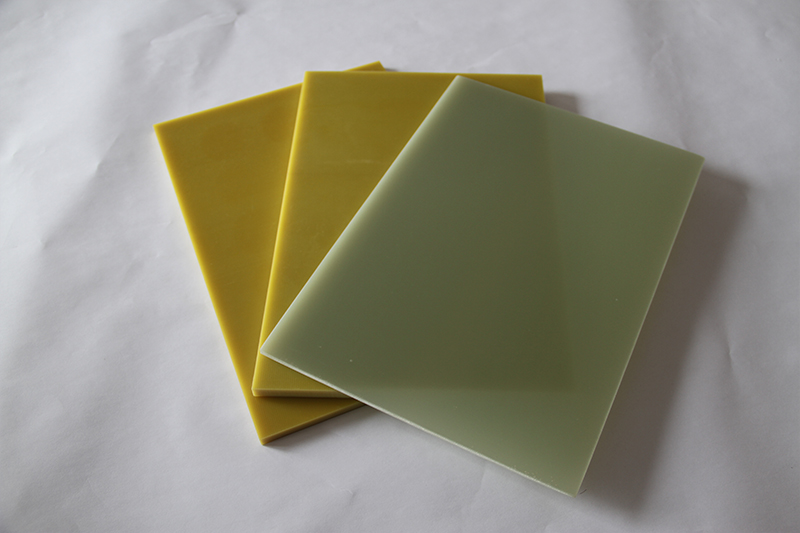

In the field of electronic materials, epoxy FR4 yellow sheets and green FR4 sheets are often mentioned, and many people wonder about the differences between them. In fact, the core distinction between these two types of boards does not come from the substrate itself, but rather from the color of the solder mask coating applied to the surface. Structurally, their core (substrate) is almost identical — both are FR4 composite materials made by impregnating fiberglass cloth with epoxy resin and then curing it under heat and pressure.

Whether it is yellow FR4 or green FR4, the internal substrate is uniformly FR4. To fully understand FR4, it helps to break down its name:

FR: It is short for “Flame Retardant,” highlighting the material’s essential fire-resistant property for electronic applications.

4: It refers to a specific material grade, representing an industry-standard classification for this type of composite.

The production of FR4 substrate follows strict standards: Electronic-grade fiberglass cloth serves as the reinforcing skeleton, which is thoroughly impregnated with epoxy resin adhesive. It is then cured under high temperature and pressure to form a laminate. This structure endows FR4 with excellent comprehensive properties — outstanding mechanical strength to withstand physical stress, reliable electrical insulation to ensure circuit safety, as well as sufficient heat resistance and flame retardancy to meet the requirements of electronic devices. As a result, FR4 has become the ideal material for manufacturing printed circuit boards (PCBs) and insulating spacers.

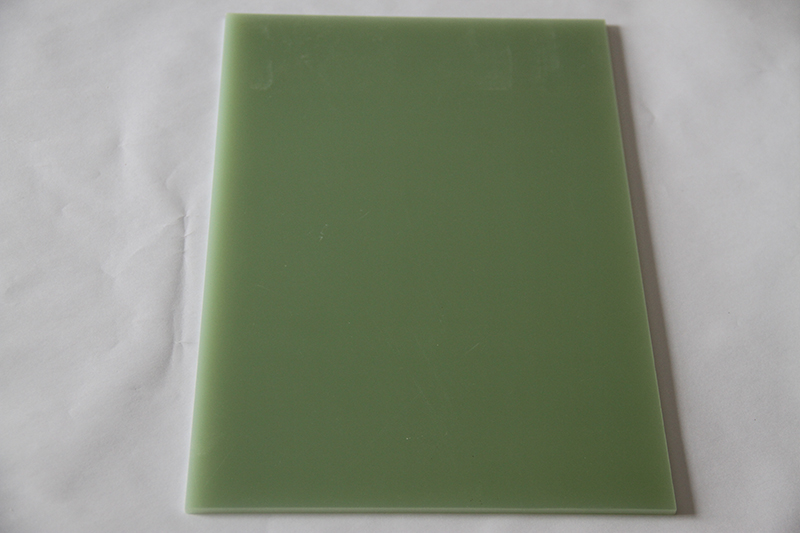

It is important to note that the intrinsic color of FR4 substrate is not the same as the final visible board color. The natural appearance is usually a translucent light yellow or light green. The board’s final appearance is determined by the solder mask coating applied afterward.

The difference in color between yellow FR4 sheets and green FR4 sheets lies in the final stage of production, where a permanent protective coating — the solder mask — is applied. The manufacturing process itself is identical, with only differences in the color selection of solder mask:

1.Green FR4 Epoxy Board: After the copper circuitry is patterned on the substrate, a green solder mask is applied to the board’s surface. Through exposure and development, the solder mask is precisely opened to expose component pads that require soldering. Finally, the board is cured, resulting in a stable green finish. Green solder mask has been the electronics industry standard for decades and remains the mainstream choice today.

2.Yellow FR4 Epoxy Board: The production process is exactly the same as that of the green sheet. The only difference is that the green solder mask ink is replaced with yellow solder mask ink, resulting in a yellow board appearance in the end.

Although yellow and green FR4 boards are functionally identical, green solder mask accounts for 99% of the market share due to a combination of historical, practical, and ergonomic factors:

1.Higher Contrast: Against a green solder mask background, the white silkscreen markings (such as reference designators and labels) and the silver-colored solder pads stand out sharply. This enhances visibility for both human inspectors on the production line and automated optical inspection (AOI) systems, reducing error rates and improving efficiency in assembly, soldering, and repair.

2.History and Economies of Scale: Green solder mask has been widely adopted as the industry standard for decades. Its large-scale production reduces raw material and manufacturing costs, while also ensuring a mature and stable supply chain with abundant availability and reliable delivery. This further reinforces its dominant position in the market.

3.Visual Comfort: From an ergonomic perspective, green is less straining on the human eye. In electronics manufacturing environments where workers must perform prolonged visual inspections of circuit boards, green sheets help reduce eye fatigue and improve working comfort.

Although green FR4 sheets dominate the market, yellow FR4 sheets also have specific application scenarios:

1.Teaching and Laboratory Use: Yellow sheets are often seen in university electronics labs. Since copper contrasts less sharply with yellow than with green, yellow FR4 epoxy boards make copper traces more visually distinguishable, helping students better understand and study PCB layouts.

2.Brand Identity: Some companies, especially those producing high-end products such as graphics cards or development boards, choose yellow or other special solder mask colors to differentiate their products. Unique board colors help shape brand identity and attract consumer attention.

3.Special Requirements: In niche applications where appearance customization is valued, or based on specific customer preferences, yellow FR4 sheets may be selected.

In simple terms, the essential difference between yellow and green FR4 sheets can be summarized as:

Yellow FR4 Sheet = Standard FR4 Substrate + Yellow Solder Mask (Protective Coating)

Green FR4 Sheet = Standard FR4 Substrate + Green Solder Mask (Protective Coating)

The core performance of the two is identical, and color does not affect their electrical, thermal, or mechanical properties. When making a choice, there is no need to worry about performance issues. The following dimensions can mainly be considered:

· For conventional electronic device manufacturing, where cost-effectiveness and compatibility are the priority, green FR4 boards are the default choice, supported by a mature supply chain and lower production costs.

· For educational purposes, product differentiation, or customized aesthetics, yellow FR4 sheets can be chosen according to the specific scenario.

Both yellow and green FR4 sheets fully meet the fundamental requirements of electronic applications. The decision mainly depends on matching the sheet color to the intended use and preference.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……