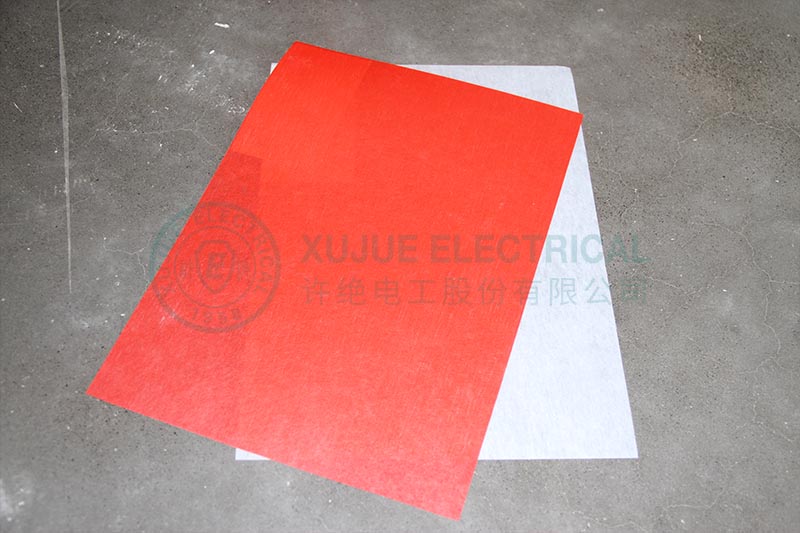

DMD insulation materials are commonly used for interlayer, slot-to-slot, and phase-to-phase insulation in electrical equipment such as motors and transformers due to their excellent electrical properties and mechanical strength. Depending on the application requirements, red prepreg DMD and white DMD have become common choices. This article analyzes these two materials from three aspects: thickness specifications, density differences, and insulation grades, providing selection references for engineers and purchasing personnel.

DMD is a three-layer insulation material composed of a polyester film and two layers of non-woven cloth. It possesses electrical insulation and mechanical flexibility, and is mainly used in the following applications:

Interlayer insulation of transformer windings

Slot insulation of motors

Phase-to-phase insulation of electrical equipment

Red prepreg DMD is a material made by pre-impregnating ordinary DMD with heat-resistant resin.

Main Features:

Red Appearance: Easy to identify

Uniform Resin Distribution and Good Heat Resistance

More Stable Structure After Hot Pressing

Suitable for Mid-to-High-End Transformers and Motors

White DMD is standard DMD material that is unpre-impregnated or only lightly treated.

Main Features:

Lower Cost

Good Flexibility and Easy Processing

Suitable for General Insulation Applications

Mostly Used in Ordinary Motors and Low-Voltage Transformers

Thickness affects the electrical strength, space occupied, and flexibility of insulation materials. Common units are millimeters (mm) or micrometers (μm).

Common Thickness Ranges:

♦ White DMD: 0.15mm, 0.20mm, 0.25mm, 0.30mm, etc.

♦ Red Prepreg DMD: 0.1mm, 0.12mm, 0.15mm, etc.

Red prepreg DMD may have a slightly higher actual thickness for the same nominal thickness due to the resin content.

Selection Recommendations:

♦ Low-voltage small motors: Generally, 0.15-0.20mm white DMD material is selected.

♦ Medium-high voltage motors: It is recommended to use 0.20-0.30mm or thicker material. If VPI technology is used, select red prepreg DMD of the corresponding thickness.

The density of DMD material is related to its structural compactness and mechanical strength.

White DMD has a lower density and better flexibility. Red prepreg DMD has a slightly higher density and a more compact structure. Higher-density DMD materials typically have the following characteristics:

Better voltage resistance

Stronger compressive and tear resistance

Better thermal aging stability

| DMD Type | Insulation Class | Maximum Continuous Operating Temperature |

| White DMD | Class B | 130 °C |

| Red Prepreg DMD | Class F (typical) | 155 °C |

For equipment operating at higher temperatures or under significant load fluctuations, red prepreg DMD is recommended as the preferred choice.

For VPI, molding, or roll-impregnation processes that require integral coil forming, choose red prepreg DMD.

For conventional wrapping or insertion insulation methods without overall impregnation, white DMD is suitable.

Select the thickness and dielectric strength (kV/mm) of the insulation material based on the equipment’s operating voltage.

Thicker materials are recommended for high-voltage applications.

The long-term operating temperature determines the required insulation class (e.g., Class B or Class F).

In humid environments, chemically corrosive conditions, or applications with high vibration, red prepreg DMD with curable sealing properties is recommended.

For areas with higher mechanical strength, abrasion resistance, or tensile requirements, select DMD materials with higher density and greater thickness.

Red prepreg DMD and white DMD each have distinct advantages in terms of structure, density, and insulation class. Selecting the appropriate thickness and thermal rating based on actual application requirements ensures electrical safety and helps extend equipment service life.

If you are looking for red prepreg DMD or white DMD materials, please feel free to contact us for detailed specifications, samples, and professional selection support.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……