G10, a composite material made of glass fiber cloth and epoxy resin under high temperature and high pressure, plays an irreplaceable role in multiple industrial fields thanks to its outstanding mechanical properties, insulation properties, and corrosion resistance. The following details the main applications and core advantages of G10 machined parts.

In power equipment such as high-voltage switches and transformers, G10 machined parts are often used to manufacture core insulation components such as insulators and separators. With excellent arc resistance and anti-breakdown properties, they provide reliable protection for stable equipment operation. Compared with traditional ceramic materials, G10 is lighter and easier to process, significantly reducing production and installation costs.

In precision structures such as electronic equipment housings and brackets, G10 material can achieve precise molding of complex shapes through CNC machining technology, perfectly meeting the dual requirements of lightweight and high strength. For example, in the manufacture of drone fuselage frames, the use of G10 machined parts can not only effectively reduce the weight of the fuselage and improve endurance, but also maintain excellent impact resistance to ensure safe equipment operation.

G10 material’s excellent wear resistance makes it an ideal choice for low-speed, heavy-load gears. It is widely used in transmission systems for agricultural machinery, textile equipment, and more. Compared to traditional metal gears, G10 gears operate with lower noise and require no additional lubrication, significantly reducing equipment maintenance frequency and costs.

In chemical pumps, valves, and other fluid-transporting equipment, gaskets made from G10 withstand corrosive media like acids and alkalis, while also exhibiting excellent high-temperature resistance. Their sealing effectiveness far exceeds that of ordinary rubber gaskets, significantly extending their service life and effectively reducing the risk of equipment leaks and the frequency of replacement.

G10 material offers excellent machinability, supports high-speed cutting processes, and produces a highly smooth finished surface, meeting the manufacturing requirements of high-precision parts. Combined with CNC machining center programming commands (such as the G10 coordinate system setting function), it enables rapid changeovers for multiple batches of workpieces, significantly improving the efficiency and accuracy of mass production.

G10 material (especially graphite-filled grades) offers both wear resistance and self-lubricating properties, making it ideal for robot joint bearings and other moving parts. Using G10 parts can reduce frictional losses during joint operation, lower equipment failure rates, extend maintenance cycles, and enhance the robot’s operational stability and service life.

Compared to metal materials, G10 is lighter and offers excellent insulation and corrosion resistance, adapting to diverse operating environments. Compared to ordinary plastics, G10 offers advantages in key properties such as strength and temperature resistance, enabling it to handle more complex working conditions.

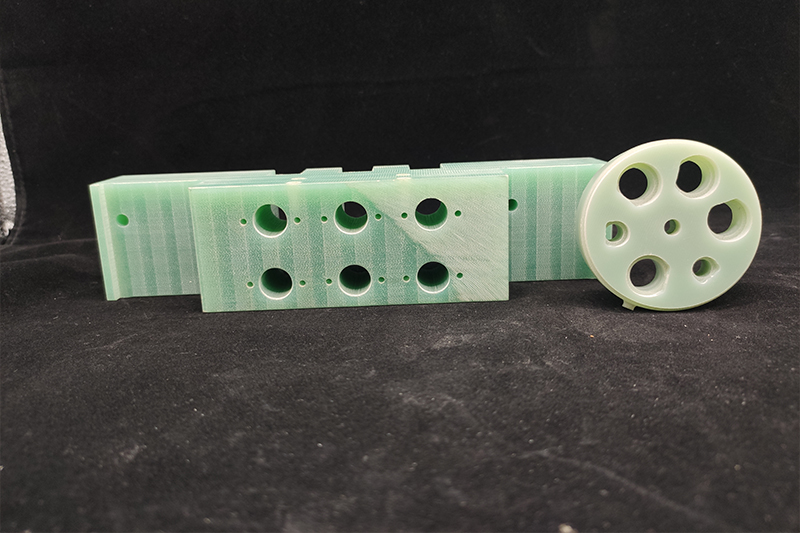

G10 can be manufactured into complex parts through various processes, including CNC machining, drilling, and milling. Its high processing flexibility makes it particularly suitable for small-batch, multi-specification customized production, enabling rapid response to diverse market orders.

G10 machined parts, with their dual advantages in performance and processing, are increasingly being used in electronics, mechanical manufacturing, industrial automation, and other fields. With the continuous advancement of industrial technology, the performance of G10 material will continue to improve, and its application scenarios will continue to expand, providing strong support for equipment upgrades and efficiency improvements across various industries.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……