In the design and manufacture of electrical equipment, electrical paperboard is a key insulation and structural support material, and its performance directly determines the reliability, safety and service life of the equipment. However, facing the wide variety of electrical paperboards on the market, how to accurately select according to factors such as equipment operating conditions, voltage levels, and environmental adaptability has become a core skill that engineers must master.

The heat resistance level of electrical paperboard must strictly correspond to the insulation level of electrical equipment:

Class A insulation materials (105℃) cannot replace Class B (130℃) or higher materials, otherwise it will accelerate aging and shorten the life of the equipment;

High heat resistance materials used in low-requirement scenarios will cause resource waste.

Typical scenarios

High temperature environment: Motors near steel plants and boiler rooms need to use Class F (155℃) or Class H (180℃) electrical paperboard to ensure long-term stable operation under high temperatures.

Extreme environment: Aviation, nuclear power and other fields need to use Class C (220℃ and above) electrical paperboard to meet extreme temperature requirements.

Electrical paperboard must have sufficient mechanical strength to withstand vibration, electromagnetic force, etc. during equipment operation:

There must be no less than two sheets of interlayer insulation paper;

Two sheets of 1.5mm thick paperboard are generally required to roll the insulation tube.

Typical scenarios

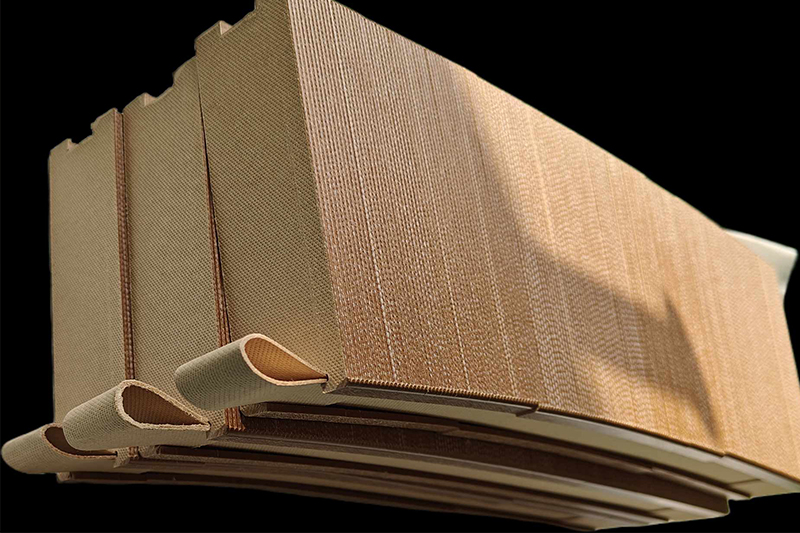

Vibration environment: For motors in textile mills and paper mills, electrical paperboard with high tear strength and good flexibility, such as DK50/50 paperboard mixed with cotton fiber, must be selected to prevent insulation damage caused by vibration.

Complex structure: For motor slot wedges, transformer coil ends and other parts, hard steel paperboard or glass fiber reinforced composite steel paper tube with good machining performance must be selected to ensure structural stability and insulation reliability.

The insulation strength of different electrical paperboards varies significantly, and needs to be selected according to the voltage level and dielectric requirements of the equipment:

The insulation strength of capacitor paper is better than that of cable paper, and cable paper is better than that of insulating paperboard.

Typical scenarios

High-voltage equipment: For high-voltage cable insulation of 110kV and above, high-voltage cable paper (thickness 0.045~0.125mm) must be selected, which has low dielectric loss and stable insulation performance.

Precision instruments: Electrical paperboard with high resistivity and little influence of temperature and humidity should be selected to ensure the accuracy and long-term stability of the instrument.

Electrical paperboard needs to adapt to the temperature, humidity, chemical corrosion and other conditions of the equipment operating environment:

For example, chemical plant motors need to use corrosion-resistant polyimide film or electrical paperboard to prevent insulation failure due to chemical corrosion.

Typical scenarios

Chemical corrosion environment: Chemical plants, electroplating workshops, etc., need to use chemical corrosion-resistant electrical paperboard (such as glass fiber reinforced insulation materials) to ensure long-term and stable operation of the equipment.

Outdoor environment: Wind power and photovoltaic equipment, need to use UV-resistant and aging-resistant electrical paperboard (such as TFT composite materials) to extend the service life of the equipment.

The thickness of electrical paperboard increases after moisture absorption and decreases after drying. It is necessary to select materials with appropriate compression coefficient according to the equipment operating environment:

In humid environments, moisture-proof electrical paperboard or composite materials need to be used to reduce the impact of deformation on insulation performance.

Typical scenarios

Humid environment: Coastal areas or underground substations, need to use electrical paperboard with good moisture-proof performance (such as polyester fiber paper and polyester film composite products) to prevent insulation performance from decreasing due to moisture absorption.

Precision manufacturing: When repairing a transformer, it is necessary to consider the impact of cardboard deformation and shrinkage on the insulation structure, and select electrical cardboard with good dimensional stability (such as high-density electrical cardboard) to ensure the quality of the repair.

To select suitable electrical cardboard for electrical equipment, it is necessary to comprehensively consider multiple aspects such as heat resistance, mechanical, insulation, environmental adaptability and compression coefficient, and then combine the specific application scenarios and operating requirements of the equipment. This can ensure the safe and stable operation of the equipment, extend its service life, and avoid waste of resources. In the actual selection process, you can also refer to relevant industry standards and equipment manufacturers’ suggestions to make the selection more scientific and reasonable.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……