materials requires specialized equipment and techniques. Specific processes include:

G10, G11, and FR4 materials can be precision-machined using CNC milling machines, drilling machines, and lathes to produce dimensionally accurate parts. Carbide cutting tools are used during machining of these materials, and feed rate and cooling must be controlled to reduce tool wear and material delamination.

This machining method is suitable for cutting complex shapes, has no heat-affected zone, and maintains the integrity of material edges.

This machining method is suitable for high-precision cutting of thinner sheets, but slight carbonization may occur at the cut edges.

Drilling and tapping can be performed on all three materials, but the brittleness of epoxy resin must be considered, and appropriate drill angles and cutting parameters must be selected.

This includes sandblasting, chamfering, and polishing, which can be selected according to actual needs.

Certification Requirements: Clarify whether the product needs to comply with UL, RoHS, REACH, and other certification standards.

Tolerance Control: Clarify machining accuracy requirements, especially for components used in precision assembly.

Bulk Quantity and Cost: Plan procurement batches reasonably based on the cost differences between small-batch prototype production and large-scale mass production.

Supplier Evaluation: Evaluate the supplier’s processing capabilities, quality control level, and industry experience.

Sample Testing: Conduct performance testing on samples before bulk procurement to ensure they meet application requirements.

G10, G11, and FR4 machined parts provide high-temperature insulation solutions for various industries. Understanding the characteristics and differences of these materials, combined with actual application needs, helps in making appropriate material selections. Whether it’s electronic circuit boards, high-temperature electrical equipment, or precision mechanical components, selecting suitable insulation materials plays a crucial role in ensuring equipment performance, safety, and operational reliability.

Contact us for technical advice, material selection support, and customized quotation services.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……