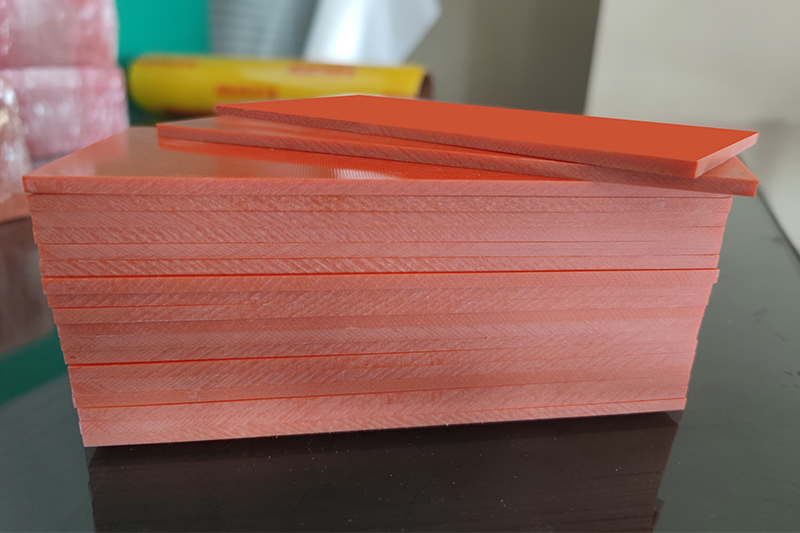

Bakelite, also known as phenolic laminate, is a composite board made from high-quality bleached wood pulp and linter paper as a reinforcing base, and a phenolic resin derived from a reaction of high-purity synthetic petrochemical raw materials as a binder. This board is laminated and classified as a thermoset plastic product. Its excellent insulation, antistatic properties, wear resistance, and high-temperature resistance make it widely used in applications such as insulating switches, variable resistor substrates, mechanical mold manufacturing, and production line jigs for electronic products. It can even operate reliably in harsh environments such as transformer oil.

Bakelite boasts high insulation resistance and excellent arc resistance, effectively blocking current conduction. It is an ideal choice for electronic component substrates, electrical switch panels, and insulating gaskets, ensuring the safe and stable operation of electrical equipment.

Advantages: Bakelite offers high hardness and surface wear resistance, and can withstand a certain degree of mechanical friction and pressure, making it suitable for components requiring structural strength.

Disadvantages: The material is brittle and has low impact resistance, making it prone to cracking during severe collisions or processing.

Improvements: Manufacturers can improve the overall toughness and mechanical properties of the bakelite by adding a cotton layer.

The long-term operating temperature range of bakelite is approximately 120-140°C. It can withstand short-term high temperatures exceeding 150°C. However, carbonization may occur after exceeding this temperature limit, resulting in performance degradation. Therefore, it is important to avoid prolonged exposure to excessive temperatures.

Bakelite exhibits a certain degree of corrosion resistance to weak acids, weak bases, and common organic solvents. However, it is susceptible to chemical corrosion in strong acidic or alkaline environments or in prolonged exposure to moisture, leading to structural degradation and performance degradation.

Bakelite is easily machined for drilling, cutting, and grinding, making it suitable for the production of complex shapes. However, operators must ensure proper cooling during processing to avoid localized overheating that can cause delamination and cracking of the sheet.

Under normal operating conditions, bakelite typically has a service life of 3-5 years. This life cycle is closely related to its inherent properties of “non-water absorption, non-conductivity and strong durability”, which enables it to play a long-lasting role in both daily life and industrial production.

The operating environment is a key factor in determining the lifespan of bakelite boards:

Ideal Environment: In a dry, well-ventilated environment free of corrosive gases, bakelite boards’ insulation properties and mechanical strength are effectively maintained, aging is slow, and their service life can approach or exceed their upper limit.

Harsh Environment: If bakelite boards are exposed to humidity, high temperatures (over 140°C), or corrosive media for extended periods, they will experience accelerated aging. This manifests as decreased insulation performance, weakened mechanical strength, and surface cracking, potentially shortening their service life to less than three years.

Users should regularly observe the bakelite board surface, particularly checking for cracks, discoloration, bulging, or moisture absorption to detect early signs of aging.

For daily cleaning, wipe away dust from the bakelite board surface with a dry, soft cloth. Users should avoid using corrosive cleaners containing acids or alkalis to prevent chemical damage to the surface.

Use environments should be kept well-ventilated and dry. Avoid direct sunlight, high temperatures, or prolonged high humidity. This will slow down material aging.

In electrical applications, equipment parameters must be strictly controlled within the rated range of the bakelite to prevent overheating and material damage due to overload.

Bakelite, with its comprehensive properties of insulation, heat resistance, and high mechanical strength, is an economical and practical material for both electrical and mechanical applications. Although its lifespan is significantly affected by the environment, proper selection (e.g., choosing standard or modified types based on the environment), along with proper use and regular maintenance, can significantly extend its service life.

In high-temperature, high-humidity, or highly corrosive environments, users are advised to prioritize higher-performance alternative materials, such as epoxy board or G10 fiberglass board, to ensure long-term stability.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……