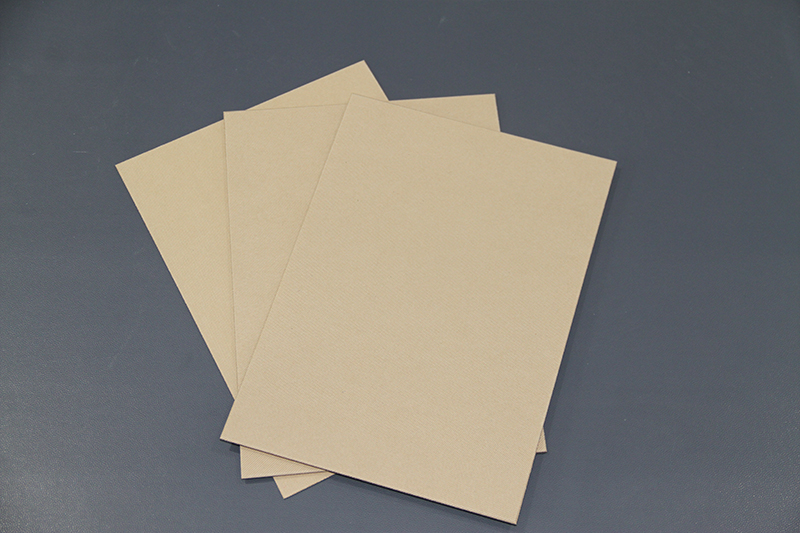

Electrical pressboard is an indispensable base material in the insulation systems of power equipment. Among the many grades available, T3 and T4 are the two most widely used types. Both are made from high-quality wood pulp fibers and produced through high-pressure pressing and thermal treatment. However, they differ significantly in performance, application, thermal class, and overall cost-effectiveness.

This article provides a comprehensive comparison between T3 and T4 electrical pressboards, helping you make the right choice for your transformer, motor, or other electrical equipment. We will examine their standard origins, performance parameters, and application fields to clarify the key distinctions between the two.

This is the most fundamental distinction between T3 and T4 pressboards.

T3 Electrical Pressboard:

The classification and performance indicators of T3 pressboard are mainly based on Chinese industry standards. These standards are formulated according to the development needs and production capabilities of China’s electrical manufacturing sector, making T3 highly accepted in the domestic market.

T4 Electrical Pressboard:

The “T4” designation primarily originates from the International Electrotechnical Commission (IEC) standards. IEC standards are globally recognized and authoritative, with unified and stringent requirements for material performance and testing methods.

Because the two grades follow different standard systems, their technical and performance parameters vary significantly.

Electrical Strength (Breakdown Voltage):

This is the core indicator of insulation materials. T4 insulation pressboard is designed for higher-end applications, with much stricter requirements for dielectric strength. It maintains superior performance consistency across various thicknesses.

Thickness Uniformity and Density:

High-voltage equipment demands uniform insulation performance across all sections. T4 insulation pressboard offers tighter control over thickness tolerance and density, ensuring stable electrical behavior even under complex electric fields.

Impurity Content and Cleanliness:

Conductive impurities in the paperboard can reduce insulation performance and increase the risk of partial discharge. During production, T4 insulation pressboard follows more rigorous impurity control standards, ensuring higher material purity and enhanced electrical reliability.

The performance gap between T3 and T4 electrical pressboards directly determines their respective application ranges.

T3 Electrical Pressboard:

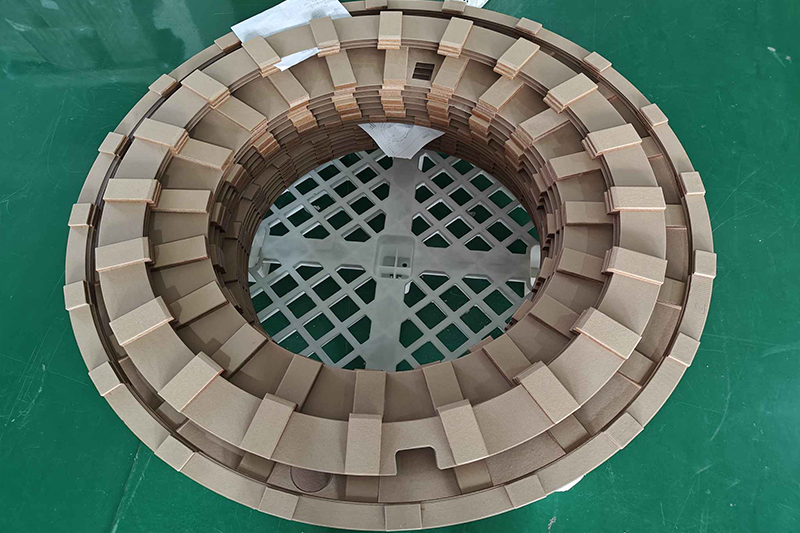

With reliable performance and cost advantages, T3 pressboard is widely used in domestic 10 kV and 35 kV medium- and low-voltage oil-immersed transformers, reactors, and instrument transformers. In these devices, it primarily serves as interlayer insulation, spacers, and barriers, effectively meeting standard insulation needs at a competitive price.

T4 Electrical Pressboard:

T4 is designed for applications requiring superior insulation performance, such as extra-high voltage (EHV) and ultra-high voltage (UHV) transformers (500 kV, 750 kV, 1000 kV), large generator units, and export projects aligned with IEC or international standards. In these critical systems, insulation failure can lead to severe equipment damage or power outages, making high-performance T4 material indispensable.

When selecting between T3 and T4, several key factors should be considered:

For medium- and low-voltage, standard equipment, T3 insulation pressboard offers the best cost-performance balance.

For high-voltage, ultra-high-voltage, critical, or export-oriented equipment, T4 insulation pressboard must be used to meet IEC insulation performance requirements.

If the equipment is designed, manufactured, and tested primarily under Chinese GB/JB standards, T3 is acceptable.

If the project follows IEC standards or the client specifically requires international compliance, T4 is the correct choice.

T4 insulation pressboard involves stricter material selection and production processes, making it more expensive than T3. In practice, the goal should be to balance cost efficiency with performance reliability, ensuring safety without unnecessary expense.

Regardless of the grade, always choose a reputable manufacturer with certified quality systems.

For T4 insulation pressboard in particular, ensure the supplier can provide IEC 60641-3-2 compliance reports issued by recognized testing institutions.

By comparing the two insulation materials, the distinctions become clear:

T3 Electrical Pressboard is economical and practical, and it is ideal for standard electrical equipment.

T4 Electrical Pressboard offers superior electrical strength, stability, and reliability, making it suitable for modern high-voltage and special applications.

When selecting the proper insulation pressboard type, engineers should comprehensively evaluate operating voltage, thermal environment, mechanical stress, and expected service life. Choosing the appropriate insulation pressboard ensures long-term stable, safe, and efficient operation of electrical equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……