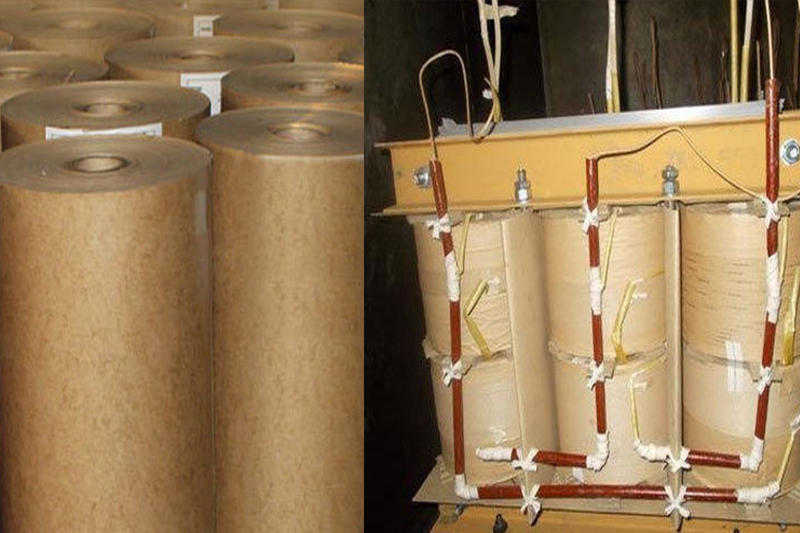

Insulating kraft paper is a specialty paper that combines the insulating properties of kraft paper with the mechanical strength of kraft paper. Made from pure wood pulp or kraft pulp blended with a portion of sulfate wood pulp, it undergoes special insulation treatments such as impregnation with insulating oil and resin, resulting in excellent electrical and physical properties.

The widespread use of insulating kraft paper stems from its exceptional performance, as shown below:

High Dielectric Strength: As a core characteristic of insulating materials, it can withstand high-intensity electric fields without breakdown, and its breakdown voltage is typically high, making it suitable for a wide range of voltage levels.

Good Voltage Resistance: It can withstand high overvoltage surges for a short period of time.

Low Dielectric Loss: In high-frequency electric fields, it minimizes energy loss and generates less heat, which is crucial for capacitors and high-frequency transformers.

Inheriting the inherent advantages of kraft paper, it offers high tensile strength, tear and puncture resistance, and excellent toughness. During coil winding and transformer core processing, it is less susceptible to breakage or damage, facilitating subsequent processing and winding.

The paper’s loose and porous structure allows for excellent absorption and retention of impregnants such as insulating oils, resins, and varnishes.

After impregnation, its dielectric strength, heat resistance, moisture resistance, and mechanical strength are significantly enhanced, resulting in a more complete insulation system.

Conventional insulating kraft paper is typically rated A (105°C).

With special treatments, such as the use of high-temperature-resistant fibers or impregnation with specialized resins, its heat resistance can be raised to E (120°C) or even higher.

The paper’s widely available raw materials are biodegradable, making it more environmentally friendly than some synthetic film materials.

Its relatively low cost offers significant cost-effectiveness.

Hygroscopicity: Untreated paper easily absorbs moisture from the air, significantly reducing its insulation properties. Therefore, it must be treated with impregnation, coating, or sealed in a dry environment.

Poor Weather Resistance: Not suitable for outdoor use or exposure to harsh environments.

Due to its aforementioned performance advantages, insulating kraft paper has become an indispensable basic material in the power and electronics industries. Its main applications are as follows:

Turn-to-Turn Insulation: Wrapped between magnet wires such as enameled and paper-covered wires, it acts as an insulating layer between coil turns.

Interlayer Insulation: Provides insulation between coil layers.

Spacer Insulation: Provides isolation and support for coils and other components.

Lead Insulation: Used to wrap device lead wires.

It is the core dielectric material for oil-immersed paper capacitors. Its porous structure allows it to fully absorb electrolyte or insulating oil, resulting in an extremely high dielectric constant and insulation strength.

Cable paper: Used for core insulation and shielding in medium- and high-voltage power cables.

Magnet wire wrapping: Used in combination with enameled wire, it produces paper-wrapped wire with enhanced high-voltage resistance. It is commonly used in the windings of large motors and transformers.

Motor insulation: Used for slot insulation and phase insulation in medium- and large-sized motors.

Household appliances: Used in components requiring insulation and structural support, such as interlayer insulation in microwave ovens and transformers.

Insulating kraft paper is a classic and irreplaceable electrical insulation material. It successfully combines excellent insulation properties, high mechanical strength, and superior impregnation characteristics. When combined with insulating oils and resins, it can meet the demanding requirements of a wide range of electrical equipment, from household appliances to ultra-high-voltage transformers.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……