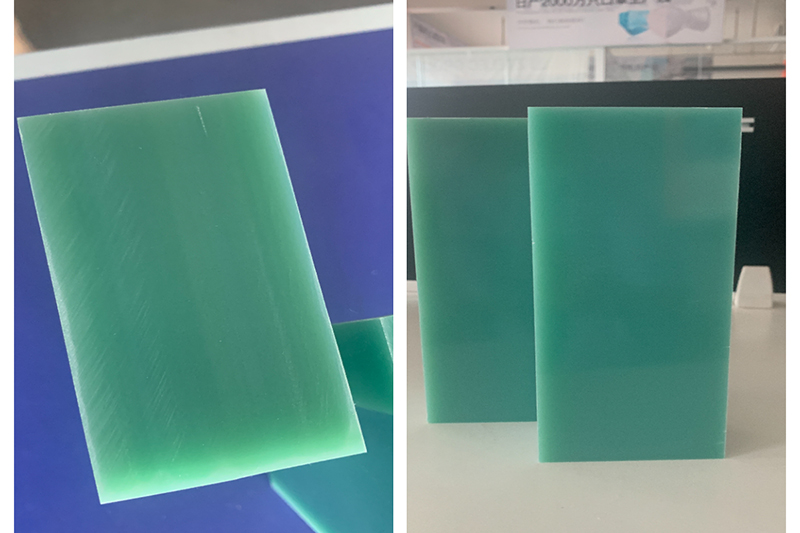

In electrical engineering and high-end manufacturing, the performance of insulation materials directly impacts the reliability, safety, and service life of equipment. Among numerous insulation materials, G10 epoxy sheet, with its excellent overall performance, has become the preferred choice for engineers and designers seeking to enhance the insulation capabilities of electrical equipment. So, what is G10 epoxy sheet? Why does it excel in harsh electrical environments?

G10 epoxy sheet, scientifically known as epoxy glass cloth laminate, is a composite material. It utilizes continuous glass fiber cloth as reinforcement, impregnated with a high-performance epoxy resin, and then cured under high temperature and high pressure. This specialized manufacturing process imparts a range of excellent physical, mechanical, and electrical properties, making it suitable for industrial applications.

If you want to improve the insulation performance of electrical equipment, G10 epoxy sheet offers the following key advantages:

G10 epoxy sheet has high dielectric strength, allowing it to withstand high voltages without breakdown. Its high volume and surface resistivities also effectively prevent leakage current. Its insulation properties remain stable even in humid environments. Therefore, it is often used as an insulating component in high-voltage equipment such as transformers, circuit breakers, switchgear, and busbar supports.

Thanks to its fiberglass reinforcement, G10 sheet has high mechanical strength and rigidity, making it resistant to bending or deformation. It provides a stable structural support for electrical components, resisting vibration and shock during operation, and maintaining dimensional stability over long periods of use.

In humid environments or those subject to large temperature fluctuations, many insulating materials experience a significant deterioration in insulation performance due to water absorption. However, G10 epoxy sheet has extremely low water absorption, allowing it to operate in humid conditions for extended periods without significant degradation of electrical performance, ensuring long-term stable operation of the equipment.

G10 epoxy sheet is resistant to most solvents, acids, and alkalis, making it suitable for complex industrial environments. Furthermore, it has a continuous operating temperature of up to 130°C and can withstand higher temperatures for short periods, meeting the temperature rise requirements of most electrical equipment.

PCB Drilling Backing Board: G10 epoxy board is a common material in the printed circuit board industry, protecting expensive drilling equipment due to its flatness and wear resistance.

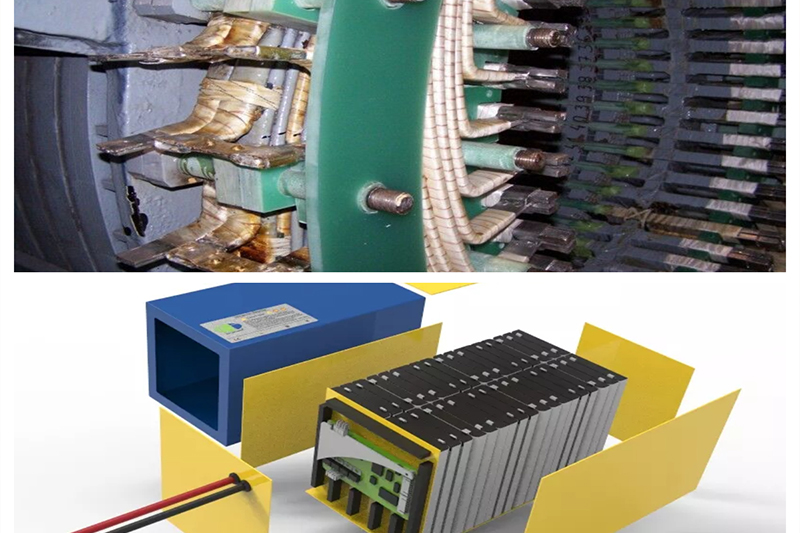

Transformer Insulating Barrier: G10 is used in oil-immersed or dry-type transformers as an insulating barrier between windings.

High-voltage switchgear: G10 epoxy board is used to manufacture insulating brackets, arc-quenching grids, operating rods, etc. to ensure the safe opening and closing of high-voltage circuits.

Motor Slot Wedges and Insulation: G10 epoxy plates secure the coils in the motor while providing turn-to-turn and ground insulation.

Mechanical structural parts: In scenarios that require insulation (such as equipment frames, gears, bearing sleeves, etc.), G10 epoxy boards can be used instead of metal.

When choosing G10 insulation, consider the following factors:

Thickness: Select according to the insulation distance and mechanical strength required by the equipment.

Rating: G10 complies with UL94 V-0 flame retardant rating and can improve equipment safety.

Processability: G10 sheet is easily CNC machined, drilled, milled and cut, and can be made into a variety of complex-shaped parts.

Many people confuse the G10 with the FR-4. Simply put, FR-4 is a flame retardant version of G10. Standard G10 itself is flame retardant, but FR-4 adds a more efficient flame retardant to fully comply with the UL94 V-0 standard. In most electrical equipment that has strict requirements for flame retardancy, FR-4 grade materials are actually used, but the industry often uses “G10” as a general name for this type of material.

If you need a material that can improve the insulation performance of electrical equipment while providing good mechanical support and environmental adaptability, G10 epoxy board is a long-term and reliable choice. It combines high strength, high insulation and durability, and can ensure the safe, stable and long-term operation of electrical equipment in harsh environments.

XUJUE ELECTRICAL is a company with a 65-year history of producing insulation materials. It has a complete industrial chain and a high reputation in the industry. Contact us today for detailed specifications on G10 Epoxy Board to find the right insulation solution for your next project!

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……