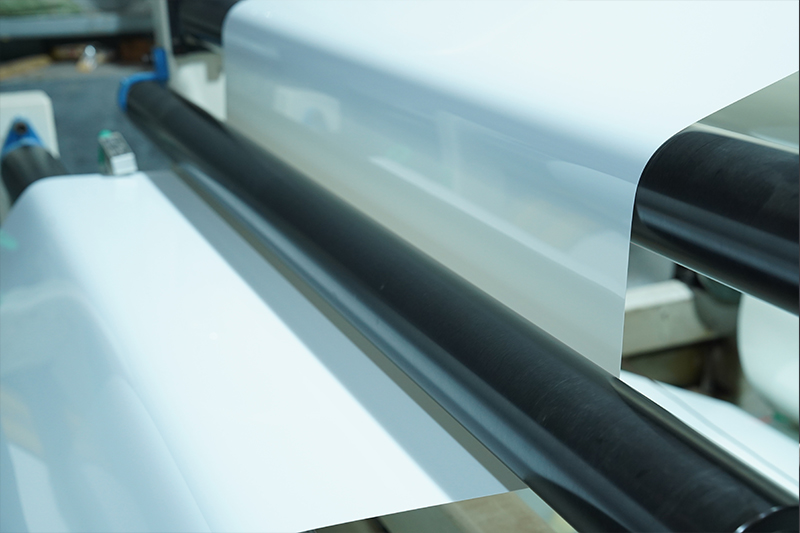

In the manufacturing of dry-type transformers, the selection of winding insulation materials is critical. PET composite films have become a widely used insulation material due to their excellent electrical and mechanical properties. This article explains the advantages, characteristics, and applications of PET composite films in dry-type transformer windings.

Dry-type transformers require insulation materials that can withstand relatively high voltages. PET composite films offer:

High dielectric strength

Stable insulation resistance

Strong resistance to electrical breakdown

When used for inter-turn and inter-layer insulation, PET composite films help reduce partial discharge, improving transformer operational reliability.

During manufacturing and operation, windings are subjected to tensile, compressive, and mechanical stresses. PET composite films feature:

High tensile strength

Good tear resistance

Resistance to deformation and cracking

They are especially suitable for high-speed winding and automated production processes, improving winding consistency.

Modern dry-type transformers typically use Class F (155°C) or Class H insulation systems. PET composite films generally provide:

Class F thermal resistance

Higher temperature resistance after special treatment

This allows PET composite films to meet the long-term thermal requirements of transformer operation.

Compared with some high-end insulation materials, PET composite films are easier to process:

Easy to cut and form

Suitable for both manual and machine winding

PET composite films help reduce transformer manufacturing costs while maintaining reliable performance.

Dry-type transformers are oil-free, offering high safety and environmental benefits. PET composite films share similar advantages:

Low smoke and fewer harmful gases during combustion

Compliance with environmental and safety standards

As a result, PET composite films are well suited for use in shopping malls, hospitals, subways, data centers, and other applications with high safety requirements.

♦ Inter-turn insulation of high- and low-voltage windings

♦ Inter-layer insulation of windings

♦ End-winding insulation structures

♦ Auxiliary and reinforced insulation positions

In practice, PET composite films are often used together with epoxy resin, glass fiber, and other materials to form a complete insulation system.

While PET composite films demonstrate excellent performance, specific precautions should be observed during application:

Temperature control: Ensure operating temperatures do not exceed the material’s allowable limits.

Proper handling: Wrap evenly to avoid folds or damage.

Compatibility check: Confirm the material is compatible with resins, wire coatings, and other components used.

Use qualified products: Purchase products that comply with standards such as IEC or UL.

As transformers increasingly pursue higher efficiency, compact size, and environmental friendliness, PET composite films are also evolving:

Nanocomposite technology: Incorporation of nanomaterials to enhance corona resistance, thermal conductivity, or mechanical strength.

Eco-friendly materials: Development of recyclable or bio-based PET to reduce environmental impact.

Higher thermal classes: Modified or composite processes to achieve H-class (180°C) or higher temperature resistance.

Digitalization and intelligence: The functional materials which can reflect the insulation state are developed by combining the online monitoring.

Due to their high dielectric strength, mechanical strength, thermal resistance, and cost-effectiveness, PET composite films have become a key insulation material for dry-type transformer windings. With technological advances, they will continue to help transformers achieve higher efficiency, smaller size, and longer service life. For transformer manufacturers, understanding and properly using this material contributes to producing more competitive products.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……