In fields like electrical engineering and construction, choosing the right material is crucial to project success. Especially when it comes to applications that require both structural strength and electrical safety, electrical laminated wood and plywood are often compared. While similar in appearance, they differ significantly. Choosing the wrong material can not only lead to project failure but also create safety hazards.

This article will delve into the differences between electrical laminated wood and plywood, helping you make a sound choice based on your specific needs.

Electrical laminated wood , also known as insulating laminated wood or electrical plywood, is an engineering material specifically designed for electrical applications.

Electrical laminated wood is typically made from high-quality birch veneer. The veneer is first impregnated with a synthetic resin such as phenolic resin, then cured and laminated under high temperature and high pressure to form the finished product. This specialized process imparts its exceptional electrical properties.

High Dielectric Strength: Excellent arc resistance and electrical insulation properties effectively prevent current leakage and short-circuit accidents.

Low Dielectric Constant: Maintains stable performance even in high-voltage electric fields.

High Mechanical Strength: Excellent compressive and bending resistance, ensuring a stable and reliable structure.

Moisture-Resistant and Corrosion-Resistant: Resin-treated, its resistance to moisture and chemical corrosion far exceeds that of ordinary wood.

Excellent Flame Retardancy: Most commercially available electrical laminate products meet relevant flame retardant standards.

Plywood is a versatile material widely used in construction and manufacturing. It is made from multiple layers of veneer glued together in a crisscross pattern.

During production, logs are first peeled into thin veneers. After the veneers dry, they are coated with an adhesive (such as urea-formaldehyde resin). The veneers are then assembled with the wood grain perpendicular to each other. Finally, plywood is formed through a hot pressing process.

High Structural Strength: The crisscross pattern ensures uniform strength in all directions, making it less susceptible to cracking and deformation.

Cost-Effectiveness: The price is typically lower than that of specialty wood panels and is readily available.

Easy to Process: Sawing, drilling, and sanding are easily accomplished.

Wide Applications: From furniture and construction to the production of various everyday items, plywood has a wide range of applications.

Note: Ordinary plywood does not provide reliable electrical insulation and is prone to mold and deformation in humid environments.

The choice of material should be determined based on the specific application scenario:

Applications involving electricity: For example, components such as internal dividers, brackets, and insulating partitions in distribution boxes (distribution cabinets).

High-voltage environments: For insulation components in transformers, switchgears, or other high-voltage electrical equipment.

Environmental Requirements for High Durability and Stability: Even in non-electrical environments, the superior performance of electrical laminate makes it an ideal choice in industrial environments with humidity, chemical corrosion, or specific fire protection requirements.

Purely Structural or Decorative Applications: For example, furniture, cabinets, shelving, partition walls, and building formwork.

Cost-Sensitive Projects: When the project budget is limited and electrical insulation is not a concern, plywood is a cost-effective option.

Important Warning: Never substitute regular plywood for electrical laminate for electrical applications. Doing so poses a significant risk and significantly increases the risk of fire and electric shock.

Q1: Does “electrical-grade” plywood exist?

A: Generally speaking, there is no such thing as “electrical-grade” plywood. “Electrical laminated wood” is a material specifically designed to meet electrical insulation requirements. Although it looks similar to plywood, it differs fundamentally in material selection and workmanship standards.

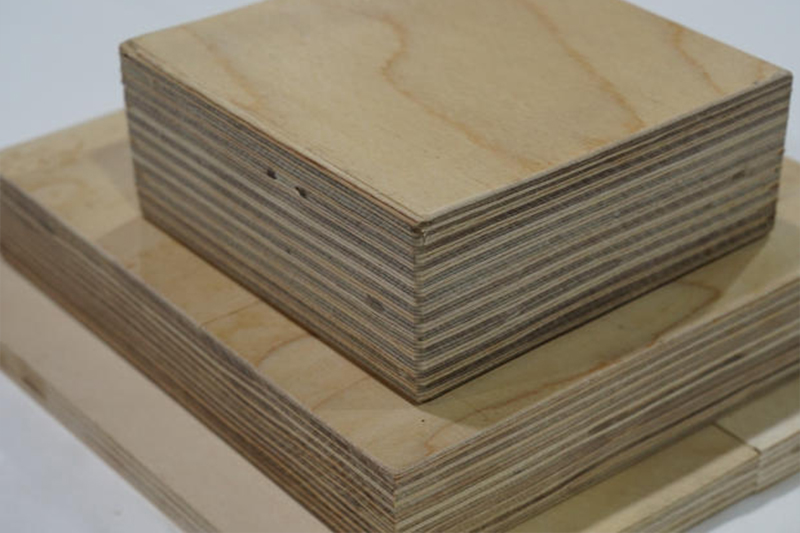

Q2: What are the appearance characteristics of electrical laminated wood?

A: Electrical laminated wood typically has a dark brown color on one or both sides and may have a smooth or textured surface. High-quality electrical laminated wood is often based on a light-colored birch base, with a dense and uniform laminate structure.

Q3: Where can I buy electrical laminated wood?

A: Electrical laminated wood is generally difficult to find in regular building materials markets. You can purchase it through professional electrical material suppliers such as Xu Jue Electrician, or through specialized B2B online platforms such as Alibaba.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……