In the sophisticated insulation system inside extra-high-voltage (EHV) transformers, T4 electrical pressboard plays a crucial role. It functions both as a mechanical support and as an electrical insulation barrier. This article explains the core functions, key performance indicators, and selection guidelines of T4 electrical pressboard in EHV transformers, providing comprehensive reference for engineers, procurement teams, and technical decision-makers.

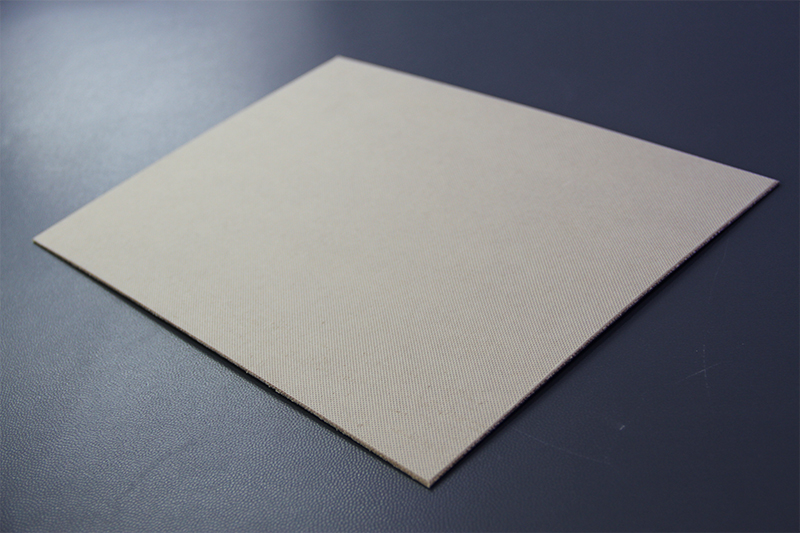

T4 electrical pressboard is an internationally recognized designation (in accordance with IEC standards), referring to a high-performance pressboard with specific density and properties. Made from high-purity sulfate wood pulp and manufactured through a specialized pressing process, it offers high mechanical strength and excellent electrical insulation performance.

EHV transformers cover voltage levels of 220 kV, 500 kV, 1000 kV, and above, where extremely high electric field strength imposes stringent requirements on insulation materials. With the following advantages, T4 electrical pressboard has become an indispensable material in this field:

T4 electrical pressboard can withstand extreme electrical stress in EHV environments, preventing insulation breakdown and ensuring safe transformer operation.

With high rigidity, it supports and secures winding structures, enduring electrodynamic forces during short circuits to prevent deformation.

T4 electrical pressboard maintains stable performance under long-term transformer operation at 105°C and above, slowing down aging.

Free of conductive impurities, it is highly compatible with transformer oil and does not accelerate oil aging, ensuring long-term reliability of the oil–paper insulation system.

Its porous structure enables excellent oil impregnation, forming a high-quality oil–paper composite insulation that enhances dielectric performance.

In extra-high-voltage (EHV) and ultra-high-voltage (UHV) transformers, T4 electrical pressboard serves both structural support and electrical insulation functions. It is mainly used for manufacturing the following components:

♦ Spacers, blocks, and rings

♦ Reactor support components

♦ Core clamps and electrode support structures

♦ High-voltage winding barriers

♦ Layer insulation and phase-to-phase insulation

♦ Winding insulation assemblies

T4 electrical pressboard has excellent oil absorption capability and high compatibility with transformer oil, making it suitable for long-term operation in oil-immersed equipment.

In UHV systems, T4 electrical pressboard can withstand electromagnetic forces and short-circuit impacts.

To ensure optimal equipment performance, the selection of T4 electrical pressboard should consider the following factors:

Common thickness ranges from 1 mm to 50 mm.

Applications closer to the high-voltage area require greater thickness.

High-density grades are suitable for structural components such as support blocks and clamps.

Medium-density grades are used for winding insulation structures.

Choose high-quality T4 pressboard that meets IEC, ISO, and GB international standards to ensure oil compatibility and long-term stability.

Depending on the application, select modes compatible with cutting, milling, punching, or laminating processes.

As transformer technology advances toward higher voltage levels, smaller size, higher efficiency, and greater environmental friendliness, T4 electrical pressboard continues to evolve:

Development of new pressboard grades with higher thermal classes (F-class or H-class), greater mechanical strength, and lower dielectric loss.

Adoption of more sustainable raw materials and manufacturing processes.

Integration with materials such as Nomex® to create composite insulation materials that combine multiple performance advantages.

With the continuous increase of transformer capacity and voltage levels, the performance requirements for insulation materials are becoming increasingly strict. Leveraging its excellent thermal stability, mechanical strength, and electrical performance, T4 electrical pressboard remains a core material ensuring the safe operation of modern power systems.

If you require high-quality T4 electrical pressboard, selection guidance, or customized machining services, please contact our team for professional solutions.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……