Fiberglass tubes are widely used in various industries such as power, chemical, machinery manufacturing, and new energy due to their excellent insulation properties, corrosion resistance, and light weight. However, many users face the following questions during the actual procurement process: What are the differences between ordinary fiberglass tube and filament wound fiberglass tubing? How should one choose?

This article will systematically explain the core differences between the two from the aspects of product overview, performance differences, application scenarios, and selection suggestions, helping you choose the material that best suits your needs.

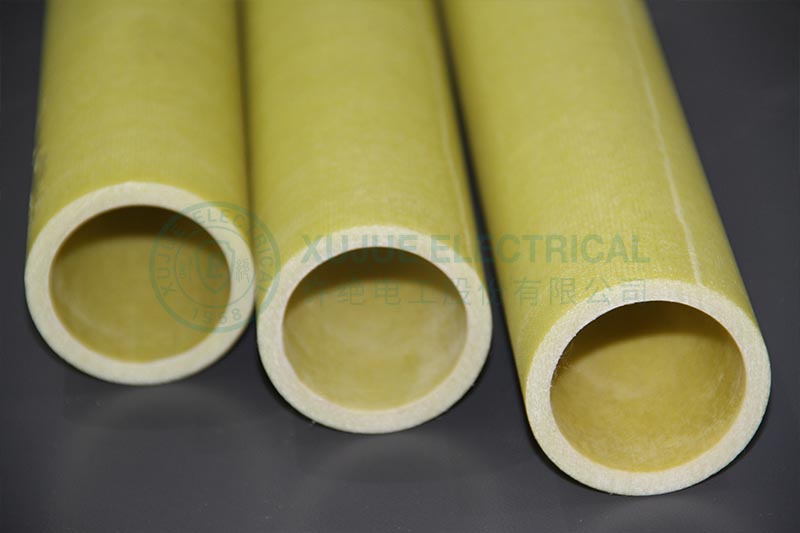

Filament wound fiberglass tubing is composite material tubes made by impregnating continuous glass fibers with resin, mechanically winding them at a specific angle on a mandrel, and then curing them.

Continuous fibers are oriented.

High fiber content, resulting in a compact tube structure.

Fiber angles can be designed according to stress requirements.

Uniform wall thickness, good dimensional stability.

This production process gives filament wound fiberglass tubing significant advantages in strength and performance consistency.

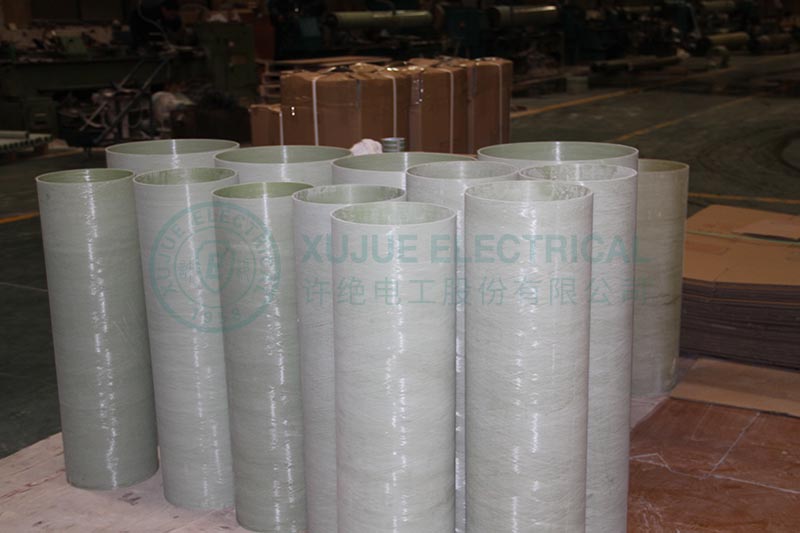

The commonly referred to ordinary fiberglass tubes mainly refer to products manufactured through the following methods: roll forming, hand lay-up molding, or simple molding or pultrusion followed by further processing. Their fiber arrangement is relatively random, and structural shaping relies heavily on the resin system.

Relatively simple production process

Lower cost

Fiber orientation is not easily fully controlled

Some fluctuation exists in the consistency of tube performance

Because the continuous fibers are wound in the direction of force, filament wound fiberglass tubing has higher tensile strength, bending strength, and impact resistance than ordinary fiberglass tubes. They are more suitable for working environments subject to higher mechanical stress.

In high-voltage or medium-voltage applications:

Filament wound fiberglass tubing offers more stable insulation performance.

Lower risk of partial discharge.

Suitable for long-term operation of electrical equipment.

Ordinary fiberglass tubes are more suitable for low-voltage or general insulation requirements.

The winding process allows for precise control of the tube’s inner and outer diameters, wall thickness, and concentricity. Therefore, these tubes are more suitable for high-precision machined parts or equipment with strict assembly requirements.

Insulating sleeves for electrical equipment

Supporting components for high-voltage switchgear

Transformer structural components

Load-bearing pipe fittings for mechanical equipment

Key structural components for new energy equipment

General structural support

Protective sleeves

Low-stress pipes or shells

Projects with high cost sensitivity

When selecting a material, it is recommended to consider the following factors:

Does the project involve high voltage or high mechanical stress environments?

Are the requirements for dimensional accuracy and performance consistency stringent?

Does the project require long-term continuous and stable operation?

What is the overall balance between budget and total lifecycle cost?

If the project prioritizes long-term reliability and safety, filament wound fiberglass tubing is usually a more suitable choice. In general applications, ordinary fiberglass tubing offers a cost advantage.

Although both wound and ordinary fiberglass tubing are fiberglass composite materials, they differ significantly in performance, service life, and application areas due to differences in manufacturing processes and structural design.

Understanding these differences correctly helps in achieving more rational material selection and cost control while ensuring safety and performance.

If you are selecting fiberglass tubing for power insulation, new energy, or industrial equipment projects, we welcome further technical evaluation based on specific operating conditions to achieve the best application results.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……