FR4 epoxy sheet, with its excellent electrical properties, mechanical strength, and corrosion resistance, has been widely used in numerous fields, including electronics, electrical engineering, and chemical engineering. As a composite material, its performance stability and service life are of great concern. So, what is the shelf life of FR4 epoxy board? How long can it actually last in use? This article will answer these questions in detail.

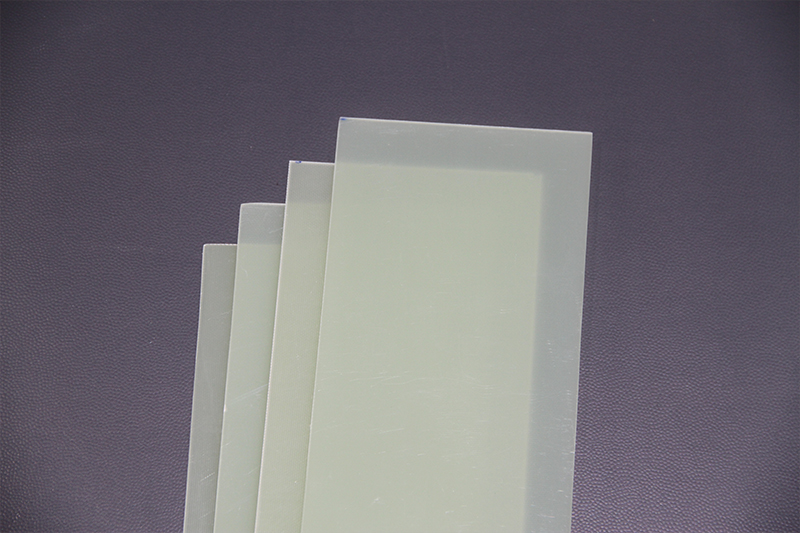

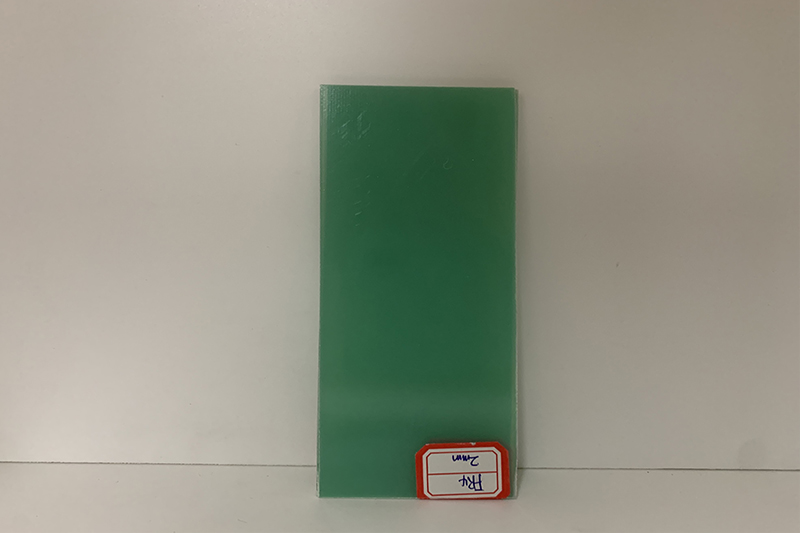

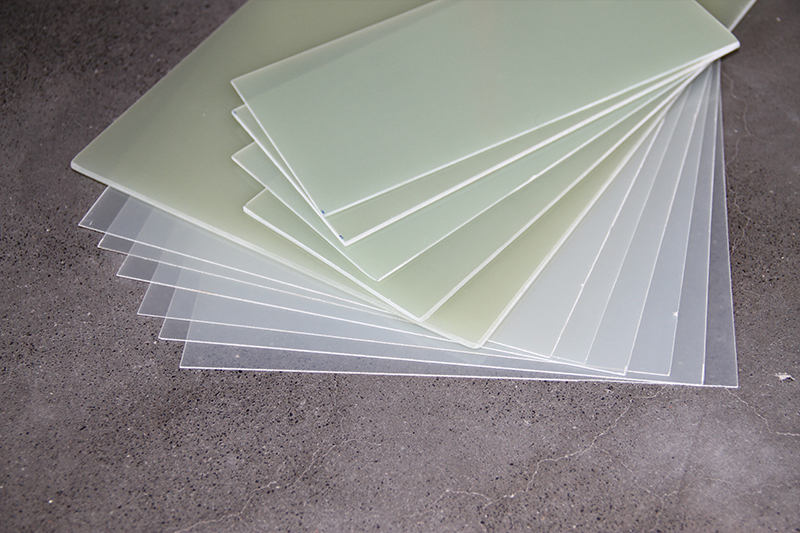

FR4 epoxy sheet is an insulating material made from epoxy resin and glass fiber through a special composite process. Its core advantages include:

Excellent insulation properties, effectively blocking current conduction;

Good high-temperature resistance, adapting to a range of temperature fluctuations;

Strong mechanical strength, capable of withstanding certain structural stresses;

Excellent corrosion resistance, resistant to a variety of chemicals.

These properties enable stable operation in complex environments, but material properties are not permanent. Over time and due to environmental influences, FR4 epoxy sheet may degrade, making shelf life and service life key considerations.

Shelf life primarily refers to the guaranteed performance period of the material when it is not in use and properly stored. Its duration is directly affected by the following factors:

The storage environment is a key factor in determining shelf life. FR4 epoxy boards must be stored indoors in a dry, ventilated, and light-proof environment, away from sources of fire, corrosive substances, and strong mechanical impact.

If the storage environment is humid, the material will absorb moisture, resulting in a decrease in insulation performance.

Direct sunlight or high temperatures will accelerate resin aging.

Contact with corrosive gases may cause chemical corrosion, shortening the shelf life.

The quality of the raw materials and the production process directly affect the stability of epoxy boards.

High-quality products use high-purity epoxy resin and continuous glass fiber, and are produced under strict process control, resulting in a more stable molecular structure and a longer shelf life.

Inferior products may suffer from impurities in the raw materials and rough workmanship, resulting in inherent performance deficiencies and a significantly shorter shelf life.

Under ideal storage conditions (unopened, ambient humidity ≤ 60%, temperature 20-30°C, and no corrosive gases), FR4 epoxy sheet typically has a shelf life of three years. During this period, core specifications such as the material’s insulation performance and mechanical strength should remain within factory standards.

If the storage environment does not meet requirements, the shelf life can be significantly shortened:

Excessive humidity (>70%) or extreme temperature fluctuations (>40°C or <0°C) can shorten the shelf life to one to two years.

Prolonged exposure to direct sunlight or corrosive environments can cause material performance degradation within one year, such as surface cracking and decreased insulation resistance.

The service life refers to the period of time the material maintains stable performance under normal operating conditions after being put into use. This duration far exceeds the shelf life and is primarily affected by the operating environment and working conditions.

In a standard operating environment (meeting the material’s rated parameters), FR4 epoxy board typically has a service life of over 10 years. This is due to its:

Stable insulation properties, allowing it to withstand rated voltage for long periods of time;

High strength and high modulus, maintaining structural integrity;

Excellent moisture and high temperature resistance, adapting to normal environmental fluctuations.

Humidity: High humidity environments (such as humid workshops or outdoor areas) cause the material to slowly absorb moisture, potentially reducing insulation resistance and mechanical strength. Sealing and regular drying are necessary to extend service life.

Temperature: Prolonged exposure to high temperatures (exceeding the material’s rated temperature resistance, typically 130°C for FR4) accelerates resin aging, causing the material to become brittle and performance degradation. Excessively low temperatures can reduce the material’s toughness and make it susceptible to mechanical damage.

Corrosive Gases: In environments with acidic or alkaline gases or salt spray, such as chemical workshops or at the seaside, the material may be chemically corroded, resulting in blistering and delamination on the surface. Therefore, it is necessary to select reinforced anti-corrosion epoxy panels or add an isolation layer.

Electrical Load: If the actual voltage or current exceeds the rated value, it may cause local overheating of the material, accelerating aging, or even causing breakdown. Strictly adhere to design parameters and avoid overloading.

Mechanical Stress: Long-term exposure to vibration, shock, or continuous structural stress (such as frequent equipment startup and shutdown, or heavy objects pressing against it) may cause fatigue damage, cracking, or fracture. Optimize the mounting structure, select a high-toughness model, or add a buffer design.

To ensure stable material performance, it is recommended to strictly control the environment from the storage stage, avoid extreme conditions during use, and conduct regular performance testing to maximize its value.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……