Is your Bakelite equipment also experiencing surface wear and shortened lifespan? As a high-performance material, Bakelite’s durability is not static. It depends heavily on the material, craftsmanship, and daily use and maintenance. This article will explore the key factors influencing Bakelite’s wear resistance and share a series of simple maintenance tips to help you maximize its service life.

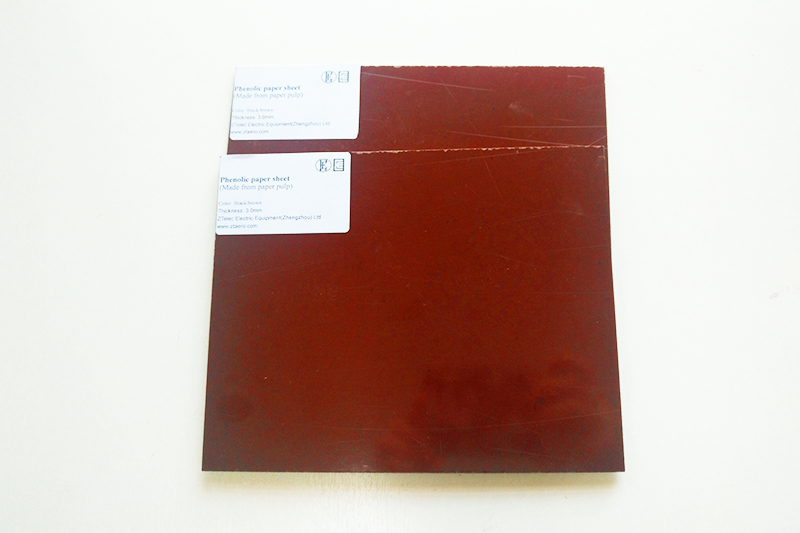

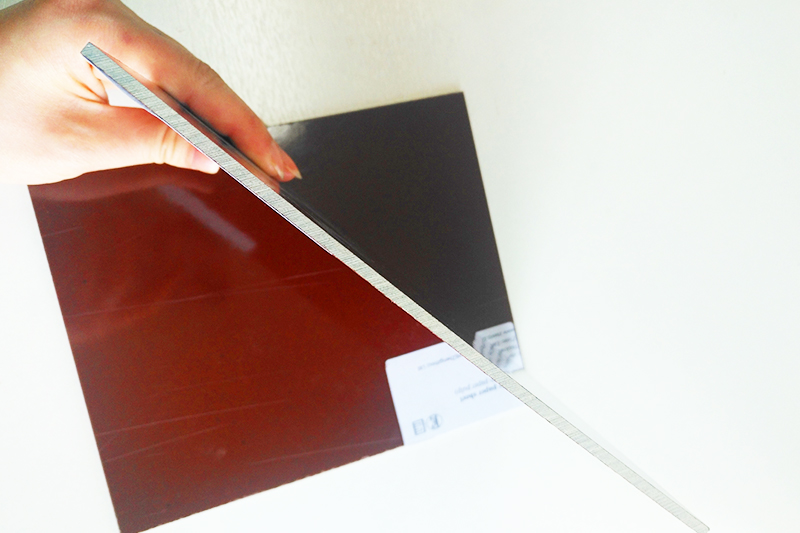

Bakelite, also known as phenolic resin laminate, is a high-pressure laminate made by bonding paper pulp and phenolic resin under high temperature and high pressure. It excels in insulation, moisture resistance, and corrosion resistance, making it widely used in the manufacture of equipment components in the electronics, machinery, and chemical industries. However, over time, due to various factors, Bakelite’s surface is susceptible to wear. This can range from surface loss and fine scratches to deep damage and structural deformation, compromising its insulation performance and structural stability, shortening the overall service life of the equipment. The wear resistance of bakelite isn’t a single, fixed property. And it depends primarily on factors such as the board’s hardness, surface treatment, operating environment, and actual usage.

Generally speaking, the harder the board, the greater its resistance to external friction and impact.

The better the surface treatment, the more it creates a protective barrier on the board’s surface, reducing direct wear. A more suitable operating environment protects the board from extreme conditions.

The more standardized the handling during actual use, the less unnecessary friction and impact.

When these factors are ideal, the bakelite’s wear resistance increases, and its service life also increases.

Material Hardness: Bakelite’s hardness is closely related to the quality of its raw materials and manufacturing process. High-quality raw materials and meticulous manufacturing processes result in higher hardness and superior wear resistance.

Surface Treatment: Bakelite surfaces can be treated with dry film coating, spraying, and polishing. Properly treated surfaces can significantly improve the board’s wear resistance.

Usage Environment: Usage conditions, frequency of use, ambient temperature, and humidity all affect the board’s service life. For example, in humid environments, bakelite is susceptible to corrosion, resulting in a decrease in its hardness.

Proper Moisture-Proof and Water-Proof Measures: Ensure the bakelite’s operating environment is dry and avoid prolonged immersion in water.

Prevent Excessive Wear: When moving bakelite, use tools such as wheels and sliding pads to prevent scratches and impacts on the surface.

Regular Inspection and Maintenance: Regularly inspect the bakelite’s condition. If any problems are found, repair and maintain them promptly. When cleaning bakelite, use a smooth, clean cloth. Avoid using acidic, corrosive, or irritating cleaners.

These are some simple ways to extend the life of bakelite. Developing good usage habits and paying attention to proper usage and daily maintenance can significantly extend the life of bakelite.

A laminate’s wear resistance is one of the most important factors affecting its lifespan, and this resistance is closely related to factors such as material hardness, surface treatment, operating environment, and actual usage. Therefore, to extend the lifespan of a laminate, multiple aspects must be addressed, including ensuring moisture and water resistance, avoiding excessive wear, and maintaining regular inspections and maintenance.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……