When discussing transformers, the first things that often come to mind are their electromagnetic performance, energy efficiency, and heat dissipation. However, one crucial aspect that is often overlooked is mechanical strength. During operation, transformers are subjected to enormous electromagnetic forces, vibrations, and thermal stresses, especially under fault conditions such as short circuits. The windings must be firmly supported and secured, as even minor displacement or deformation can lead to insulation failure and potentially catastrophic faults. It is in this domain that epoxy FR4 yellow sheet demonstrates its irreplaceable value.

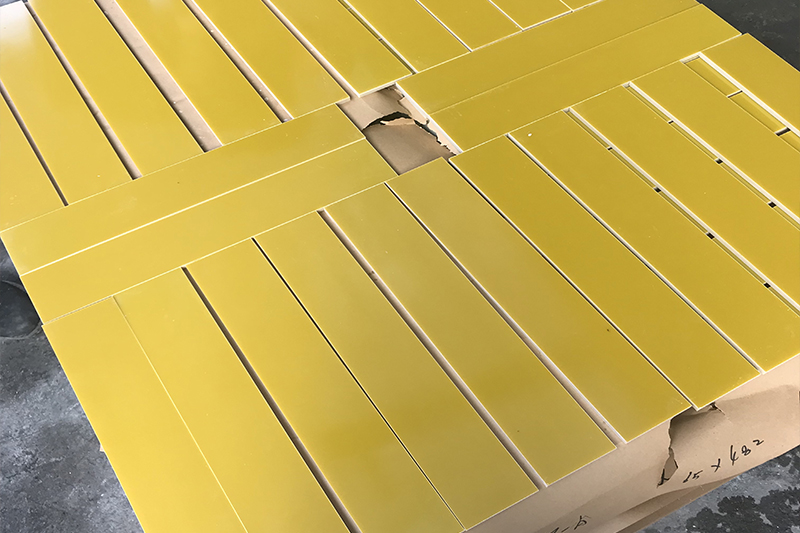

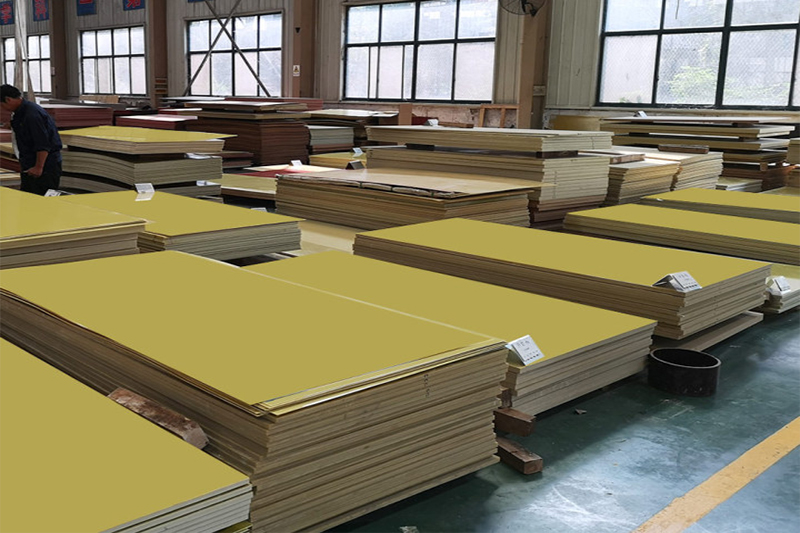

FR4 is a laminated sheet made by impregnating electronic-grade glass fiber fabric with epoxy resin, followed by high-temperature, high-pressure thermosetting. The “FR” in its name stands for Flame Retardant, meeting the UL94 V-0 flammability rating and providing a fundamental guarantee of electrical safety. Epoxy FR4 combines the mechanical strength of glass fiber with the excellent insulation and adhesion properties of epoxy resin, making it a highly versatile material for insulation structures.

The mechanical strength of epoxy FR4 yellow sheet is the core reason it is an ideal choice for transformer cores and spacer blocks. Its advantages are mainly reflected in the following aspects:

High flexural strength: FR4 has excellent bending resistance, allowing it to serve as the support framework for windings. It can withstand the enormous radial pressures generated by multilayer winding and the various mechanical stresses during subsequent processing, preventing deformation.

High compressive strength: Spacer blocks are required to axially fix the windings in a transformer. Epoxy FR4 yellow sheet blocks effectively resist the expansion and contraction of the windings, especially the huge electromagnetic forces generated during short-circuit events, preventing loosening or misalignment.

Epoxy FR4 yellow sheet has a low coefficient of thermal expansion, meaning its dimensional changes are minimal across the transformer’s temperature range, from cold to operational hot states (−50°C to +130°C or even higher). This stability ensures the reliability of the support structure, avoids loosening or stress concentration due to thermal expansion and contraction, and protects the fragile enamel insulation of the windings.

Although rigid, the epoxy resin gives the material a certain degree of toughness, allowing it to absorb and dissipate sudden impact energy. This prevents brittle fracture during transportation, installation, or fault conditions.

Transformers are subjected to continuous electromagnetic vibrations from the power grid throughout their lifecycle. Epoxy FR4 yellow sheet can endure these alternating stresses over the long term without fatigue cracking or strength degradation, ensuring long-term mechanical integrity.

During a short circuit, enormous currents flow instantaneously through the windings, generating electromagnetic forces much greater than during normal operation. Strong mechanical support serves as the first line of defense to prevent winding deformation, collapse, or damage. Epoxy FR4 yellow sheet components play a critical role in this scenario.

A rigid mechanical structure effectively reduces the vibration amplitude of the core and windings, thereby lowering operational noise and minimizing material wear caused by long-term vibration.

Mechanical displacement is one of the main causes of insulation failure. By maintaining precise spacing and positioning between windings, epoxy FR4 yellow sheet indirectly preserves the dielectric strength of oil gaps or air gaps, preventing partial discharge and breakdown.

A transformer with a mechanically stable structure experiences slower aging of internal components, significantly extending service life while reducing maintenance costs and downtime.

Its mechanical strength, rigidity, and dimensional stability directly affect the transformer’s ability to withstand short-circuit forces, vibration, and thermal stress. As such, it is a key material for ensuring long-term reliable operation. Paying attention to the mechanical performance of this material is practically significant for enhancing the overall performance of transformers.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……