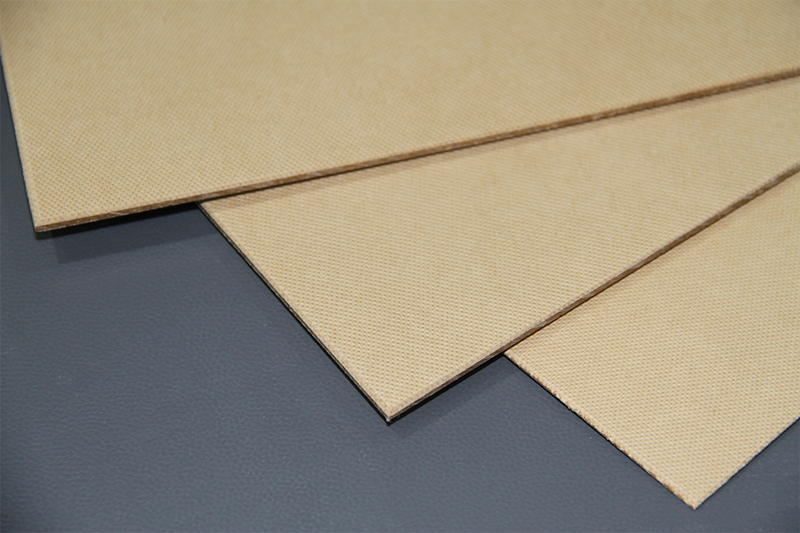

Electrical paper pressboard is a cellulose-based insulating material widely used for electrical insulation protection in various power equipment. With its high mechanical strength and excellent dielectric performance, it plays a critical role in transformers, current transformers, motors, and other electrical systems, serving as a foundational material to ensure safe and stable operation.

Electrical pressboard features high dielectric strength and mechanical robustness. It has low shrinkage and good flatness, making it suitable for high-frequency vibration environments without suffering performance degradation or damage.

The relative permittivity (dielectric constant) is an important indicator of the material’s dielectric polarization. This property is sensitive to temperature and moisture, so it must be evaluated based on the actual application environment.

The surface resistivity directly influences the pressboard’s electrical conductivity. Impurities or additives introduced during processing may alter carrier concentration, thereby affecting resistivity. This must be carefully controlled during manufacturing and selection.

Interlayer Insulation: Used between transformer windings to prevent inter-turn short circuits and ensure reliable insulation.

Barriers and Spacers: Support winding structures and maintain coil positioning while preserving insulation integrity.

Lead Insulation: Wrapped around conductors to prevent leakage or breakdown, ensuring safe operation of leads.

Oil Channel Separation: In oil-immersed transformers, pressboard separates oil ducts to enhance cooling and insulation.

Slot Insulation: Inserted into stator or rotor slots to isolate windings from the core and prevent short circuits.

Phase-to-Phase Insulation: Separates windings of different phases to avoid phase-to-phase faults.

End Support: Provides structural support at winding ends to resist electromagnetic vibration and maintain stability.

Commutator Liners: Used in DC motors to insulate and support commutator segments, ensuring safe commutation.

Breaker Barriers: Prevent inter-phase discharge by isolating arcs, enhancing operational safety of breakers.

Insulating Pads: Support conductive components and prevent direct contact between metal parts.

Cabinet Insulation: Installed on switchgear walls to increase overall insulation rating and reduce fault risk.

Voltage Level:

Low Voltage (≤10kV): Thin soft pressboards (e.g., Type A) are suitable.

Medium–High Voltage (10kV–220kV): Use medium to thick rigid pressboards (e.g., Type B).

Ultra-High Voltage (≥500kV): High-density rigid pressboards with arc-resistant coatings are recommended.

Mechanical Stress:

Vibration or Impact Environments: Choose high-strength, compression-resistant pressboards.

Static Support Only: Standard-density pressboards are sufficient.

Environmental Conditions:

Oil-Immersed: Oil-resistant pressboards are required to maintain insulation performance.

Humid Environments: Moisture-resistant pressboards with low water absorption are recommended.

High-Temperature Conditions: Choose E-class (120°C) or H-class (180°C) modified pressboards that can withstand high heat.

Standards Compliance:

Always select products that comply with GB/T 19264.3 or IEC 60641-3-1 to ensure quality and performance.

Cost vs. Performance Balance:

Nano-Modified Pressboard: Offers superior performance but comes at a higher cost, suitable for UHV or highly demanding scenarios.

Recycled Fiber Pressboard: Environmentally friendly, but users must verify that its dielectric strength meets application requirements.

Validation and Testing:

For extreme environments, it’s advisable to conduct type tests (e.g., combined high temperature, humidity, and voltage tests) to ensure stable and reliable performance.

By understanding the properties, application scenarios, and key selection criteria of electrical paper pressboard, engineers and procurement professionals can make informed decisions that optimize performance, reliability, and cost in their electrical systems.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……