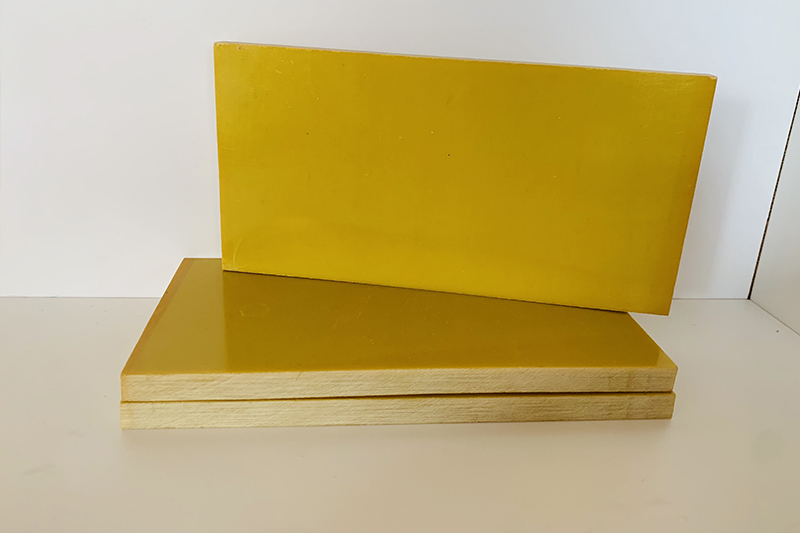

Epoxy FR4 is a composite insulation material composed of an epoxy resin matrix reinforced with electronic-grade glass fiber cloth. Its widespread application in transformer insulation (such as skeletons, retaining walls, bushings, and other key components) stems from its exceptional comprehensive performance, specifically categorized into the following five key aspects:

High Dielectric Strength: It can withstand extremely high voltages without breakdown and is a key performance indicator for effective isolation between the primary and secondary windings of a transformer.

Excellent Resistivity: Both volume and surface resistivity remain stable in harsh environments such as high temperature and high humidity, preventing insulation degradation.

Stable Dielectric Constant: The dielectric constant exhibits minimal fluctuation across various operating frequencies and temperatures, ensuring stable transformer operating parameters.

Transformer insulation must support the coils and withstand winding stress and operational vibration. FR4 offers significant advantages in this regard:

High Support Capacity: The glass fiber reinforcement provides FR4 with high mechanical strength, and the resulting frame securely holds the coils in place, preventing deformation.

Excellent Dimensional Stability: Shape and dimensions remain virtually unchanged in environments subject to temperature and humidity fluctuations, ensuring the transformer’s structural stability for long-term operation.

Transformers generate heat during operation and must meet fire safety requirements. FR4’s heat resistance and flame retardancy are crucial:

High Glass Transition Temperature (Tg): Conventional FR4 has a Tg between 130°C and 180°C, which allows it to withstand the high temperatures of wave soldering and reflow soldering, as well as the heat buildup during transformer operation.

UL94 V-0 Flame Retardancy: FR4 inherently meets the highest flame retardancy standards, effectively preventing the spread of fire and serving as one of its core safety features.

Transformers may be exposed to transformer oil, solvents, and acidic and alkaline environments. FR4’s corrosion resistance ensures long-term reliability:

It effectively resists the corrosion of transformer oil, common solvents, and acids and alkalis, preventing chemical aging and extending the service life of insulation components.

Transformer insulation components come in a variety of shapes, and FR4’s processability allows for customized customization.

Easy Precision Forming: FR4 sheet can be precisely formed into complex shapes for frames and insulation components through CNC machining, stamping, drilling, milling, and other processes to accommodate diverse transformer structures.

FR4 is one of the most widely used and easily accessible electronic insulation materials worldwide. Its market availability is primarily reflected in the following three key aspects, ensuring zero supply risk:

FR4 is primarily supplied in sheet form, covering a wide range of thicknesses—from thin sheets of 0.1mm to thick sheets of 3.0mm and above. Mainstream suppliers maintain large inventories and can quickly meet diverse thickness requirements.

The global FR4 production system is well-established, offering a diverse supply chain:

International brands: Global giants such as Panasonic, Isola, ITEQ, and SYTECH offer stable product quality and cover high-end needs.

Domestic Manufacturers: Domestic companies such as Jiantao Chemical and Shengyi Technology have achieved large-scale production, offering cost-effective products that meet both mid-range and low-end needs, as well as some high-end demands.

A mature supplier network ensures supply chain stability and continuity.

Almost all PCB fabricators and precision machining plants have the processing capabilities for FR4. They can customize the sheets into various transformer insulation components based on design drawings, eliminating the need for additional processing facilities.

Among commonly used transformer insulation materials, FR4’s cost is moderately low, making it an excellent choice for balancing performance and cost. Specific cost characteristics are as follows:

The key to FR4’s manageable costs lies in scale and standardization on the production side:

Common Raw Materials: Epoxy resin and fiberglass are both mature, bulk commodities with low production costs.

Scaled Production: Huge production volumes dilute production costs.

Intense Competition: Numerous suppliers, transparent pricing, and robust competition.

Comparing FR4 with other insulation materials further highlights its cost-performance advantage:

| Material Category | Cost Level | Performance Shortcomings / Applicable Scenarios | Comparison with FR4 |

| Bakelite, PPO | Lower than FR4 | Poor heat resistance, low mechanical strength (Bakelite contains formaldehyde, insufficient environmental friendliness) | Lower cost but far inferior in performance; only suitable for low-demand scenarios |

| Polyimide, PTFE, PEEK | Higher than FR4 | Excellent performance (high temperature resistance, high frequency with low loss), but expensive | Superior performance but higher cost; only used in special requirement scenarios, performance excessive for general transformers |

In actual procurement, the specific cost of FR4 is affected by the following factors. Costs can be controlled through appropriate selection:

Sheet Thickness: The thicker the sheet, the higher the cost per unit area. Select an appropriate thickness based on insulation requirements to avoid overdesign.

Performance Level: Specialized FR4 specifications, such as high Tg (e.g., Tg170), halogen-free, and high-frequency low-loss, are more expensive than standard FR4 due to their complex production processes.

Purchase Scale and Form: Large-volume purchases can yield lower unit prices. Directly purchasing standard-sized sheets and in-house processing can be less expensive than custom-molded insulation components.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……