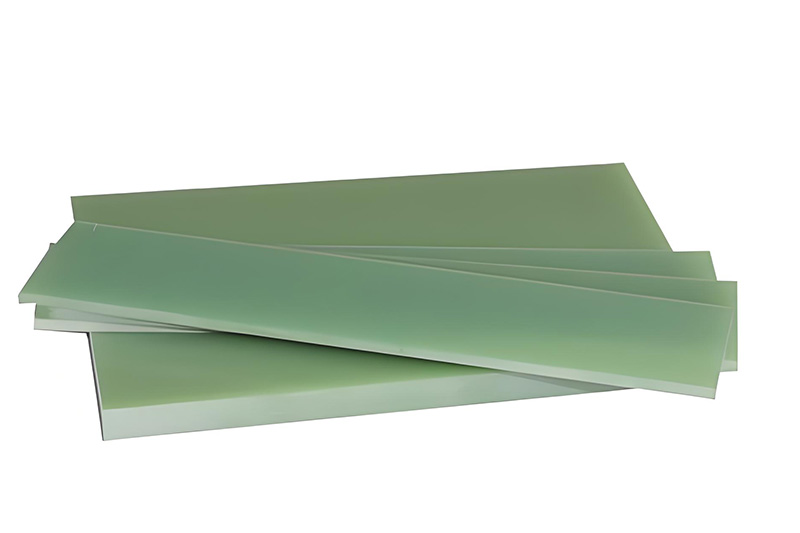

In the electrical and mechanical fields, material performance directly impacts equipment safety, reliability, and cost-effectiveness. As a high-performance insulating material, G10 epoxy sheet is widely used across many industries due to its outstanding electrical insulation properties, excellent mechanical strength, superior weather and chemical resistance, as well as its exceptional machinability and environmental friendliness. Below is an in-depth analysis of the key advantages of G10 epoxy sheet from multiple dimensions.

One of the most prominent advantages of G10 epoxy sheet lies in its exceptionally high dielectric strength, with a breakdown voltage far exceeding that of conventional insulation materials. This feature allows it to effectively isolate high voltage, significantly reducing the risks of arc discharge and short circuits. In critical applications such as high-voltage switchgear, transformer insulation components, and busbar support structures, G10 epoxy sheet ensures the safe and stable operation of electrical systems.

In high-frequency circuit applications, signal attenuation and energy loss are critical challenges. Thanks to its low dielectric loss, G10 epoxy sheet effectively preserves signal integrity. In demanding fields such as communication equipment, high-frequency circuit boards, and RF modules, using G10 epoxy sheet can significantly reduce transmission losses, enhancing overall device performance and communication quality.

G10 epoxy sheet exhibits outstanding flexural strength, tensile strength, and hardness, allowing it to withstand significant mechanical stress and effectively resist damage caused by vibration or impact. It demonstrates exceptional reliability in the manufacturing of components that bear mechanical loads, such as motor insulation frameworks, circuit breaker operating mechanisms, and mechanical support structures. Compared to traditional paper-based or plastic insulating materials, G10 epoxy sheet offers higher mechanical strength and a longer service life, greatly enhancing equipment durability.

Another key mechanical advantage of G10 epoxy sheet is its excellent dimensional stability. Even under fluctuating temperature and humidity conditions, it experiences minimal dimensional changes, ensuring consistent insulation performance. This helps to avoid issues such as cracking or deformation caused by thermal expansion and contraction. As a result, G10 epoxy sheet performs exceptionally well in extreme environments like outdoor substations and industrial furnace electrical systems, maintaining normal operation even under harsh conditions.

G10 epoxy sheet can operate stably over a wide temperature range, maintaining performance in both high- and low-temperature environments. Whether meeting the high-temperature demands of EV battery packs or the low-temperature requirements of aerospace electrical systems, G10 epoxy sheet offers ideal adaptability. Compared to conventional plastic materials, it provides better thermal resistance and lower risk of thermal aging, significantly broadening its application scope.

In corrosive environments such as chemical processing equipment, offshore electrical systems, and wastewater treatment facilities, G10 epoxy sheet demonstrates strong resistance to acids, alkalis, oils, and organic solvents. This enables it to maintain stable performance in harsh chemical settings, effectively extending equipment lifespan and reducing maintenance costs.

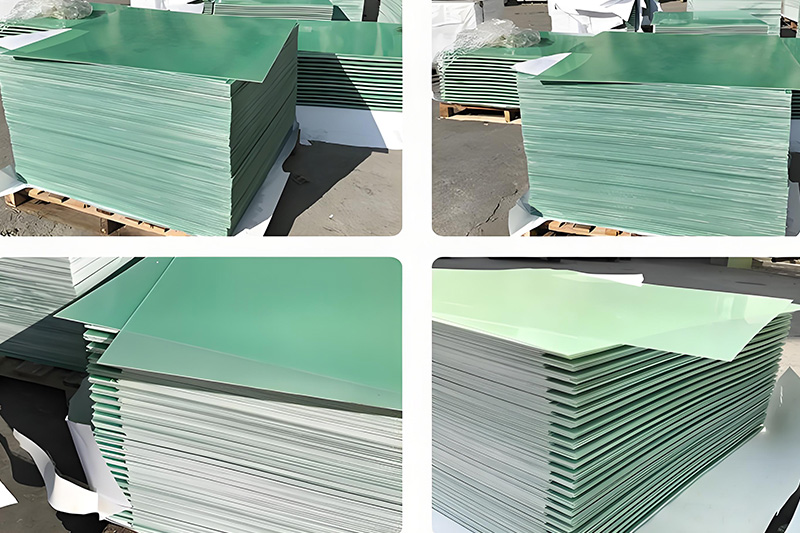

G10 epoxy sheet offers excellent machinability and can be processed into complex shapes through mechanical machining, hot pressing, and other methods, meeting the customization needs of various industries. In the manufacturing of irregular insulation components, precision molds, and custom brackets, G10 epoxy sheet provides higher processing efficiency and lower scrap rates compared to ceramic or metal materials. This not only improves production efficiency but also reduces manufacturing costs.

The long service life and low maintenance requirements of G10 epoxy sheet are key indicators of its economic value. In applications such as rail transit traction systems, industrial automation equipment, and long-running high-voltage electrical systems, the initial purchase cost of G10 may be relatively higher, but its low maintenance needs and reduced failure rates result in lower total lifecycle costs.

G10 epoxy sheet complies strictly with environmental standards. It is halogen-free and asbestos-free, and does not release toxic gases when burned. These features make it a preferred material in fields with stringent environmental requirements such as medical equipment, data centers, and green buildings, providing companies with a compliant and socially responsible material choice.

Recyclability is another major environmental advantage of G10 epoxy sheet. It can be reclaimed through physical or chemical processes, significantly reducing resource waste and aligning with the principles of a circular economy. Against the backdrop of global carbon neutrality initiatives, using G10 epoxy sheet not only helps companies meet carbon reduction goals but also enhances brand image and strengthens market competitiveness.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……