In the manufacturing process of oil-immersed power transformers, the reliability of the insulation structure directly affects the safe operation and service life of the transformer. Transformer insulation DDP oil duct strips are important insulating components in the winding oil channel structure. They play a role in supporting the windings, constructing oil channels, and ensuring cooling and insulation performance. They are a key auxiliary material required for the production of high-quality transformers.

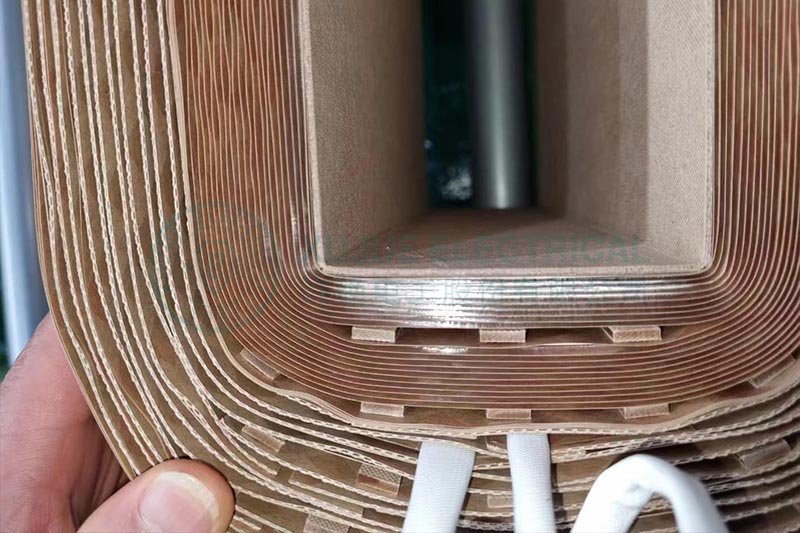

DDP oil duct strips are made from electrical grade insulating paper (DDP, i.e., diamond-patterned adhesive insulating paper) as the base material through a multi-layer lamination process. Its surface is coated with a diamond-shaped dotted epoxy resin adhesive layer, which can firmly bond to the windings under heat and pressure, forming a stable insulating support structure.

This material is mainly used between windings and between windings and the core of oil-immersed transformers. Its main functions are as follows:

♦ Constructing Oil Channels: It can separate the windings, form pre-set oil flow channels, ensure smooth circulation of insulating oil, and achieve effective heat dissipation.

♦ Maintaining insulation distance: Providing mechanical support between high-voltage and low-voltage windings, and between windings and the core, to maintain the specified insulation gap and prevent electrical breakdown.

♦ Enhancing mechanical stability: Supporting the windings to prevent deformation or displacement when the transformer is subjected to short-circuit electrodynamic forces.

Multi-layer Composite Structure: DDP oil duct strip utilizes multi-layer insulating paper lamination, resulting in high mechanical strength.

Rhomboid Dotted Coating: Uniformly distributed adhesive layer on the surface, ensuring excellent adhesion.

Uniform Thickness: Ensures consistent oil channel dimensions.

Neat Edges: Reduces the risk of partial discharge.

Oil, Heat, and Aging Resistance: Adaptable to the long-term operating environment of transformers.

This material has high dielectric strength, preventing electrical breakdown between windings.

It is not easily deformed during winding press-fitting, ensuring the stability of the oil channel structure.

It is suitable for A, E, B, and F class insulation systems, meeting long-term operating requirements.

It bonds tightly to the winding after hot pressing, preventing displacement due to vibration.

It can keep stable performance even when immersed in transformer oil for extended periods.

DDP oil duct strips are punched using high-precision molds to control dimensional tolerances. This ensures smooth edges and reduces the risk of partial discharge.

This process involves chamfering the edges and creating oil flow guide grooves at designated locations. This optimizes the oil flow path and reduces flow resistance.

The process reduces the material’s moisture content, and resin impregnation and curing are performed when necessary to improve component strength and moisture resistance.

DDP oil duct strips are used in the following locations:

Between high-voltage and low-voltage windings

Interlayer oil channel structure between windings

Between windings and core

Oil-immersed distribution transformers

Oil-immersed power transformers

Autotransformers and special transformers

Why do transformer oil duct strips shift or deform? This is usually related to improper material selection, imperfect manufacturing processes (such as insufficient drying), and deviations in short-circuit electrodynamic calculations.

How to inspect the quality of transformer oil duct strips? This includes dimensional accuracy, thickness uniformity, edge integrity, electrical strength, compressive strength, and long-term thermal aging performance evaluation.

Key points for selecting a supplier: Focus should be placed on the supplier’s material supply stability, mold processing precision, quality control system (such as ISO certification), and experience in collaborative design with transformer manufacturers.

Transformer insulation DDP oil duct strips are a key component of the transformer insulation system, playing a crucial role in ensuring winding cooling, insulation reliability, and mechanical stability. Selecting high-quality DDP oil duct strips helps improve the overall performance and service life of the transformer.

For DDP oil duct strips samples, technical parameter tables, or custom processing services, please contact a professional insulation material supplier for consultation.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……