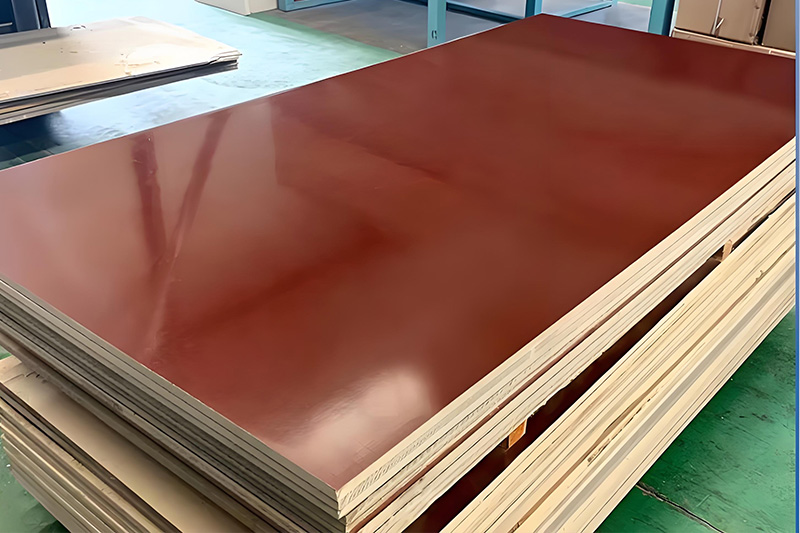

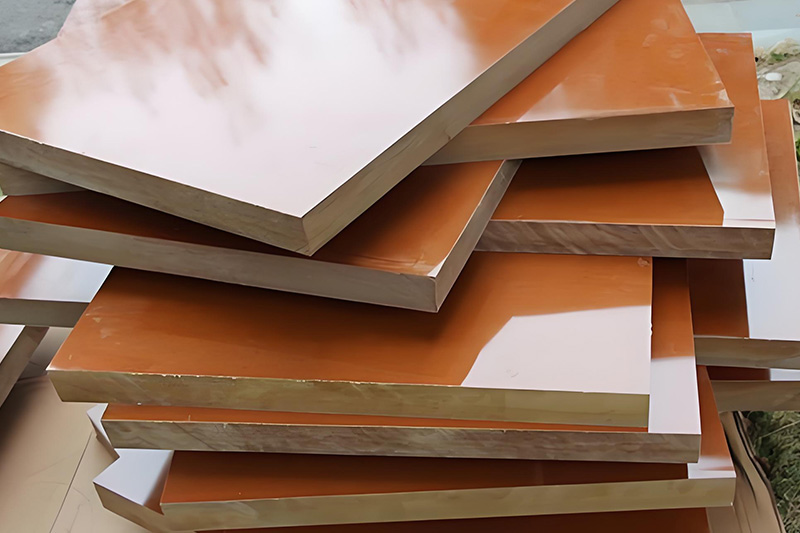

Phenolic cloth sheet, as a high-performance thermosetting laminate, is produced by thoroughly impregnating cotton fabric with phenolic resin and compressing it under high temperature and pressure. Compared to paper-based phenolic laminates, cloth-based phenolic sheets offer superior impact resistance and excellent wear resistance, making them ideal for machining into components that must withstand mechanical stress and friction. They also perform reliably in transformer oil environments, showcasing exceptional environmental adaptability. With outstanding dimensional stability, thermal deformation resistance, and machinability, phenolic cloth sheet is widely favored in the electrical and mechanical industries.

Phenolic cloth sheet is a high-performance composite material made from a deep integration of cotton fabric and phenolic resin, processed through drying and hot-pressing. It offers several distinctive properties:

Under normal operating conditions, phenolic cloth sheet exhibits excellent electrical insulation properties. Its thermal class typically reaches Class E, providing reliable insulation for structural components in motors and electrical devices.

The material has exceptional mechanical strength and performs well under various mechanical stresses, maintaining stable characteristics in complex mechanical environments.

Thanks to its unique material composition, phenolic cloth sheet can operate stably in transformer oil, ensuring the long-term reliable performance of the equipment.

Phenolic cloth sheet is highly machinable, allowing for operations such as sawing, drilling, turning, milling, and planing. Post-processing issues such as cracking or edge chipping are rare, significantly improving production efficiency and final product quality.

Phenolic cotton cloth laminates are widely used in the manufacturing of insulation components for low-voltage motors and electrical appliances, such as washers, slot wedges, and screws. Their excellent electrical properties and mechanical strength provide a solid foundation for the safe and stable operation of electrical equipment.

In transformer insulation structures, phenolic cotton cloth laminates are a preferred material for components like insulation pads and partition boards due to their outstanding oil resistance and electrical insulation performance. These properties meet the stringent requirements for long-term stable operation of transformers.

In the electronics industry, phenolic cotton cloth laminates are used in the production of insulating switches, variable resistors, PCB drilling backing boards, distribution box jigs, and mold clamping plates. Their non-absorbent, non-conductive, and high-temperature-resistant characteristics make them an ideal choice for insulation and protection in electronic products.

Phenolic cloth sheets also perform exceptionally well in applications involving mechanical molds, forming machines, drilling machine work surfaces, and grinding pads. Thanks to their high mechanical strength and excellent wear resistance, they significantly extend the service life of molds and fixtures while reducing equipment maintenance costs.

With their versatility and high reliability, phenolic cotton cloth laminates shine in the field of industrial insulation. Whether used to build motor insulation structures, produce wear-resistant mechanical parts, or support control cabinets in harsh environments, they consistently deliver outstanding performance. For companies and projects seeking stable performance, ease of processing, and cost-effectiveness in industrial insulation materials, phenolic cloth sheets are undoubtedly a highly valuable and preferred solution.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……