In the design and manufacturing process of dry-type transformers, the selection of insulation materials plays a decisive role in equipment performance, operational reliability, and service life. In recent years, sheet molding compound (SMC) insulation board has gradually become the preferred insulation material for high-end dry-type transformers due to its outstanding comprehensive performance. So, how does SMC insulation board comprehensively enhance dry-type transformer performance across multiple dimensions, including insulation strength, mechanical stability, lightweight and design flexibility, and cost-benefit analysis? This article provides an in-depth analysis.

Excellent insulation performance is the primary prerequisite for the safe operation of dry-type transformers, and SMC insulation board excels in this core requirement.

High Electrical Strength and Arc Resistance: SMC material possesses extremely high dielectric strength, effectively withstanding the high electric field strengths generated during transformer operation, preventing electrical breakdown at the root. Furthermore, its excellent arc resistance minimizes equipment damage caused by arcing, significantly improving operational safety.

Low dielectric constant and dielectric loss: SMC materials maintain a stable dielectric constant and extremely low dielectric loss. This means that in an alternating electric field, the insulation material generates less heat, improving overall equipment efficiency while reducing the risk of potential failures caused by insulation heating.

The mechanical structural stability of dry-type transformers is directly related to the equipment’s short-circuit resistance and long-term operational reliability. SMC insulation board provides strong support for this critical requirement.

High Strength and High Rigidity: SMC insulation board boasts excellent mechanical strength and modulus. The transformer frames, clamps, and support structures made from it are sturdy and durable. Even when the coil is subjected to significant electromagnetic forces during a sudden short circuit, structural deformation or displacement is effectively avoided, thereby preventing serious accidents such as insulation damage.

Excellent Dimensional Stability: SMC material exhibits minimal dimensional change in high and low temperature environments and has a low coefficient of thermal expansion. This ensures that the transformer’s internal structure will not experience stress cracking or loose connections due to material expansion and contraction during thermal cycling, significantly extending the equipment’s lifespan.

Shock and Vibration Resistance: As a composite material, SMC insulation board has excellent energy absorption and dissipation capabilities, effectively buffering the effects of vibration and shock. This ensures secure connections and smooth operation of internal components during transportation, installation, and daily operation.

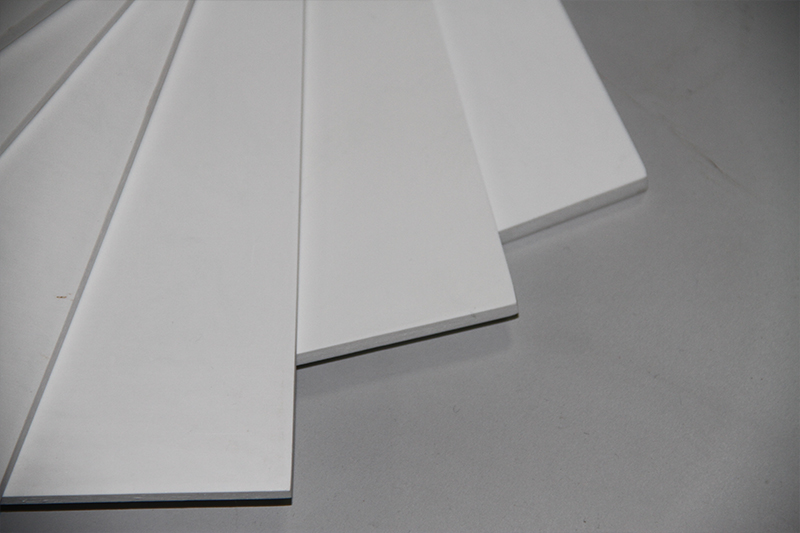

Utilizing a compression molding process, SMC insulation boards achieve lightweight and integrated manufacturing of complex structures, bringing multiple breakthroughs to dry-type transformer design:

Significant Weight Reduction: Compared to metal or ceramic insulation, SMC material has a lower density. Using this material significantly reduces the overall weight of the equipment, making it easier to install and transport in high-rise buildings or in space-constrained environments.

Complex Structure Integrated Molding: SMC material allows for the single-step compression molding of custom-shaped insulation components (such as coil bobbins with heat dissipation slots), reducing subsequent assembly steps and significantly improving production efficiency.

Although the initial purchase cost of SMC insulation board is slightly higher than traditional insulation materials, from a life cycle cost (LCC) perspective, its advantages are significant:

Significantly Reduced Maintenance Costs: SMC insulation board has a long service life and a low failure rate, significantly reducing equipment maintenance frequency and associated costs.

Significantly Extended Replacement Cycles: Compared to traditional materials, SMC insulation board has a significantly longer service life, reducing equipment replacement frequency and minimizing economic losses caused by downtime.

Significant Overall Cost Advantages: From a long-term operational perspective, dry-type transformers using SMC insulation board offer a higher return on investment (ROI), making them particularly suitable for applications requiring extremely high reliability, such as data centers and hospitals.

Q1: What are the main applications for dry-type transformers using SMC insulation board?

A1: Due to its excellent moisture resistance, flame retardancy, environmental performance, and mechanical stability, this type of equipment is particularly suitable for use in harsh environments and locations with high safety standards, such as high-rise buildings, subways, train stations, airports, and mines.

Q2: What is the typical service life of a dry-type transformer using SMC?

A2: Thanks to SMC’s excellent aging resistance, moisture resistance, and heat resistance, dry-type transformers using SMC insulation systems generally have a design service life of over 30 years, with minimal maintenance requirements.

Q3: What are the key differences between SMC insulation boards and DMC (bulk molding compound)?

A3: The glass fibers in SMC are distributed in sheets, making it more suitable for manufacturing large, high-strength flat panels or structural components. DMC (bulk molding compound) has fibers distributed in clusters, making it more suitable for manufacturing small components with complex shapes but relatively low strength requirements. In transformer manufacturing, SMC is primarily used for core structural components such as frames and clamps.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……