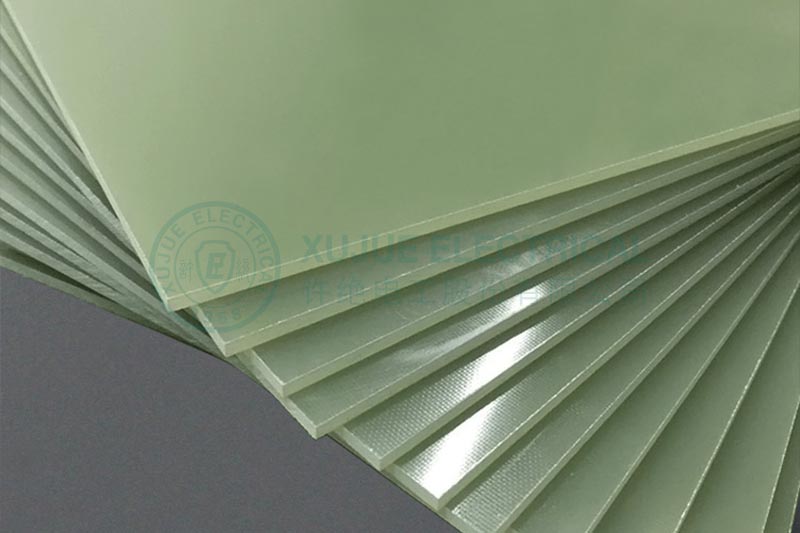

FR4 epoxy fiberglass board is a commonly used insulating material in the electronics, electrical, and industrial equipment fields. Its performance stability directly affects the safe and reliable operation of equipment. Among various technical parameters, the density of FR4 material is a key indicator for evaluating its structural compactness, mechanical strength, and electrical performance. This article details the measurement methods, industry standards, and testing precautions for FR4 density, providing a reference for engineering selection and quality control.

FR4 density directly reflects the compactness of the material’s internal structure and the proportion of fiberglass content, directly affecting the following properties:

Mechanical Strength: Including bending resistance, compressive strength, and impact resistance.

Electrical Insulation Performance: Including dielectric strength and withstand voltage.

Water Absorption: Density uniformity helps reduce the risk of water absorption.

Dimensional Stability: Reduces thermal expansion or deformation of the material.

Therefore, density testing during production and procurement is a crucial step in ensuring the quality of FR4 materials.

Principle: Calculate density based on the relationship between the volume displaced by the liquid and the mass of the material.

Steps:

Accurately weigh the FR4 sample mass (m).

Immerse the sample in the liquid supplied with the hydrometer (e.g., water) and measure the displaced liquid volume (V).

Calculate the density using the formula ρ = m / V.

Advantages: High measurement accuracy, suitable for laboratory and quality testing.

Precautions: The selected liquid must not dissolve the FR4 material. Maintain a stable temperature to avoid errors.

Principle: Calculate the volume by measuring the external dimensions of the FR4 sheet, and then calculate the density based on the mass.

Steps:

Measure the length (L), width (W), and thickness (H) of the sheet using calipers or a thickness gauge.

Calculate the volume: V = L × W × H.

Accurately weigh the sample mass (m), and calculate the density using the formula ρ = m / V.

Advantages: Simple operation, suitable for standard-sized sheets.

Disadvantages: Lower measurement accuracy for materials with uneven surfaces or varying thicknesses.

Digital densitometers, hydrometers, X-ray density meters, etc., are widely used in laboratories and factories for testing. These devices can quickly determine the density of FR4 and automatically record the test data, facilitating quality tracking.

IEC 60641-2/60641-1: Method for measuring the density of insulating materials.

ASTM D792: Method for testing the density and relative density of plastics.

GB/T 1447: Determination of density of epoxy resin glass cloth sheets. Chinese National Standard.

Raw material warehousing: Test every batch.

Production process: Test at least once per production shift.

Final product: Test according to the AQL sampling plan.

PCB Substrates: Density uniformity helps ensure copper foil adhesion and circuit stability.

Electrical Insulation Components: Stable density reduces the risk of partial discharge.

Industrial Machinery Parts: Ensures material compressive and bending resistance, extending service life.

Through density testing, procurement and production processes can effectively screen for FR4 materials that meet standards, avoiding equipment instability or malfunctions due to material defects.

Possible Causes:

Sample not sufficiently dried

Large fluctuations in test water temperature

Bubbles on the sample surface

Solutions:

Dry the sample in a 105℃ oven for 2 hours

Use a constant temperature water bath to control the temperature

Add a trace amount of wetting agent to reduce bubbles

Routine Quality Control: Use the Archimedes method, balancing accuracy and efficiency.

R&D Analysis: Combine multiple methods for cross-validation.

Online Testing: It is recommended to use a non-contact densitometer (such as X-ray method).

Low density: May indicate insufficient material curing, excessive resin content, or excessive internal voids.

High density: May indicate excessive glass fiber content or excessive compression during material molding.

Accurate measurement of FR4 density is fundamental to ensuring PCB product quality and performance. By selecting appropriate testing methods, strictly controlling testing conditions, and accurately interpreting test data, companies can effectively monitor material quality, optimize production processes, and improve product reliability.

Contact us for customized FR4 material solutions and product quotations. Whether you need standard thickness boards, high-frequency materials, or customized products with special properties, our technical team can provide you with a suitable solution.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……