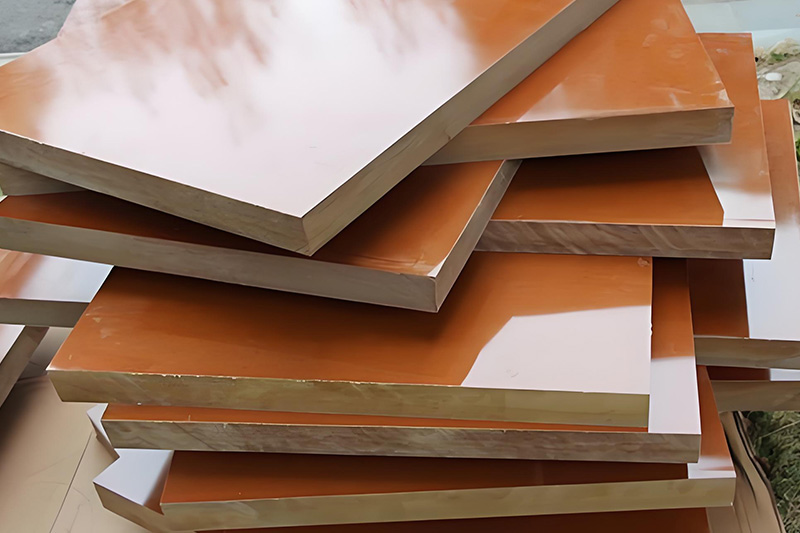

Bakelite is a commonly used insulating material in the electrical industry. Its excellent insulating properties, mechanical strength, and heat resistance make it widely used in transformers, electrical switches, motors, and other equipment. Its service life is typically 5 to 10 years, varying depending on quality, operating environment, and maintenance. High-quality products can extend this lifespan even further under reasonable conditions. This article analyzes the key factors influencing its durability from the perspectives of material properties, manufacturing process, and operating environment, to help you scientifically estimate its lifespan and optimize its usage strategy.

Bakelite is made from a paper substrate impregnated with phenolic resin and then laminated and cured under high temperature and high pressure. Its core properties determine its fundamental durability:

Mechanical Strength: The dense structure formed by the lamination process provides impact and abrasion resistance, with cloth-based products offering superior strength.

Insulating Properties: The chemical stability of phenolic resin provides excellent dielectric strength, a key component of electrical insulation.

Heat Resistance: The cured three-dimensional network structure can withstand certain temperatures, but prolonged exposure to high temperatures will accelerate aging. Hygroscopicity: Paper substrates tend to absorb moisture, and a humid environment may reduce insulation performance. This is a shortcoming that requires special attention.

The service life of bakelite is determined by multiple factors, including materials, manufacturing, and usage conditions. The following four factors require special attention:

The material formulation and substrate type directly determine fundamental performance and are the fundamental factors affecting its service life:

►Phenolic Resin Types:

Thermosetting Phenolic Resin: After curing, it forms a stable three-dimensional network structure, offering excellent heat and chemical resistance. However, it is highly brittle and prone to cracking under long-term mechanical stress.

Modified Phenolic Resin: By adding ingredients such as epoxy and silicone, it enhances toughness and impact resistance, reducing structural damage during aging and extending its service life.

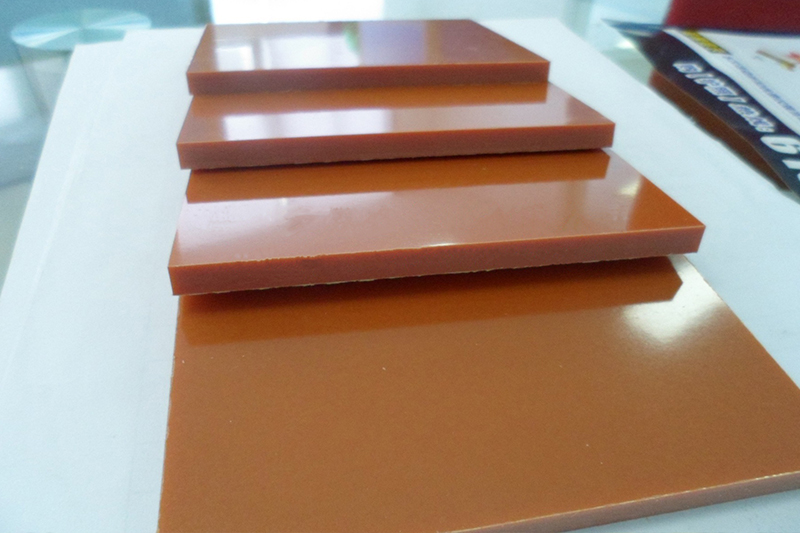

►Substrate Types:

Paper-Based: Using wood pulp paper as the substrate, it is low-cost but highly hygroscopic, making it suitable for dry, low-load applications (such as internal insulation components in home appliances).

Cloth-Based: Using cotton or glass cloth as a reinforcement layer, it offers superior mechanical strength, temperature resistance, and moisture resistance, making it suitable for high-load, high-vibration applications (such as motor slot wedges and transformer insulation pads).

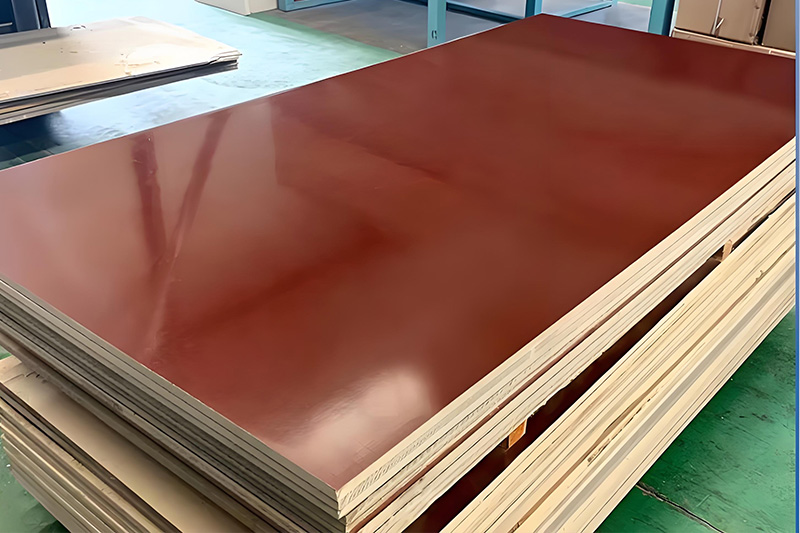

Manufacturing process precision directly impacts actual lifespan, and process defects can accelerate aging:

Lamination process: High-temperature, high-pressure parameter control can reduce air bubbles and voids between layers, improve density, and reduce water absorption. Poor process performance can easily lead to delamination and voids between layers, exacerbating partial discharge and accelerating water infiltration, leading to corrosion or insulation breakdown.

Surface treatment: Coating with conformal coating (moisture-proof, mildew-proof, and salt spray-proof) or impregnation with insulating varnish creates a surface protective barrier, enhancing resistance to moisture, salt spray, and other environmental conditions, and reducing environmental corrosion on the internal structure.

Environmental factors directly affect the aging rate, and harsh environments can shorten the effective lifespan:

Temperature: Long-term high temperatures (exceeding the rated temperature) can accelerate resin degradation and embrittlement, reducing mechanical strength and insulation performance. Short-term overload and high temperatures must be controlled within the allowable range to avoid cumulative damage.

Humidity: Hygroscopicity increases with increasing humidity, and after moisture absorption, dielectric strength decreases, which can easily cause creepage, flashover, or breakdown. Humid environments require sealing designs, desiccants, or the use of low-hygroscopic cloth-based products.

Chemical Corrosion: Acids, alkalis, and solvents can damage the phenolic resin structure, causing expansion, cracking, and loss of strength. Corrosion-resistant modified formulations should be used when exposed to chemical media.

Mechanical Stress: Frequent vibration, impact, or prolonged load-bearing can cause internal microcracks to propagate, ultimately leading to structural failure. This can be alleviated by optimizing the equipment structure (such as adding buffers) or using high-toughness cloth-based products.

The degree of electrical load matching directly affects the rate of insulation aging. Improper loading can accelerate failure:

Voltage Level: Prolonged overvoltage can subject the insulation to electric field strength exceeding the design, accelerating molecular chain breakage and shortening the aging cycle. When selecting insulation, allow a margin of 1.2-1.5 times the rated voltage to avoid prolonged overvoltage operation.

Partial Discharge: Areas of concentrated electric fields (such as corners and gaps) are prone to partial discharge. Energy accumulation can carbonize the surface and form conductive pathways, ultimately leading to insulation failure. Optimizing the electric field distribution through chamfering or spraying a conductive coating can suppress discharge and delay aging.

A scientific understanding of the characteristics and influencing factors of bakelite boards can accurately determine their lifespan and maximize performance through reasonable selection and maintenance, ensuring the stable operation of electrical equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……