At the heart of power transformers lies a seemingly insignificant material that plays a crucial role in the equipment’s reliability, efficiency, and service life—insulation paper. Among various insulation materials, DMD insulation paper has established itself as the industry benchmark for its exceptional performance. If you’re seeking a high-quality insulation solution for your project, a thorough understanding of its manufacturing process and core characteristics is crucial.

Power transformer insulation paper is a cellulose-based or composite solid material designed specifically to isolate the transformer’s conductive components (such as between windings and between the windings and the core). Its core function is to withstand extremely high electrical, thermal, and mechanical stresses, prevent short circuits, and ensure stable transformer operation. Common types include pure cellulose paper, heat-resistant Nomex paper, and composite insulation papers such as DMD and DDP.

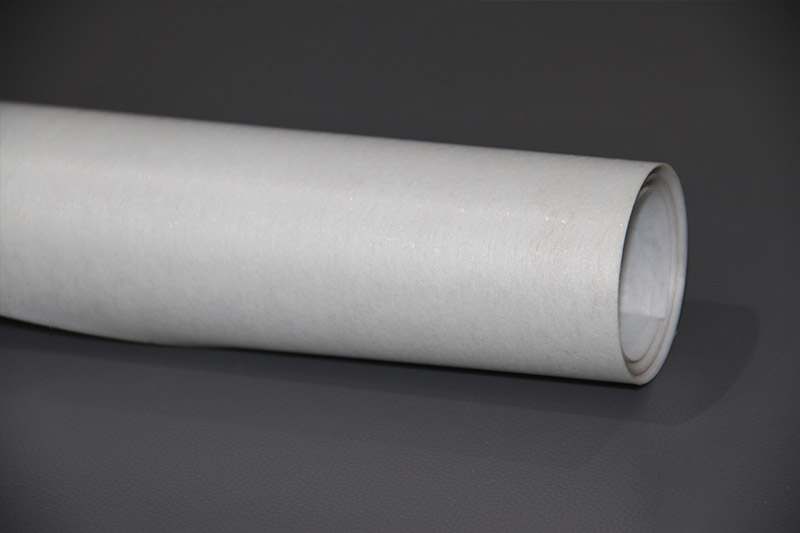

DMD insulation paper utilizes a three-layer composite structure: a middle layer of electrical polyester film and an outer layer of high-density polyester fiber nonwoven fabric. A calendering process creates a dense bond between the three layers, resulting in the following excellent properties:

DMD insulation paper is available in two heat resistance grades: B and F.

Grade B material is suitable for transformers operating under standard conditions, such as 10kV box-type substations in urban distribution networks.

Grade F material, through the addition of special coatings or optimized composite structures, can withstand higher temperatures and is primarily used in high-temperature, high-load applications such as renewable energy grid integration and industrial parks.

In actual applications, the long-term operational stability of Grade F material in high-temperature environments far exceeds that of Grade B, effectively slowing insulation aging and extending equipment life.

DMD insulation paper’s longitudinal and transverse tensile strengths can withstand the mechanical stresses experienced during transformer coil winding, and its tear resistance is superior to that of pure paper-based materials. Its breakdown voltage meets International Electrotechnical Commission standards, effectively isolating potential differences between coil layers and preventing partial discharge.

Through a distilled water humidity conditioning and supercalendering process, DMD insulation paper eliminates internal stress, improves tightness, and reduces the risk of moisture absorption and deformation after oil immersion. This treatment ensures dimensional stability in humid or high-temperature environments, ensuring uncompromised insulation performance.

The DMD insulation paper manufacturing process is precise and requires strict control. The main steps are as follows:

· High-quality polyester film (Mylar) rolls and polyester fiber (Dacron) non-woven fabric rolls are prepared.

· All raw materials undergo rigorous incoming inspection to ensure that their dielectric properties, thickness, and uniformity meet standard requirements.

· A high-performance adhesive (typically epoxy or polyester adhesive) is evenly applied to both sides of the polyester film.

· Two layers of polyester fiber non-woven fabric are precisely laminated to the coated polyester film using a heated roller. This step requires extremely strict control of temperature, pressure, and speed to ensure a bubble-free, delamination-free, and secure bond.

· The laminated materials enter a heated tunnel (curing oven) to fully cure the adhesive, forming a permanent three-layer composite structure.

· The materials may then be allowed to rest for a period of time to achieve final bond strength.

The solidified material is cooled and shaped by cooling rollers before being wound into wide rolls by an automatic winder for subsequent slitting.

· Large rolls of DMD material are slit into the required widths and lengths according to customer order specifications.

· Quality control is a core part of the manufacturing process. Numerous tests are performed throughout the production process, including dielectric strength testing, thickness and uniformity testing, adhesive strength testing, and tensile strength testing. Only products that pass all tests are packaged and shipped.

DMD insulation paper has a wide range of applications, primarily including:

· Oil-immersed and dry-type power transformers

· Distribution transformers

· Insulator transformers

· Motor and generator insulation

In the performance-demanding power industry, the choice of insulation material is crucial. DMD insulation paper remains the preferred material for transformer construction due to its proven reliability, durability, and comprehensive performance. A deeper understanding of its manufacturing process and key characteristics can help you make a more informed choice and provide optimal protection for your equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……