Currently, high-voltage electrical equipment, new energy systems, and industrial automation fields place higher demands on the performance of insulation materials. EPGC308 insulation board, as a high-performance electrical laminate, possesses excellent electrical insulation properties, mechanical strength, and heat resistance. It has been widely used in transformers, motors, and high-end electrical equipment. This article systematically introduces the main application value of EPGC308 insulation board from the aspects of material characteristics, technical advantages, application scope, and selection points.

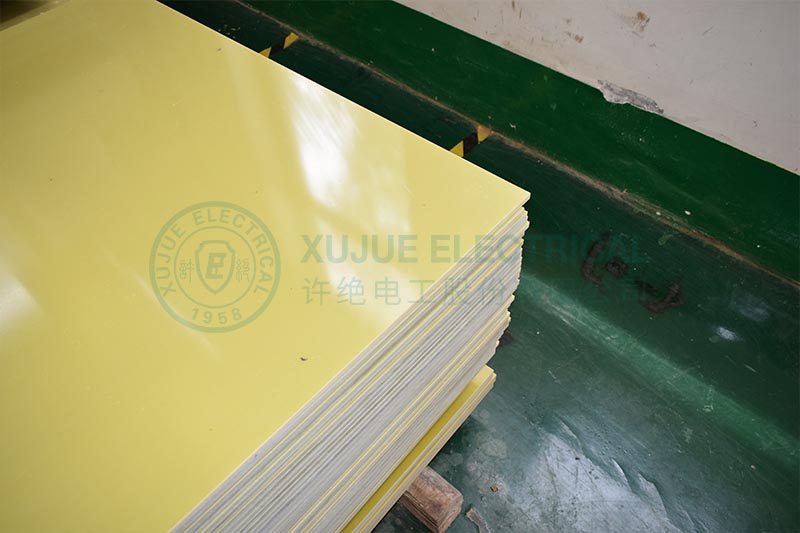

EPGC308 insulation board belongs to the epoxy glass fiber laminate series. It uses alkali-free glass fiber cloth as the reinforcing substrate and high-performance epoxy resin as the binder, manufactured through a high-temperature and high-pressure process. This material meets the relevant technical requirements of the EPGC series in IEC standards and is suitable for electrical equipment with high requirements for heat resistance and electrical performance.

EPGC308 insulation board is widely used in the power industry, primarily due to its comprehensive performance:

This insulation board has a compact structure and high resistance to bending, compression, and impact. It can withstand the electrodynamic forces and long-term mechanical stresses during transformer operation, helping to maintain equipment structural stability.

It possesses high dielectric strength, high volume resistivity, and low dielectric loss factor. Even in high-temperature, high-humidity, or transformer oil environments, it maintains stable insulation performance, reducing the risk of insulation breakdown.

Based on the dense structure of epoxy resin, this material has good resistance to transformer oil, common solvents, and other chemical media, and is not prone to swelling, delamination, or performance degradation.

EPGC308 insulation board generally has a heat resistance rating of H (180℃), allowing for long-term use in high-temperature environments and meeting the temperature rise control requirements of electrical equipment.

This material can be cut, drilled, milled and turned, making it easy to manufacture various insulating components such as support bars, pads, pressure plates, and insulating screws.

EPGC308 insulation board is commonly used in the following equipment:

Insulation structural components of power transformers

High-voltage switchgear and distribution cabinets

Motor insulation support components

New energy inverters and energy storage systems

Rail transit and industrial automation equipment

EPGC308 insulation board has stable performance and can replace traditional phenolic boards and some low-performance epoxy boards.

Qualified EPGC308 insulation boards typically meet the following standards:

IEC 60893:Thermosetting resin industrial rigid laminates for electrical engineering

GB/T 5132:Test methods for electrical insulating laminates

ASTM D709

UL certification, RoHS certification

Check that the material density (usually ≥1.3g/cm³), flexural strength, vertical layer dielectric strength, and heat resistance rating meet design requirements.

Determine the thickness, length, and width based on the drawings. Inquire with the supplier about pre-cutting or custom processing services to save processing costs and time.

Prioritize suppliers with professional production experience, who can provide complete material certification reports (such as SGS, COC certificates) and factory inspection reports. Also, pay attention to their technical support capabilities.

Before bulk purchases, request samples for oil immersion tests, machining tests, etc., to verify that the material meets actual usage conditions.

EPGC308 insulation board has excellent electrical properties, mechanical strength, and heat resistance stability, making it valuable in modern electrical equipment. Whether in high-voltage transformers, new energy systems, or industrial automation equipment, this material provides reliable assurance for the safe and stable operation of the equipment.

We professionally supply EPGC308 laminates that meet IEC, GB, and customer-specific requirements. We not only guarantee material performance but also provide a one-stop service from sheet supply to precision machining. Contact us for free technical consultation, the latest product information, and customized solutions.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……