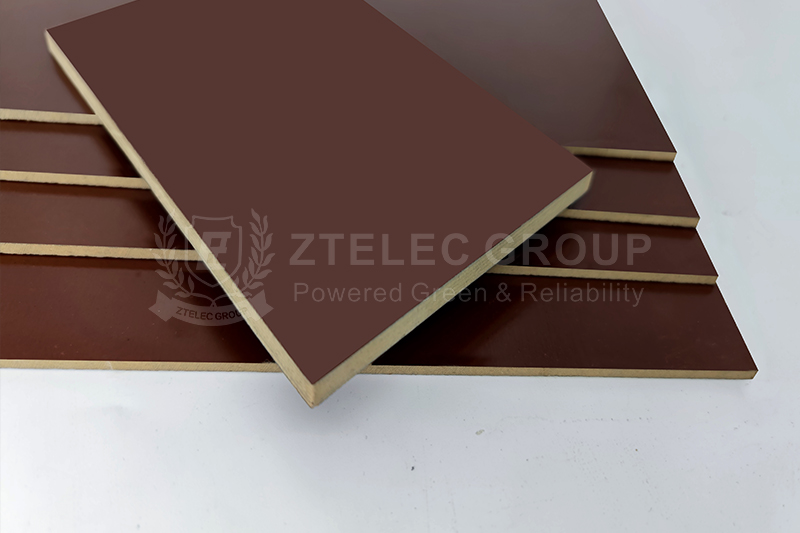

In modern industrial production and daily life, insulation materials are crucial. It ensures the safe operation of electrical equipment and maintains the stability of production and life. Phenolic board is a commonly used insulating material. It has attracted the attention of many industries due to its excellent performance and wide application. Next, I will introduce the characteristics, advantages and practical applications of phenolic board in detail.

The molecular structure of phenolic board is very stable. This makes it have a strong ability to prevent the passage of current and can provide reliable insulation protection in electrical equipment. Whether it is high-voltage electrical appliances or precision electronic instruments, the use of phenolic board can ensure that the current flows in the established circuit, effectively reduce the risks of leakage, short circuit, etc., and ensure the safe operation of the electrical system.

The physical and chemical properties of phenolic board remain stable in high temperature environment. Under normal circumstances, it can be used for a long time in an environment of 120℃. In a short period of time, it can even withstand high temperatures of more than 200℃. In high-temperature industrial fields such as metallurgy, chemical industry, and electric power, the temperature of equipment is extremely high when it is running. Phenolic board can resist high temperature invasion and avoid deformation and decomposition, thereby ensuring the normal operation of the equipment and extending the service life of the equipment.

Phenolic board is a flame-retardant material. When it encounters an open flame, a carbonized layer will quickly form on its surface. This carbonized layer can effectively block the spread of flames and heat transfer. Not only that, phenolic board produces very little smoke when burning, and does not release toxic and harmful gases. For this reason, phenolic board has become an ideal choice in fields with high requirements for fire safety, such as construction and transportation. It can effectively ensure the safety of personnel and reduce the harm caused by fire.

Phenolic board has good compression, tension and impact resistance. It can withstand certain external forces and is not prone to deformation or damage during processing and use. This feature enables it to meet the mechanical requirements in different scenarios. For example, when manufacturing mechanical parts that are subject to greater pressure, phenolic board can be used as a structural material to provide reliable support and protection for the parts to ensure the normal operation of the machine.

Phenolic board has good tolerance to a variety of chemical substances such as acids, alkalis, and salts. In industries with corrosive environments such as chemical production and sewage treatment, it is often used to make storage containers, pipes, equipment linings and other parts. The use of phenolic boards can effectively prevent chemical substances from corroding materials, extend the service life of equipment, reduce maintenance costs, and ensure the safety and stability of the production process.

The production cost of phenolic board is relatively low. Its raw materials are widely available, easy to obtain, and the production process is relatively mature. Under the premise of ensuring good performance, the price of phenolic board is more competitive. For many industries and projects that focus on cost control, phenolic board can not only meet performance requirements but also control costs. So it is an ideal choice.

The processing methods of phenolic board are rich and varied. It can be made into parts of various shapes and sizes through cutting, drilling, grinding, stamping, etc. to meet different usage requirements. In addition, its appearance quality and performance can be further improved through surface treatment methods such as spraying and electroplating. In this way, phenolic board can meet functional requirements and meet certain aesthetic requirements, and is suitable for various complex engineering and product manufacturing.

As people’s environmental awareness continues to improve, the requirements for the environmental performance of materials are becoming more and more stringent. Phenolic board has significant advantages in this regard. It will not produce substances harmful to the environment during production and use. Most of its raw materials are natural or synthetic polymer materials, which can be recycled after being discarded to reduce pollution to the environment. At the same time, the flame retardant properties and low smoke generation characteristics of phenolic boards also help reduce the damage to the environment when a fire occurs, which fully meets the requirements of modern society for environmentally friendly materials.

In the electrical industry, phenolic board is an indispensable insulating material. It is widely used in various electrical equipment, such as transformers, motors, switches, sockets, etc.

In transformers, phenolic board is used to make insulating gaskets, insulating sleeves and other components to ensure electrical insulation between the internal components of the transformer and prevent short circuit faults.

In motors, phenolic board can be used as slot wedges and insulating brackets to fix windings, insulate and support, and ensure the normal operation and safety performance of motors.

In addition, phenolic board is also often used to make the outer shell of electrical equipment, which can provide good insulation protection and have a certain mechanical strength to protect internal electrical components from damage by external factors.

In the field of transportation, phenolic board also plays an important role. In automobile manufacturing, phenolic board can be used to make automobile interior parts, such as dashboards, door interior panels, etc. Because it has good flame retardancy, low smoke and environmental protection performance, it can effectively improve the safety and comfort of automobile interiors, while reducing the release of odors and harmful gases in the car.

Phenolic board has been widely used in many fields due to its excellent performance and significant advantages. With the continuous advancement of science and technology and the continuous development of the industry, the performance of phenolic board will be continuously optimized and improved, and the scope of application will be further expanded. And it will provide more reliable and high-quality material support for the development of various fields.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……