G10 is a high-performance laminate widely used in the industrial sector. It uses glass fiber cloth as a reinforced base, is impregnated with epoxy resin, and then cured under high temperature and high pressure.

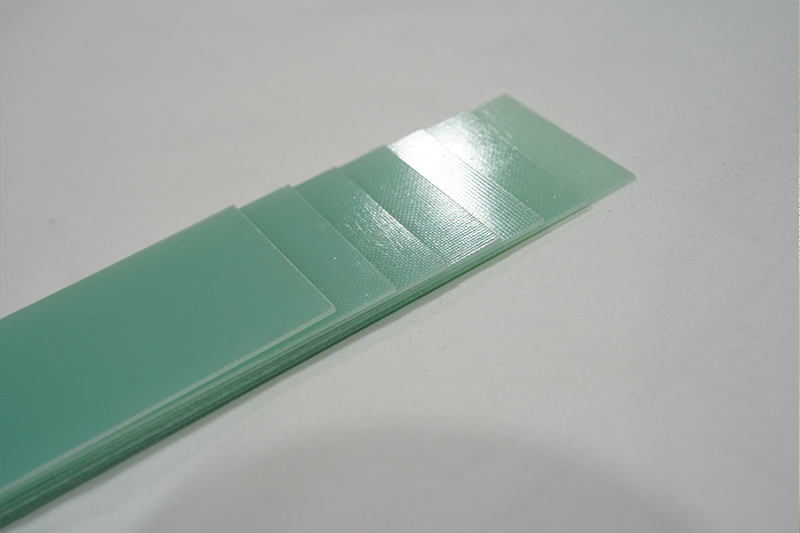

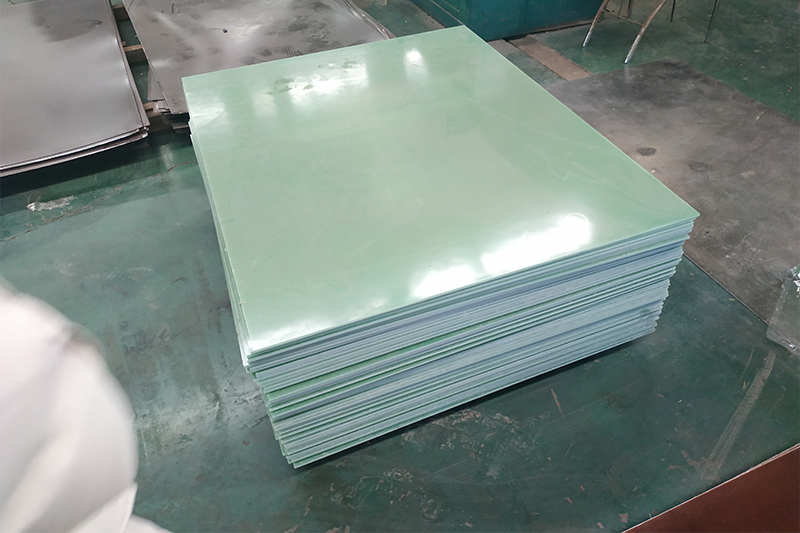

Green G10 is typically produced by the addition of specific dyes or pigments during the sheet production process. Aside from the color difference, the core mechanical and electrical properties of this green G10 are essentially the same as those of regular natural (or beige) G10.

G10 sheet is made from electronic-grade alkali-free glass fiber cloth and high-performance epoxy resin, laminated through a high-temperature and high-pressure lamination process. It exhibits the following characteristics:

High Strength and Lightweight: The glass fiber reinforcement imparts impact and abrasion resistance to the material, and its density is only one-quarter that of metal, significantly reducing the overall weight of the equipment.

High-Temperature and Fire Resistance: It maintains a stable operating temperature above 130°C for extended periods, and can even withstand short-term temperatures exceeding 280°C. It also meets the UL94-V0 flame retardancy standard and exhibits self-extinguishing properties, effectively enhancing equipment safety.

Excellent electrical insulation: Even in high-frequency and high-voltage environments, the G10 maintains low dielectric loss and high insulation resistance, preventing signal interference and leakage risks.

Environmentally friendly and weather-resistant: The alkali-free glass fiber is halogen-free, and the epoxy resin system can be processed using a water-based process or bio-based raw materials, reducing VOC (volatile organic compound) emissions. It also withstands harsh environments such as moisture and corrosion, ensuring a long service life.

Insulating Structural Parts

Partitions and Barriers: In electrical switchgear, control boxes, and high-voltage equipment, green G10 can be cut into various shapes to create insulating partitions, separating conductors at different potentials to prevent arcing and short-circuiting. The green color itself serves as a safety warning.

Brackets and Terminal Blocks: Used to secure and support heavy electronic components such as transformers, resistors, and fuse holders, G10’s high strength ensures long-term structural stability, while its insulation properties ensure safe operation.

Transformer Spacers: Insulating material is required between the windings of large transformers to provide isolation and heat dissipation. G10 laminate is a common choice.

In heavy industrial environments, G10’s strength, stability, and insulation make it an irreplaceable material. Key applications include:

Wear-Resistant Parts

Gears and Bearings: Where metal is prohibited (to avoid sparks or magnetic interference) or where self-lubrication is required, G10 is often used to manufacture lightly loaded gears, bearings, bushings, and other components. It offers excellent wear resistance and a low coefficient of friction. Gaskets and Washers: Used in mechanical equipment connections, they provide insulation, shock absorption, and wear resistance.

Structural supports and mounting plates

Equipment panels and covers: They serve as enclosures, maintenance covers, and other components for electronic equipment, providing both protection and insulation.

The differences between the two are a common question in the industry. The core differences are summarized in the following table:

| Dimension | G10 | FR-4 |

| Flame Retardancy | Non-flame retardant or low flame retardancy grade | Flame Retardant (FR stands for Flame Retardant) |

| Flame Retardancy Standard | Does not meet UL94 V-0 grade; burns when exposed to open flame | Complies with UL94 V-0 flame retardancy standard |

| Core Performance | Mechanical properties are generally slightly higher than FR-4 | Electrical properties suitable for PCB manufacturing |

| Typical Applications | Mechanical parts, tool handles, etc. | PCB circuit boards (standard substrate) |

Important Note: Green G10 and green FR-4 are highly similar in appearance. When purchasing, please confirm the product’s flame retardancy rating based on the intended use (whether strict flame retardancy is required) to avoid misuse.

Dust Protection: G10 processing generates fiberglass dust, which is irritating to the respiratory tract and skin. When working with G10, wear an N95 or higher dust mask, goggles, and protective gloves, and operate in an environment equipped with dust extraction.

Tool Selection: Because fiberglass wears tools quickly, use carbide or high-quality metalworking tools to ensure precision and efficiency.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……