In the fields of electrical engineering, motor manufacturing, and transformer production and maintenance, choosing the right insulating material is essential to ensure long-term stability and safe operation of equipment. As a composite insulation material with excellent performance, DMD insulation paper is widely used. If you are looking for insulation solutions for your 2025 projects and want to understand reliable purchasing channels for high-quality DMD insulation paper, this article provides the information you need.

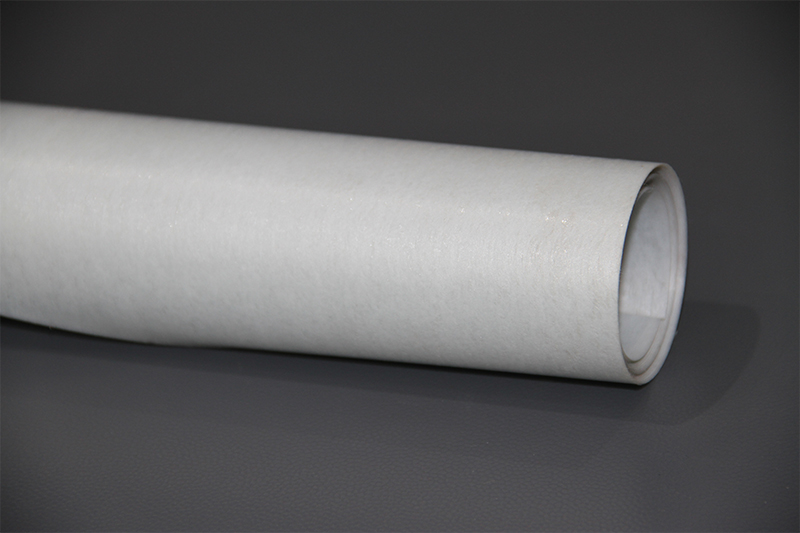

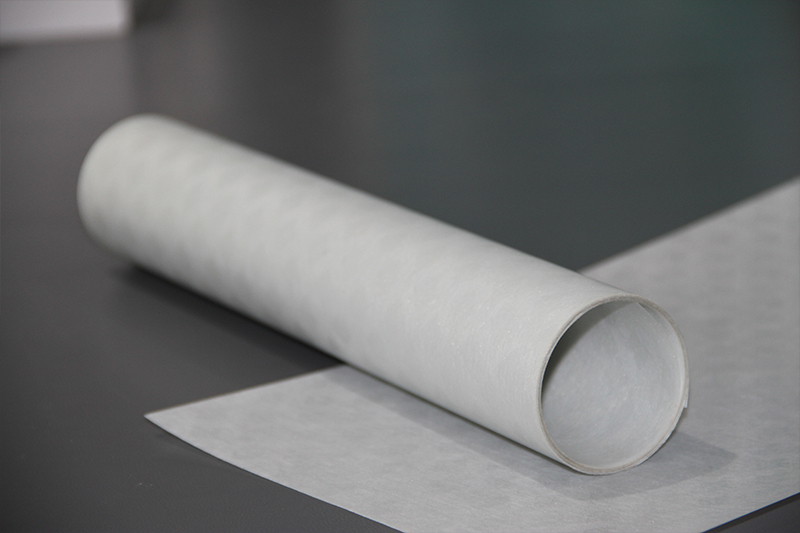

DMD is the abbreviation for Dacron-Mylar-Dacron, a flexible insulating material composed of a three-layer laminate structure:

– Outer Layers: Two layers of polyester non-woven fabric

– Middle Layer: One layer of polyester film

This structure gives DMD insulation paper excellent electrical insulation, mechanical strength, and heat resistance, making it suitable for both Class B (130°C) and Class F (155°C) insulation systems.

With the development of industrial technologies and the growth of the new energy sector, the application range of DMD insulation paper will further expand in 2025. Its core application areas include:

DMD insulation paper is commonly used for interlayer and inter-turn insulation in dry-type transformers. With excellent dielectric strength and mechanical toughness, it helps prevent breakdown and ensures stable transformer operation under high-voltage conditions.

In traditional industrial motors, electric vehicle drive motors, wind turbines, and other equipment, DMD insulation paper is widely applied in slot insulation, phase insulation, and liner insulation. It withstands electromagnetic vibration and high temperatures generated during operation.

In 2025, the demand for photovoltaic inverters, energy storage systems, charging stations, and other new energy facilities will continue to rise. Inductors and transformers in these devices require DMD insulation paper to meet the needs of high power density and long-term reliable performance.

During coil rewinding and equipment refurbishment, motor repair shops and transformer maintenance centers must use DMD insulation paper.

Small and medium-sized motors: Class B

Transformers and reactors: Class F

Common thicknesses include 0.18 mm, 0.20 mm, 0.25 mm, 0.30 mm, and 0.35 mm.

The greater the thickness, the higher the mechanical strength—suitable for:

♦ High-power transformers

♦ High-frequency equipment

♦ High-voltage applications

VPI vacuum pressure impregnation: Choose models with excellent varnish absorption

Dry-type equipment: Choose models with strong thermal resistance and arc resistance

Factory Direct Supply is ideal for motor manufacturers, transformer factories, and reactor manufacturers with bulk procurement needs.

Using ZTelecgroup as an example:

♦ Over 65 years of experience in insulating material production

♦ Certified by ISO, CE, and RoHS

♦ Supplies a full range of DMD insulation paper for dry-type transformers and motors

♦ Customizable width, thickness, and thermal class

♦ Supports OEM/ODM and export engineering solutions

Best for: non-standard projects, large-volume orders, international supply chain cooperation.

Platforms such as Alibaba International and Made-in-China, are suitable for small-batch purchases by overseas buyers, allowing easy comparison of price and lead time.

It is ideal for customers requiring immediate delivery and rapid usage.

Suitable for large-scale projects in new energy, petrochemical, and substations, enabling centralized supply.

DMD insulation paper offers safe, efficient, heat-resistant, and economical performance, and will remain a widely used insulating material in electrical, motor, and new-energy applications in 2025.

If you need factory-direct DMD insulation paper, transformer/motor insulation solutions, or export-certified materials, feel free to contact us for technical data, samples, and same-day quotations.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……