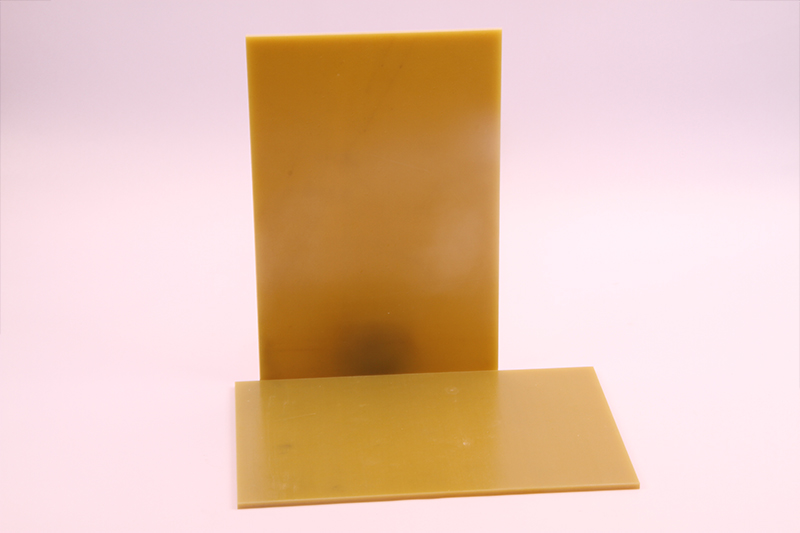

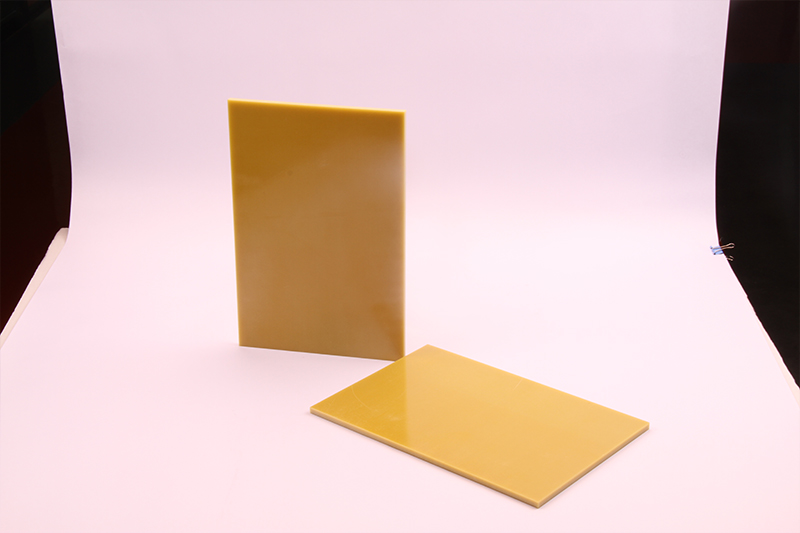

3240 epoxy sheet, formally known as epoxy glass fiber laminated sheet, is a high-performance insulating material made by laminating epoxy resin with glass fiber cloth under high temperature and pressure. With its exceptional electrical insulation, mechanical strength, and processing versatility, 3240 epoxy sheet has become an essential component in the electromechanical engineering sector, widely used in the manufacturing and upgrading of various electrical equipment.

Electrical Insulation: 3240 epoxy sheet offers very high insulation resistance and breakdown voltage, effectively preventing current leakage and significantly reducing the risk of electrical faults at the source.

Mechanical Strength: With excellent tensile, flexural, and compressive strength, 3240 sheet can endure complex mechanical stresses without damage, ensuring high structural stability.

Heat Resistance: It maintains stable performance under high temperatures, making it suitable for the long-term high-temperature operation required by most electromechanical systems.

Corrosion Resistance: 3240 epoxy sheet exhibits strong resistance to acids, alkalis, and organic solvents, enabling reliable performance in harsh chemical environments over extended periods.

Insulation Frameworks in Motors and Transformers:

3240 epoxy sheet is used to accurately position winding coils, ensuring physical separation of conductive components.

Insulating Barriers in Switchgear and Distribution Boxes:

It effectively prevents phase-to-phase short circuits or ground breakdown accidents, thereby enhancing the overall safety of power distribution systems.

Critical Components in High-Voltage Testing Equipment:

3240 epoxy sheet serves as an insulating support in power frequency withstand voltage test benches, directly impacting testing accuracy and operational safety.

Core Performance Advantages

✅ High Insulation Standard:

3240 epoxy sheet is ideal for high-voltage applications, capable of effectively blocking current leakage.

✅ Robust Mechanical Support:

It can reliably bear mechanical stress from electrical components without deformation or damage.

✅ Arc Resistance:

3240 sheet resists carbonization under arc exposure, significantly extending the service life of equipment.

Motor Slot Wedges: 3240 epoxy sheet is used to secure stator and rotor windings in place, preventing loosening or displacement during high-speed operation.

End Insulating Blocks: It provides insulation between the winding ends and the motor housing, structurally eliminating potential short-circuit risks.

Commutator Insulation Sheets: In DC motors, 3240 epoxy sheet serves as an insulating layer between commutator segments.

Performance Advantages

✅ High Temperature Resistance:

3240 epoxy sheet is suitable for F-class insulated motors and maintains stable performance during long-term high-temperature operation.

✅ Dimensional Stability:

With a low coefficient of thermal expansion, it resists heat-induced deformation, preventing structural failure.

✅ Environmental Adaptability:

3240 epoxy sheet is oil-resistant and chemically corrosion-resistant, making it suitable for oil-cooled motors and chemically aggressive environments.

Thanks to its dimensional stability and heat resistance, 3240 epoxy sheet is widely used as a critical auxiliary material in electronics manufacturing.

PCB Drilling Backing Boards: 3240 epoxy sheet protects the machine bed from drill damage and improves hole position accuracy.

SMT Reflow Soldering Fixtures: It withstands the high temperatures of lead-free soldering without warping, ensuring soldering quality.

High-Voltage Test Fixtures: 3240 epoxy sheet serves as an insulating support base for dielectric withstand testing platforms, ensuring a safe and stable testing process.

Performance Advantages

✅ Outstanding Dimensional Stability:

With low water absorption, 3240 epoxy sheet avoids deformation caused by moisture.

✅ Wide Temperature Tolerance:

It is capable of withstanding high temperatures (including short-term peaks), and meets diverse process requirements.

✅ Flexible Machinability:

3240 epoxy board can be processed into complex shapes to meet the requirements of customized fixtures.

Insulation Plates for Inverters and Power Modules: 3240 epoxy sheet can block heat conduction paths, shielding nearby sensitive components from high temperatures.

Welding Machine Protective Covers: With its flame-retardant properties, 3240 epoxy sheet can resist damage from sparks and spatter during welding.

High-Temperature Sensor Mounts: It serves as an insulating support for thermocouples and infrared thermometers, meeting both insulation and heat resistance requirements.

Performance Advantages

✅ High Flame-Retardant Rating:

Compliant with UL94 V-0, 3240 epoxy sheet is self-extinguishing when removed from flame, reducing fire risk.

✅ Efficient Thermal Insulation:

It effectively blocks heat transfer, protecting heat-sensitive components.

✅ Excellent Aging Resistance:

3240 epoxy board is not prone to brittleness in long-term high-temperature environments and maintains stable performance.

Bearing Bushings and Guide Rail Pads: 3240 epoxy sheet helps reduce friction noise and enhances operational smoothness of machinery.

Light-Duty Transmission Parts: Gears, pulleys and other components made of 3240 epoxy board are suitable for environments with high anti-corrosion requirements such as food machinery.

Performance Advantages

✅ Lightweight Advantage:

With lower density than most metals, 3240 helps reduce overall equipment load.

✅ Self-Lubricating Properties:

Its low friction coefficient makes it suitable for oil-free lubrication applications.

✅ Outstanding Weather Resistance:

3240 does not rust and is resistant to corrosion, making it suitable for complex environments such as dampness, acids and alkalis.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……