In high-voltage electrical equipment, the choice of insulation material directly impacts the equipment’s performance, safety, and service life. Among various insulation materials, G10 epoxy sheet, with its comprehensive and outstanding properties, has become a popular choice among engineers and equipment manufacturers. As a manufacturer specializing in epoxy sheet insulation materials, we will now discuss in detail the unique advantages of G10 epoxy sheet in high-voltage applications.

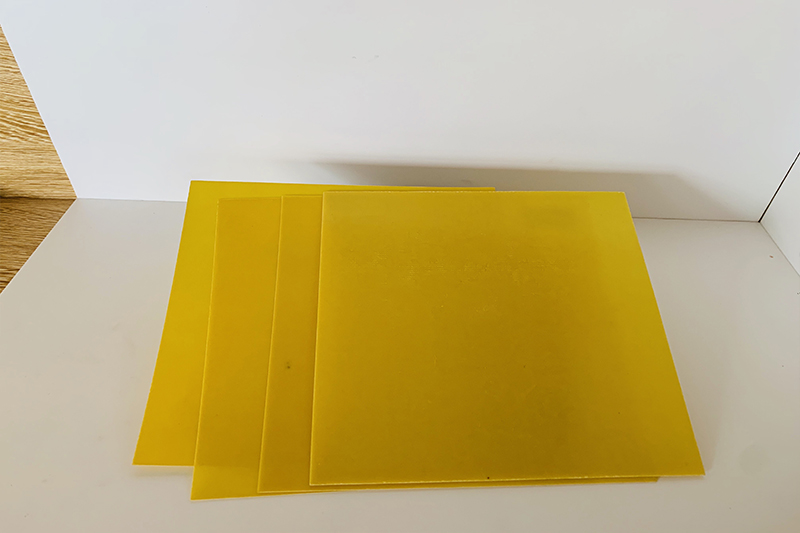

G10 epoxy sheet is an industrial laminate (compliant with NEMA standards). It is a composite material made from electronic-grade fiberglass cloth impregnated with epoxy resin and laminated under high temperature and high pressure. It boasts balanced performance and ease of use, particularly in electrical insulation, and is often used in applications requiring high insulation requirements.

This is the key advantage of G10 epoxy sheet for use in high-voltage environments.

High Dielectric Strength: G10 material boasts a high dielectric strength, effectively resisting breakdown under high electric fields. Even under high voltages of thousands or even tens of thousands of volts, it maintains stable insulation, ensuring equipment safety.

Low Dielectric Constant and Dissipation Factor: These properties minimize energy loss in high-frequency electric fields, reducing heat generation during operation and improving energy efficiency and operational stability—particularly important for critical equipment such as high-voltage switchgear and transformer partitions.

High-voltage equipment is subject to complex mechanical forces during operation, and G10 epoxy sheet is well suited to these challenges:

High Strength and High Rigidity: G10 epoxy sheet offers exceptional mechanical strength and rigidity. It not only serves as a structural support for other components but also withstands the vibration, shock, and electrodynamic forces generated by short circuits during equipment operation, without deforming or breaking easily.

Low Moisture Absorption: G10 epoxy sheet exhibits low water absorption, even in humid environments. This prevents the degradation of insulation performance and dimensional changes caused by water absorption, thereby ensuring long-term stable operation of the equipment.

High-voltage electrical equipment often operates in harsh environments. G10 epoxy sheet’s durability meets diverse requirements:

High-Temperature Resistance: G10 epoxy sheet exhibits excellent heat resistance, with a continuous operating temperature exceeding 130°C. It can withstand the heat generated by normal equipment operation and short-term overloads without experiencing performance degradation due to high temperatures.

Chemical Resistance: G10 epoxy sheet is resistant to most acids, alkalis, solvents, and oils, allowing it to be used in industrial environments exposed to chemicals, extending the overall lifespan of the equipment.

In high-voltage environments, surface discharge and arcing are common causes of equipment failure. G10 epoxy sheet can address this issue:

High CTI (Comparative Tracking Index): G10 material’s high CTI value makes it less likely that arcing and contaminants will form conductive pathways on its surface, preventing surface breakdown and further ensuring equipment safety.

From equipment manufacturing to ongoing maintenance, the advantages of G10 epoxy sheet are evident:

Easy Machining: G10 epoxy sheet can be formed into a variety of complex shapes through standard machining methods such as cutting, drilling, milling, and grinding. This improves production efficiency and meets the customization requirements of different equipment.

Long Lifespan: Due to its stable chemical and physical properties, G10 epoxy sheet exhibits virtually no degradation when used properly, providing decades of reliable insulation protection and reducing costs throughout the equipment’s lifecycle.

Insulating partitions and baffles: Used within switchgear and GIS (gas-insulated switchgear) to separate conductors at different potentials.

Transformer insulation frames and spacers: Provide both structural support and electrical insulation, ensuring stable transformer operation.

Circuit breaker core components: For example, the insulation within the arc extinguishing chamber supports the circuit breaker’s arc extinguishing function.

Insulating platforms for high-voltage test and measurement equipment: Include insulating spacers, brackets, and other components to ensure a safe testing process.

Busbar support insulators: Support and secure current-carrying busbars while ensuring insulation and structural stability.

G10 epoxy sheet is not an ordinary insulation material. Its performance stability and consistency depend primarily on the quality of the raw materials and the controlled production process. Professional epoxy sheet insulation material manufacturers can ensure product quality in three key areas:

Raw material quality: Selecting high-quality electronic-grade glass cloth and epoxy resin prevents impurities from affecting insulation performance.

Precise process control: Precisely controlling the temperature, pressure, and time during lamination ensures uniform lamination, free of bubbles, delamination, and other process issues.

Strict quality testing: Every batch undergoes electrical and mechanical performance testing to ensure it meets or exceeds NEMA G10 standards.

When selecting insulation materials for critical high-voltage electrical equipment, G10 epoxy sheet, with its comprehensive performance, provides a safe, reliable, and cost-effective solution. Choosing a reliable epoxy sheet insulation manufacturer and obtaining the right G10 product for your specific needs is crucial to ensuring long-term, stable operation of your equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……