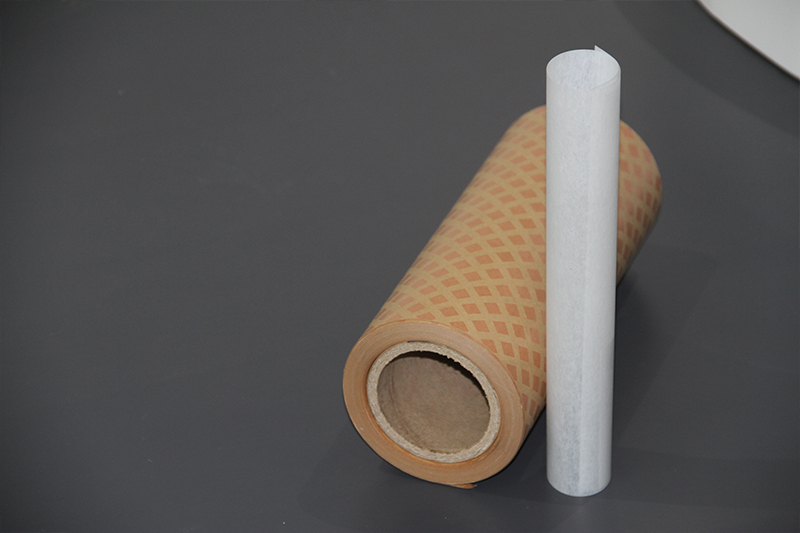

In the insulation systems of power equipment, the performance of DDP (Diamond Dotted Paper) is closely related to the density of its diamond pattern. Choosing an appropriate diamond density allows the material to achieve optimal electrical and mechanical properties, thereby ensuring the stable operation of power equipment. Below is a detailed guide on how to select the best diamond density for DDP.

The diamond density of DDP refers to the number of diamond-shaped grids within a unit length of the material. It is commonly measured in “mesh,” which indicates the number of grid lines per inch. For example, 60 mesh means there are 60 diamond patterns per inch on the paper. In practical applications, the industry may also use “grids/cm²” to represent surface density.

The density (apparent density) of the adhesive coating on DDP plays a direct role in determining its electrical and mechanical properties. The key effects include:

Diamond density influences the dielectric performance of the material. A higher-density insulating paper can more effectively isolate electric fields, reduce the risk of corona discharge and partial discharge, and thereby improve the insulation reliability of oil-immersed power transformers.

The compactness (density) of the base material directly affects the compressive strength and deformation resistance of the paper. For instance, insulating paper with a density ranging from 0.85 to 1.10 g/cm³ can meet the mechanical strength requirements for interlayer insulation in oil-immersed transformers.

Diamond density also affects the oil absorption capacity of the material. Insulating paper with oil absorption ≥20% can better absorb transformer oil, enhancing heat dissipation. However, operators must balance oil uptake with gas release to avoid air gaps that may lead to partial discharges.

For thin base materials (0.08–0.13 mm): Recommended diamond spacing is 1.5–2.0 mm, with single-sided resin coating thickness of 5–10 μm. This ensures a balance between flexibility and insulation performance.

For thick base materials (0.18–0.38 mm): Diamond spacing can be increased to 2.0–3.0 mm, with resin thickness of 10–15 μm per side, to enhance mechanical support.

For inter-turn insulation in oil-immersed transformers: High-density diamonds (1.5–2.0 mm spacing) are preferred to improve voltage withstand capability.

For interlayer insulation in distribution transformers: Medium-density diamonds (2.0–2.5 mm spacing) are suitable to balance cost and performance.

For high-voltage/ultra-high-voltage equipment: Customized ultra-high-density diamonds (spacing ≤1.0 mm) should be used, along with Class H insulation systems (temperature resistance up to 180°C).

For high-altitude applications: Increase the DDP diamond density by 10%–15% to compensate for reduced air density and maintain insulation performance.

For high-humidity environments: Choose DDP with hydrophobic resin formulations, and reduce diamond density by 5%–10% to minimize moisture absorption risk.

Q: How can I determine if the current diamond density is appropriate?

A: Operators can assess the suitability of DDP diamond density by measuring the diameter of the resin dots, conducting shear strength tests, and performing microscopic inspections.

Q: Are density standards consistent across different brands?

A: There may be a measurement variation of approximately ±5 mesh between different brands of DDP diamond dotted paper. It is recommended to use products from the same supplier to ensure consistency.

Q: What should I do if the wrong density is selected?

A: If an incorrect DDP diamond density is chosen, partial compensation can be made by adjusting the dotting parameters. However, the fundamental solution is to replace the paper with one of the appropriate density.

Q: How should diamond density be adjusted for high-temperature environments?

A: When using DDP in high-temperature conditions, it is generally recommended to increase the diamond density by 3–7 mesh for every 25°C rise in temperature. The exact adjustment should be verified through testing.

Selecting the optimal diamond density for DDP diamond dotted paper requires a comprehensive consideration of factors such as base material thickness, application scenarios, and environmental conditions. We hope this guide provides valuable reference for choosing the appropriate diamond density in practical applications, enabling DDP to better serve the power equipment industry.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……