Among electrical insulating materials, T4 electrical paper board has become a commonly used key material in transformers, motors, and other equipment due to its excellent performance, providing crucial support for the safe operation of these devices. If you are looking for reliable insulating materials for electrical equipment, it is very necessary to understand T4 electrical insulating board.

This article will start with the definition and introduce the basic characteristics and common applications of T4 electrical paper board in detail, and provide specific selection suggestions to help you make the right choice.

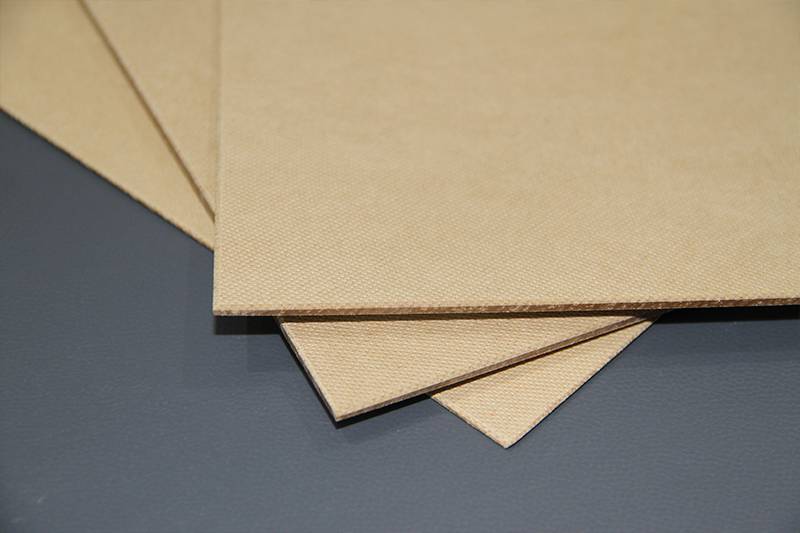

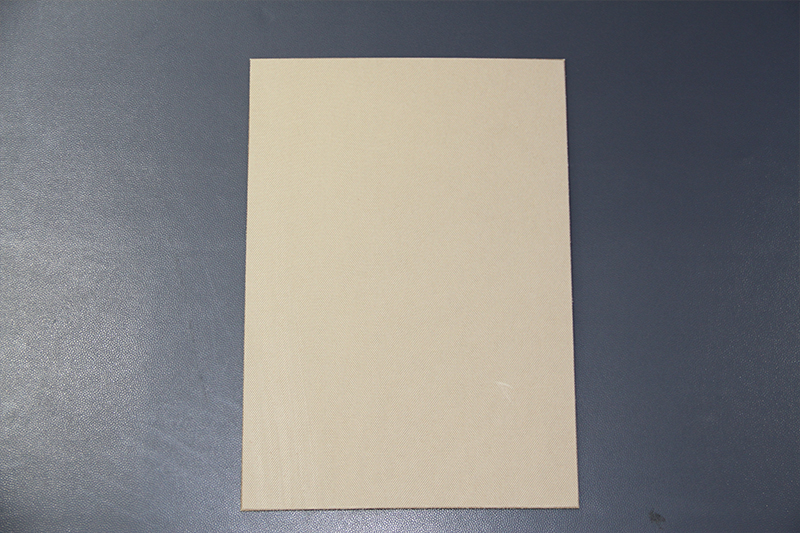

T4 electrical paper board is a hard fiber insulating board made from sulfate wood pulp. “T4” indicates that it belongs to the thermoplastic material category. This means that the material has undergone specialized heat treatment and calendering processes, resulting in high mechanical strength and heat resistance. T4 electrical paper board has a high density, is easy to process, and has excellent electrical insulation properties. It is often used to manufacture insulating components in transformers, such as insulating end rings, spacers, and support rods.

T4 paper board has high electrical strength and can effectively resist electric field stress, preventing leakage or breakdown, ensuring the safe operation of high-voltage equipment.

T4 paper board is highly compressed with a very tight structure. It has high tensile and compressive strength, capable of withstanding the electromagnetic force, vibration, and shock of transformer windings without deformation or damage.

The internal structure of the paperboard is uniform, facilitating the rapid penetration of transformer oil, insulating varnish, and other liquids. These liquids can fill the internal voids, thereby enhancing insulation performance and mechanical strength, as well as moisture resistance.

As a thermoplastic material, T4 paper board can operate at high temperatures for long periods, typically up to 105°C or higher. Under such conditions, its mechanical and electrical properties do not significantly decline, ensuring the reliability of equipment when heated.

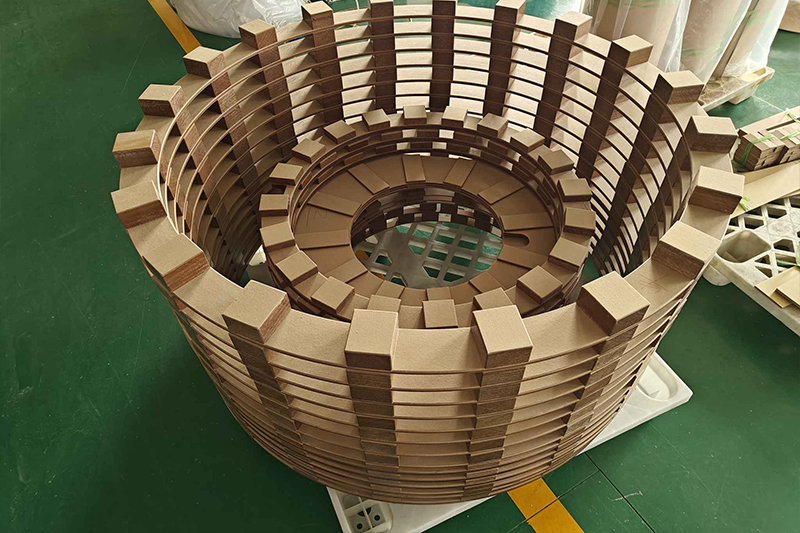

T4 electrical paper board is easy to process through stamping, cutting, winding, drilling, etc., allowing for the flexible production of various shaped insulating components to meet the customized needs of different equipment.

T4 electrical paper board has outstanding comprehensive performance and has core application value in the following fields:

Oil-immersed transformers: This is its main application scenario, and it is often used to make:

♦ Insulating end rings and spacers: To isolate high and low voltage windings;

♦ Support strips and spacers: To form oil channels, promoting the flow of insulating oil and heat dissipation;

♦ Corner rings: To optimize the electric field distribution and prevent partial discharge.

Motors and generators: Used as slot wedges, insulating gaskets, and interphase insulating materials.

High-voltage electrical equipment: Such as switchgear and transformers, used as internal insulating structural components.

Correct selection is crucial for equipment performance and safety. When choosing T4 electrical paper board, it is recommended to focus on the following aspects:

Strict thickness control helps ensure consistent insulation distance and assembly accuracy. Products with stable production processes and good thickness control should be selected.

Density directly determines the mechanical strength and electrical performance of the cardboard. Generally, the higher the density, the better the performance. However, it should also be noted that high density may increase processing difficulty.

Excessive moisture can reduce insulation performance and even cause bubbles during operation, leading to faults.

Evaluate the quality of the paperboard based on the actual processing method. High-quality T4 paperboard has smooth edges after processing, without layering or burrs.

Choose well-known brands or suppliers with good reputation and relevant industry certifications (such as ISO9001). This helps to obtain stable quality and reliable performance products.

T4 electrical paper board, as a reliable insulation material in power equipment, plays an important role. By understanding its characteristics such as high strength, high insulation, good impregnation, and thermal stability, and combining with your actual application requirements and selection criteria, you can select the most suitable T4 electrical paper board for electrical equipment. This will lay a solid foundation for the long-term safe operation of the equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……