In the process of modern industrial development, the performance and environmental properties of electrical insulation materials are crucial. As an outstanding representative of high-performance electrical insulation materials, G10 fiber sheet occupies an important position in high-end fields such as electronics, aerospace, and military industry with its excellent mechanical strength, heat resistance and insulation performance. With the increasingly stringent global environmental protection standards, its advantages in environmental protection characteristics and sustainable development are becoming the focus of industry attention.

G10 fiber sheet is made of alkali-free glass fiber cloth and epoxy resin. It strictly follows environmental protection standards in the selection of raw materials and does not contain halogen elements such as chlorine and bromine. This makes it perfectly meet the requirements of the EU RoHS environmental protection directive. Under extreme combustion conditions, G10 fiber sheet will not release highly toxic gases such as dioxins, effectively avoiding potential threats to the ecological environment and human health, and highlighting the essential attributes of green materials.

The curing system of G10 fiber sheet does not contain harmful heavy metal components, which reduces the toxicity risk from the source. After the product life cycle, some materials can be recycled and reused through scientific treatment methods such as physical crushing or chemical degradation. This greatly reduces the pollution of solid waste to the environment and plays an important role in resource recycling.

· Environmentally friendly raw materials and processes: In the production process, manufacturers actively adopt environmentally friendly raw materials and advanced production processes. The use of epoxy resin with low volatile organic compounds (VOC) significantly reduces the emission of harmful gases in the production process, and practices the concept of green manufacturing from the source of production.

· Durability and stability: With its excellent durability and stability, G10 fiber sheet has a service life far exceeding that of ordinary materials. This feature effectively reduces the frequency of material replacement, greatly reduces resource consumption, and meets the requirements of circular economic development.

· Energy-saving effect: In the application of electronic equipment, the excellent insulation performance of G10 fiber sheet can significantly improve the energy efficiency of equipment and reduce energy loss. This energy-saving effect not only complies with the green environmental protection concept advocated globally, but also brings substantial reduction in operating costs for enterprises, achieving a win-win situation in economic and environmental benefits.

G10 fiber sheet has extremely high insulation resistance and breakdown voltage. Even in high voltage environment, it can still maintain stable and reliable electrical performance, building a solid barrier for the safe and stable operation of electrical equipment. Its low relative dielectric constant and extremely small dielectric loss factor make it an ideal choice for insulation materials for high-frequency circuits and precision electronic equipment.

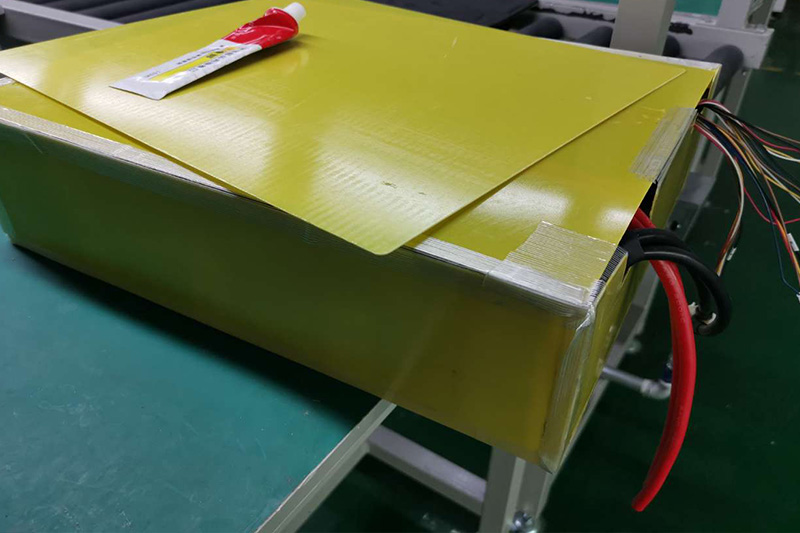

G10 fiber sheet has excellent mechanical properties and has excellent bending strength, compression strength and impact strength. It can easily cope with mechanical vibration and shock in complex environments, providing reliable protection for electrical components with extremely high requirements for mechanical stability.

G10 fiber sheet has good heat resistance and can work stably for a long time in a high temperature environment of 180℃, and can withstand extreme high temperatures of 288℃ in a short time. In a high temperature environment, it can still maintain excellent mechanical and electrical properties, and is suitable for electrical equipment under various high temperature conditions.

G10 fiber sheet has a flame retardant rating of UL94-V0 and has the characteristic of self-extinguishing when away from fire. In the case of fire hazards, it can effectively curb the spread of fire and provide reliable protection for the safety of equipment and personnel.

G10 fiber sheet has excellent acid and alkali corrosion resistance and extremely low water absorption. Even if used for a long time in a humid or chemically corrosive environment, it can still maintain stable performance, which greatly broadens its application range.

G10 fiber sheet has an extremely low thermal expansion coefficient and small dimensional changes during temperature changes. This feature enables it to meet the needs of electrical components with extremely high dimensional accuracy and ensure the high reliability of equipment operation.

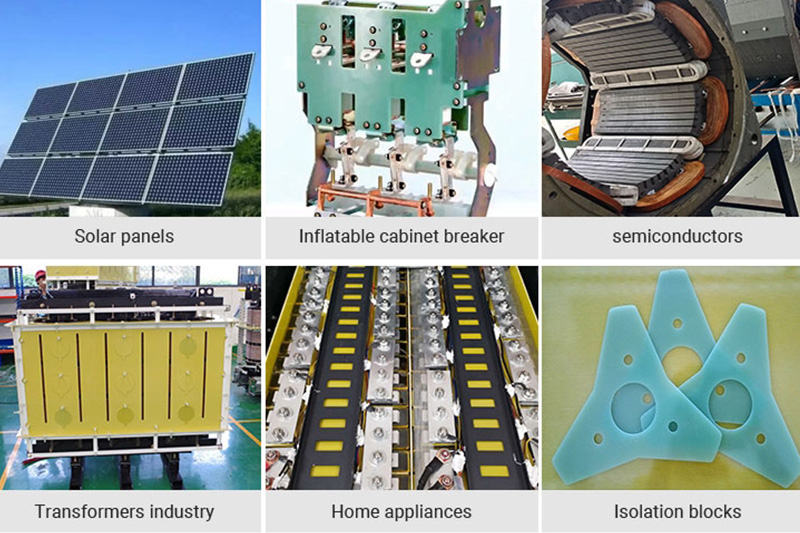

G10 fiber sheet has good mechanical processing performance and can be made into various complex shapes through a variety of processing methods, fully meeting the personalized design needs of different electrical equipment and effectively improving production efficiency.

With its significant environmental advantages and excellent performance, G10 fiber sheet has set an industry benchmark in the field of electrical insulation. Its excellent performance in halogen-free design, long life use and environmental compliance makes it an ideal choice for green manufacturing. Although achieving complete biodegradability is still a challenge facing the industry, with the continuous innovation of material science and continuous improvement of production processes, the sustainable development performance of G10 fiber sheet will continue to improve. In practical applications, it is recommended to give priority to products that have passed authoritative environmental certifications such as UL Eco Label, and comprehensively consider performance and ecological impact according to specific needs to achieve the best application effect.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……