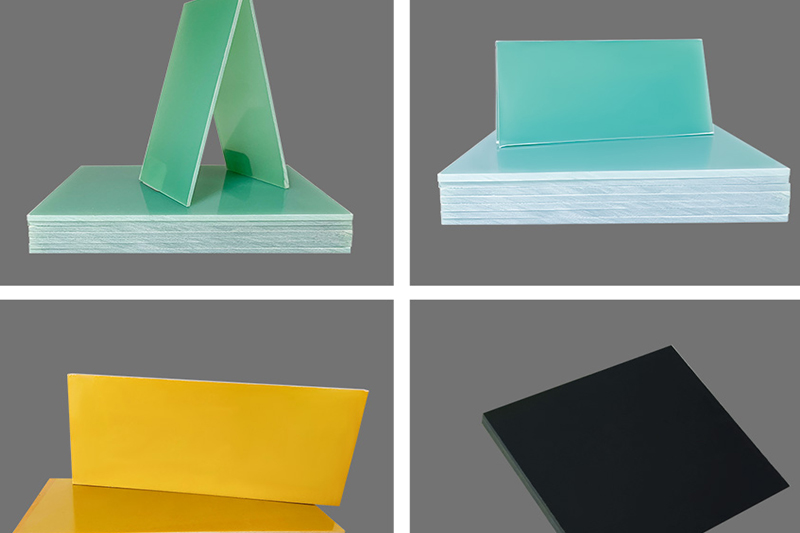

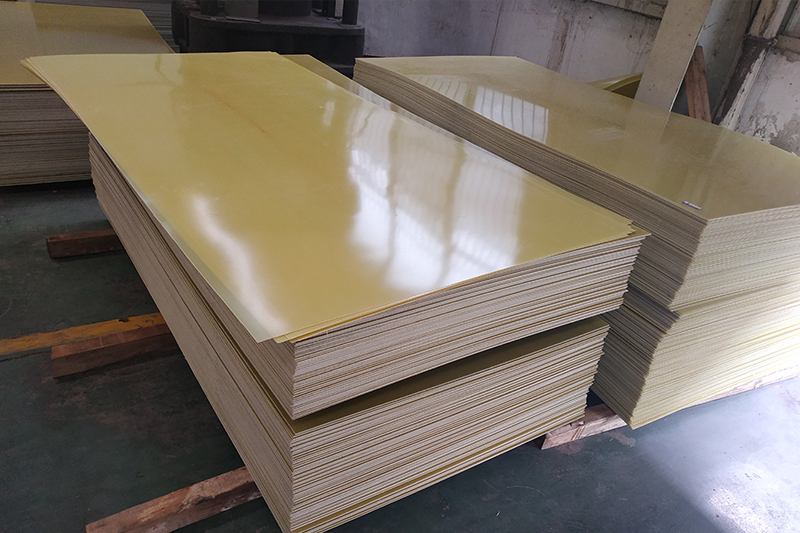

In fields such as electronics, electrical engineering, and new energy, FR4 epoxy sheet is a widely used composite material. Reinforced with fiberglass cloth and using epoxy resin as its matrix, FR4 stands out for its excellent mechanical properties, reliable electrical insulation, and easy machinability, making it a core substrate for many products. Among its performance parameters, thermal conductivity—an essential metric for evaluating a material’s heat transfer capability—directly determines the thermal management design approach and applicable usage scenarios.

One of the most notable thermal characteristics of FR4 epoxy sheets is their extremely low thermal conductivity, typically in the range of 0.2 – 0.4 W/(m·K). The contrast becomes more striking when compared to common metals: copper has a thermal conductivity of about 400 W/(m·K), while aluminum is around 200 W/(m·K). This means FR4’s heat conduction ability is nearly three orders of magnitude lower than that of these metals—explaining why FR4-based circuit boards often face challenges in heat dissipation.

Thermal conductivity (commonly denoted as λ or k, unit: W/(m·K)) is a key physical parameter that describes a material’s ability to conduct heat. A higher value indicates stronger thermal conduction, meaning heat can transfer through the material more quickly.

As a composite material, the thermal conductivity of FR4 epoxy sheets is determined by both their primary constituents and internal structure. This can be analyzed from three perspectives:

Epoxy resin is a polymer with a disordered molecular structure. During heat transfer, phonons—the main carriers of thermal energy—are heavily scattered within this disordered structure, making it difficult for heat to pass through efficiently. As a result, epoxy resin itself has extremely poor thermal conductivity, with a value of only about 0.2 W/(m·K).

The reinforcing material, electronic-grade fiberglass cloth (E-glass), also has a relatively low thermal conductivity, typically around 1.0 – 1.3 W/(m·K). Although this is slightly higher than epoxy resin, it is still considered a low-conductivity material, offering only limited improvement to the overall thermal performance.

Inside FR4 epoxy sheets, numerous interfaces exist between epoxy resin and fiberglass. These interfaces introduce significant resistance to heat transfer, further weakening the material’s overall ability to conduct heat.

In summary,the bulk of FR4’s volume is filled with epoxy resin, which has extremely poor thermal conductivity. The contribution of fiberglass to thermal conduction is minimal, and the presence of numerous interfaces creates substantial thermal resistance. Collectively, these factors keep the overall thermal conductivity of FR4 epoxy sheets at a consistently low level.

Although 0.2 – 0.4 W/(m·K) is the typical thermal conductivity range for FR4 epoxy sheets, in practical applications the actual value can vary depending on several factors:

The thermal conductivity is negatively correlated with the epoxy resin content in the sheet. Higher resin content generally leads to lower thermal conductivity. While resin-rich boards tend to offer greater flexibility, their heat dissipation capability is correspondingly reduced.

Different weave styles (such as plain weave or twill) and thicknesses of fiberglass cloth (common types include 106, 1080, 2116, 7628, etc.) affect how epoxy resin impregnates the cloth and the orientation of fibers. These variations can cause subtle but noticeable differences in the thermal conductivity of the board.

It is important to note that thermal conductivity is an intrinsic property of the material and does not depend on board thickness. However, thermal resistance (R) is proportional to thickness, calculated as: R = L/(λ×A)

where L is thickness, λ is thermal conductivity, and A is the cross-sectional area. Thus, thicker FR4 epoxy sheets result in higher thermal resistance, making heat transfer more difficult and heat dissipation more challenging.

While the thermal conductivity of materials fluctuates with temperature, in the typical operating temperature range of electronic devices, the variation in FR4 epoxy sheets is relatively small and has limited practical impact.

According to the thermal management requirements of different scenarios, the selection of FR4 epoxy sheets should follow a “demand-oriented” principle. It can generally be divided into three categories:

Core Requirement: Meet basic heat dissipation needs while maintaining strict cost control (high cost sensitivity).

Selection Approach: Use standard FR4 epoxy sheets, and enhance thermal performance through PCB design optimizations such as increasing copper foil area or improving trace layout to aid heat dissipation.

Core Requirement: Balance thermal conductivity and cost while ensuring electrical insulation, and avoid localized overheating caused by heat accumulation.

Selection Approach: Use alumina-filled FR4 epoxy sheets. The addition of alumina improves thermal conductivity to some extent. Reducing the thickness of thermal resistance layers can further optimize overall heat dissipation efficiency.

Core Requirement: Rapidly dissipate the large amounts of heat generated during operation, prevent electronic components from failing due to excessive temperature, and ensure long-term stable performance.

Selection Approaches:

Option 1: Use boron nitride-filled FR4 epoxy sheets. Boron nitride offers excellent thermal conductivity, significantly enhancing the overall heat transfer capability of the sheet.

Option 2: Select metal-based composite FR4 sheets (e.g., aluminum substrate + FR4 insulation layer). The combination of the high thermal conductivity of the metal substrate with the insulation of FR4 enables both efficient heat dissipation and reliable electrical insulation.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……