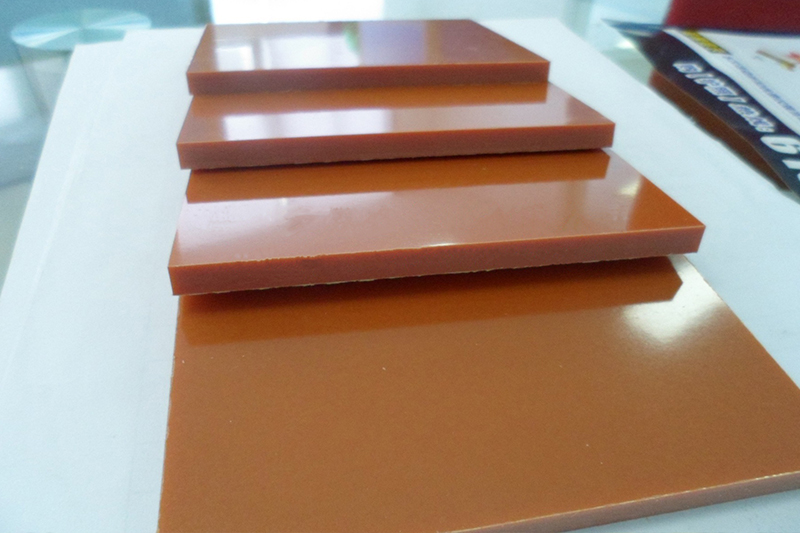

Bakelite, also known as phenolic laminate, is an indispensable insulating material in the electrical industry. Typically available in red, orange, and black, it is a common type of laminate and, due to its excellent electrical and physical properties, has become one of the most widely used and consumed industrial laminates worldwide. Its manufacturing process rigorously selects high-quality bleached wood-based paper and cotton linter paper as reinforcing materials, and uses phenolic resin derived from high-purity, fully synthetic petrochemical raw materials as a binder, ensuring the material’s superior performance and consistent quality from the source.

The core function of bakelite is to isolate conductive components in a circuit. Through physical insulation, it blocks abnormal current flow, effectively preventing safety hazards such as short circuits and leakage, and providing a fundamental guarantee for the stable operation of electrical equipment.

Due to its outstanding comprehensive performance, Bakelite is widely used in the following electrical applications:

High-voltage electrical appliances: Such as insulating separators and support components;

Switchboards: Used in the manufacture of core components such as insulating switches and contact bases;

Motors and wires and cables: Used as insulation layers and internal structural supports;

Electrical equipment maintenance: Used as temporary or permanent insulation components for insulation defect detection and equipment repair.

Currently, the mainstream types of bakelite on the market include thermoset impregnated paperboard and phenolic impregnated paperboard, which share many common advantages:

Thermoset impregnated paperboard: It is resistant to water, oil, acids, and alkalis, and has stable insulation properties. It is commonly used in applications such as electrical equipment casings and insulating gaskets.

Phenolic impregnated paperboard: It has high mechanical strength and excellent high-temperature resistance, making it suitable for manufacturing core components such as high-voltage switchgear and motor insulation structures.

All types of bakelite offer excellent insulation, stable mechanical properties, and good chemical resistance, making them suitable for use in complex electrical environments.

At room temperature, Bakelite exhibits high insulation resistance and excellent dielectric strength, effectively blocking current conduction. This makes it an ideal material for key components such as insulated switches, varistors, and insulating separators, fundamentally ensuring the safety of electrical equipment.

Bakelite is static-free, preventing sparks or interference caused by static buildup during operation and use. It is particularly suitable for the manufacturing of static-sensitive electrical accessories, enhancing product stability.

High-temperature resistance: Maintains stable performance within a certain temperature range, adapting to the heat release environment of electrical equipment operation.

Wear Resistance: High surface hardness prevents frictional wear and tear over long-term use, extending the life of the accessory.

After heat curing, Bakelite forms an irreversibly stable structure that cannot be reshaped, resulting in high mechanical strength and strong resistance to deformation. Furthermore, its specific gravity remains stable at 1.45, and its warpage is controlled within 3%, meeting the dimensional requirements of precision electrical accessories.

Bakelite is easy to cut, drill, and polish, enabling the manufacture of complex electrical components to meet the structural requirements of diverse equipment.

In summary, Bakelite, with its excellent insulation, safety, environmental resistance, and machinability, has become a core material for the manufacture of electrical components, supporting the stable operation of high-voltage electrical equipment, switchgear, motors, and other applications.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……