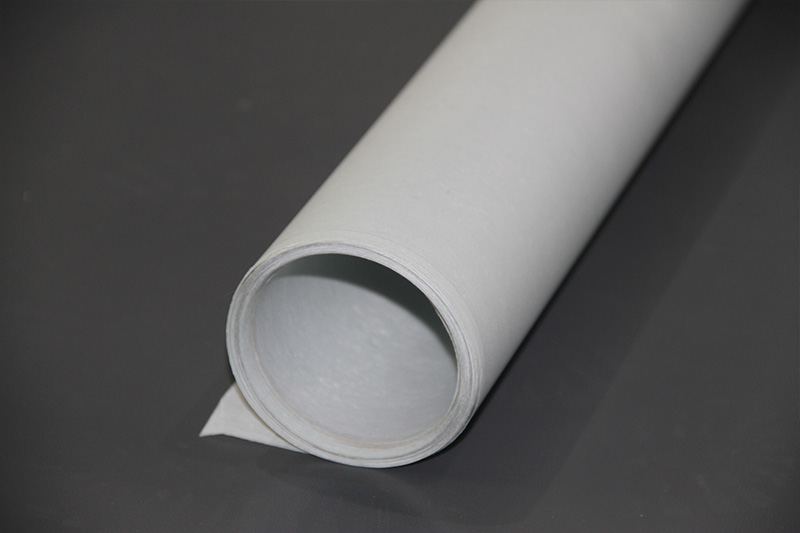

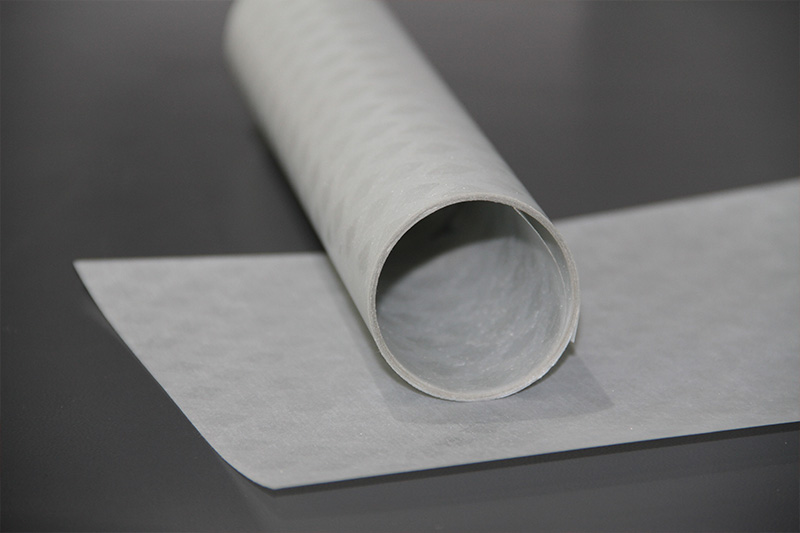

DMD insulation paper is a flexible composite material with Class F insulation rating of 155°C. It consists of a polyester film coated with an adhesive, bonded to a polyester fiber nonwoven fabric on both sides. It combines the excellent impregnation properties of the nonwoven fabric with the superior dielectric strength of the polyester film, making it widely used in electrical equipment, particularly for slot insulation, turn-to-turn insulation, and pad insulation in Class F motors.

Functionally, DMD insulation paper enhances the film’s mechanical strength and stiffness while maintaining excellent flexibility and improving heat resistance. The fiber paper’s excellent adsorption properties ensure excellent adhesion to the slot walls and coils, preventing displacement during equipment operation. The film’s excellent dielectric properties compensate for the fiber paper’s insufficient dielectric strength.

DMD insulation paper production utilizes a continuous, automated process, primarily consisting of the following steps:

Polyester Film (M Film): Select electrical-grade polyester film of a specific thickness (e.g., 1.0 mil, 1.5 mil, 2.0 mil) and grade, requiring a smooth surface, uniform thickness, and excellent electrical properties.

Polyester Fiber (D Mat): Prepare chopped polyester fibers and form a fluffy, uniform fiber web using carding or air-laid technology.

Adhesive: Prepare or purchase a specific adhesive solution (typically a modified epoxy or polyester resin system) with excellent electrical properties, thermal stability, and adhesion.

The upper and lower layers of polyester nonwoven fabric are first placed in an impregnation tank filled with adhesive solution, allowing them to be thoroughly and evenly saturated with the adhesive. The impregnated webs then pass through a high-temperature drying tunnel to evaporate the solvent and initially cure the adhesive (reaching the B-Stage), forming a “semi-cured” prepreg. This step is crucial for controlling the adhesive content, directly affecting the thickness, mechanical strength, and adhesion of the final product.

The middle layer of polyester film is unrolled and precisely aligned with the pre-impregnated and dried upper and lower layers of polyester nonwoven fabric to form a “D-M-D” structure. The laminated materials are then heated and pressurized by a set of heated rollers (hot press rollers). The heat and pressure completely melt and flow the semi-cured adhesive, firmly bonding the three layers together.

The laminated materials are then fully cured in a long oven or by maintaining a constant heated roller temperature, ensuring the final chemical crosslinking of the adhesive for optimal mechanical and electrical properties. After the fully cured DMD material is cooled and shaped by cooling rollers, it is automatically wound into wide rolls for easy transportation and slitting.

Based on customer needs, the wound rolls are slit on a slitting machine into products of varying widths and diameters. Some DMD insulation paper with special requirements may also undergo surface treatment (such as adding a slip agent) or embossing.

The performance advantages of DMD insulation paper stem from the scientific design logic of its composite structure, which is specifically reflected in the following aspects:

It offers both Class B and Class F materials, adapting to different temperature scenarios. Class F material significantly extends its service life in high-temperature environments.

Tear Resistance: The addition of polyester fiber nonwoven fabric significantly improves the material’s edge tear resistance, preventing damage to the motor windings during assembly.

Abrasion Resistance: The high surface hardness resists wear caused by coil vibration.

Flexibility: It can adapt to complex winding structures and will not crack when bent.

Dielectric Strength: It is significantly higher than ordinary insulation paper and can withstand high voltage surges.

Insulation Resistance: It maintains high resistance in both normal and humid environments, ensuring electrical safety.

Corona Resistance: It maintains long-term stability in high-voltage electric fields, preventing breakdown caused by partial discharge.

With the continuous improvement of motor energy efficiency standards, DMD insulation paper is developing towards high thermal conductivity and low loss. For example, some manufacturers have developed modified materials that improve thermal conductivity while maintaining existing insulation performance to meet the demands of ultra-high-efficiency motors. For equipment manufacturers, a thorough understanding of the process and performance of DMD insulation paper is a key measure to optimize product reliability and reduce overall lifecycle costs.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……