The performance of insulation paperboard directly determines its operational stability and safety. High-quality insulation paperboard not only ensures long-term, stable operation of equipment but also provides excellent insulation protection in complex environments. So, how do you determine whether insulation paperboard meets quality standards? The following provides a detailed analysis based on core performance indicators, manufacturing processes, and other dimensions.

Flammability is a core safety indicator for insulation paperboard. High-quality products should exhibit strong flame retardancy when exposed to flames or quickly self-extinguish after being removed from the fire source, preventing the spread of flames and potential safety accidents. This characteristic is particularly important in high-temperature, high-risk industrial environments, directly impacting the safety of equipment and operators.

The core function of insulation materials is to isolate electrical current. Therefore, two indicators, insulation resistance and resistivity, are important to consider:

Insulation resistance is inversely proportional to the material’s conductivity. Higher resistance values indicate lower conductivity risks.

Resistivity represents the electrical resistance per unit volume. For insulation paperboard, higher resistivity indicates a stronger ability to block the flow of current and more reliable insulation performance.

Tensile strength: As a key indicator for evaluating the mechanical properties of insulating materials, tensile strength measures the maximum stress a material can withstand during stretching. High-quality insulating paperboard should possess excellent tensile strength to ensure it resists breakage and fracture during installation and use, maintaining its structural integrity.

Arc resistance: During operation of electrical equipment, arcs may form on the surface of insulating paperboard due to partial discharge. High-quality products must withstand arcing under specified test conditions (using AC high-voltage, low-current to simulate arcing) without forming a conductive layer. The longer this withstands, the greater the arc resistance, effectively preventing insulation failure caused by arc breakdown.

The performance advantages of high-quality insulating paperboard are largely due to its rigorous scientific manufacturing process. Taking high-performance insulating paperboard as an example, its typical production process is as follows:

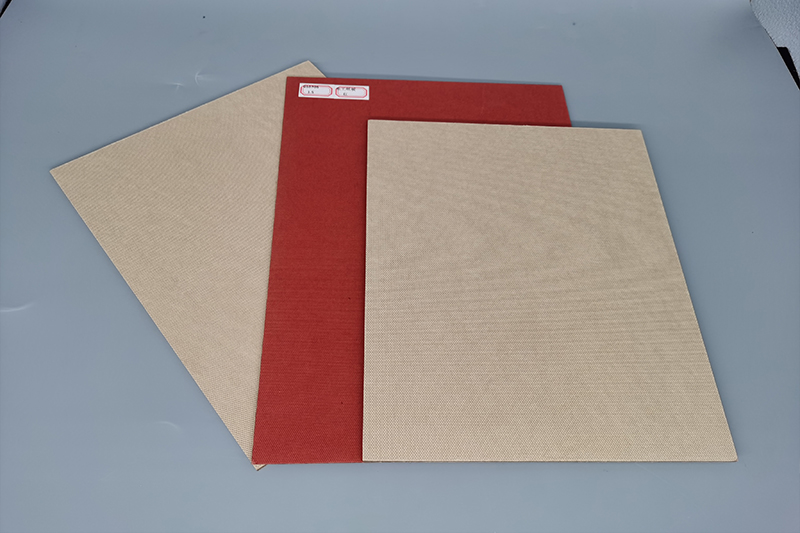

Material Selection: A reinforced base material of alkali-free glass fiber cloth specifically for electrical applications is used to ensure basic mechanical properties and insulation stability.

Bonding and Forming: High-temperature silicone resin is used as the adhesive. Through multiple processes including high-temperature baking, drying, and pressing, the insulation material is finally formed into a roll.

Finished Product Characteristics: A high-quality finished product should be dry and free of adhesion, while also exhibiting excellent bending flexibility for easy installation. Furthermore, through process optimization, product thickness uniformity is improved, and the single-layer voltage breakdown resistance is enhanced, thereby achieving both improved tensile strength and electrical insulation performance.

High-quality insulation paperboard must be adaptable to specific environmental requirements. For example, insulation paperboard produced using the aforementioned process, due to its combination of high-temperature resistance (suitable for high-temperature operating conditions) and high insulation performance, is particularly suitable for high-temperature equipment such as industrial electric furnaces and power-frequency furnaces in the steel and metallurgical industries, maintaining stable insulation performance even in extreme environments.

Selecting high-quality insulation paperboard requires comprehensive consideration of core properties such as flame resistance, insulation resistance, tensile strength, and arc resistance, as well as the rigorous and applicable manufacturing process to ensure safe, stable, and long-lasting insulation protection in real-world operating conditions.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……