In the power equipment sector, transformers, with their outstanding advantages, have been widely used in numerous applications, including data centers, rail transit, and industrial parks. As the core material for interlayer insulation of transformer low-voltage windings, epoxy resin DMD transformer insulation paper, with its excellent electrical performance, reliable heat resistance, and strong mechanical strength, is crucial for ensuring the long-term and stable operation of transformers.

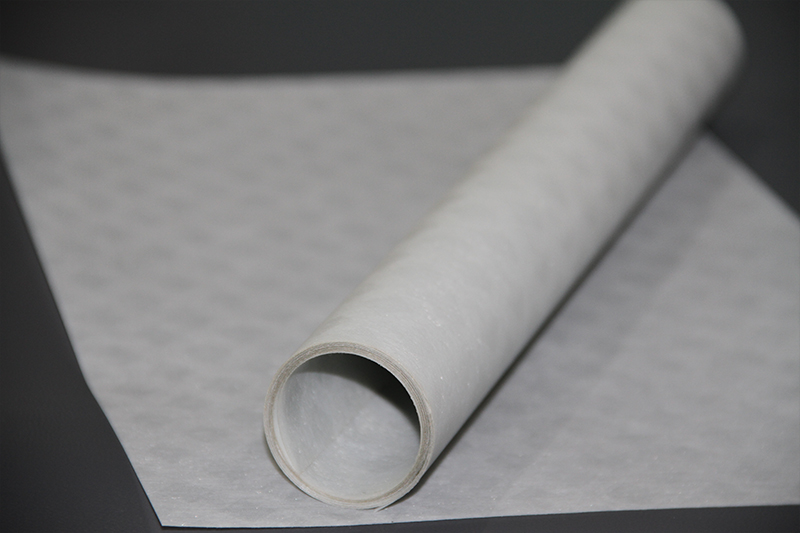

Epoxy resin DMD insulation paper utilizes a three-layer composite structure, with each layer having a distinct function:

Middle layer: Made of high-dielectric-strength polyester film (PET) with a thickness ranging from 0.05-0.35mm, it provides basic insulation support for the entire material.

Outer layer: Covered with high-density polyester fiber nonwoven fabric, it effectively enhances the material’s mechanical strength and impregnation properties.

Impregnation layer: Impregnated with heat-resistant modified epoxy resin and subjected to a staged baking process to a semi-cured state, achieving a deep bond between the resin and the substrate.

This unique structure endows the material with numerous excellent properties:

Heat resistance: Reaching F-class, it can withstand short-term thermal shocks up to 180°C, fully meeting the high-temperature operation requirements of dry-type transformers.

Electrical performance: Both volume and surface resistivities are high, with low leakage current. Furthermore, the polyester film provides exceptional tensile strength and tear resistance, making the material less susceptible to damage during wrapping and wire embedding.

Mechanical strength: Leveraging the superior properties of the polyester film, the material possesses exceptional tensile strength and tear resistance, effectively preventing breakage during wrapping and wire embedding.

Environmental advantages: The curing process produces no benzene or ketone volatiles, meeting solvent-free process standards and ensuring environmental friendliness.

As the core insulation material for low-voltage coils in dry-type transformers, epoxy DMD paper is tightly bonded to copper foil through a vacuum impregnation process, forming an insulation structure with low shrinkage and high bonding strength.

In F-class motors, DMD paper can be used for stator slot insulation, phase-to-phase insulation, and rotor winding protection. Its heat resistance meets the long-term operation requirements of motors, and it can be die-cut to accommodate various slot designs.

In applications such as transformers and switchgear, DMD paper serves as an insulating barrier, providing high-voltage and corona protection. For example, the diamond-patterned DMD paper, with its dotted resin coating, allows for oil penetration and gas discharge in oil-immersed transformers, effectively preventing partial discharge.

Storage: Store in a cool, dry, and clean warehouse. Avoid sunlight, moisture, and contact with corrosive chemicals.

Workability: Although the material exhibits excellent toughness, sharp tools should be used during cutting and punching to prevent burrs that could affect performance.

Compatibility Testing: Before performing the VPI process, it is recommended to confirm the compatibility of the selected epoxy resin DMD with the specific epoxy impregnation varnish to ensure a perfect combination.

Thickness Selection: Select the appropriate thickness based on the design voltage level and insulation requirements. Common specifications include 0.18mm, 0.20mm, and 0.25mm.

Conventional insulation materials are prone to stress cracking due to shrinkage during the curing process. Epoxy DMD, however, uses a staged baking process to control shrinkage to less than 0.5%, ensuring long-term insulation stability.

The epoxy and amine reactive groups in the modified epoxy resin form a chemical bond with the copper foil surface, increasing bond strength by 30% compared to conventional insulation paper and significantly reducing the risk of coil loosening.

The material can be stored for 12 months in a dry environment below 30°C. Even after the expiration date, it can still be used after passing inspection, helping to reduce inventory management costs.

Major manufacturers offer product thicknesses of 0.18-0.40mm. And they also provide slitting services in widths of 10-1000mm, which adapts to the winding process requirements of transformers of varying capacities.

Epoxy resin DMD transformer insulation paper is more than just an insulating component. It serves as a crucial bridge connecting materials science, power electronics, and intelligent manufacturing. As transformers continue to evolve toward higher capacity, higher energy efficiency, and smaller size, DMD insulation paper must continue to push the boundaries of heat resistance, reduce dielectric loss, and leverage digital processes to improve production consistency. For equipment manufacturers, selecting a DMD supplier with F-level certification, customization capabilities, and environmental compliance requirements will become a key part of building product competitiveness.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……