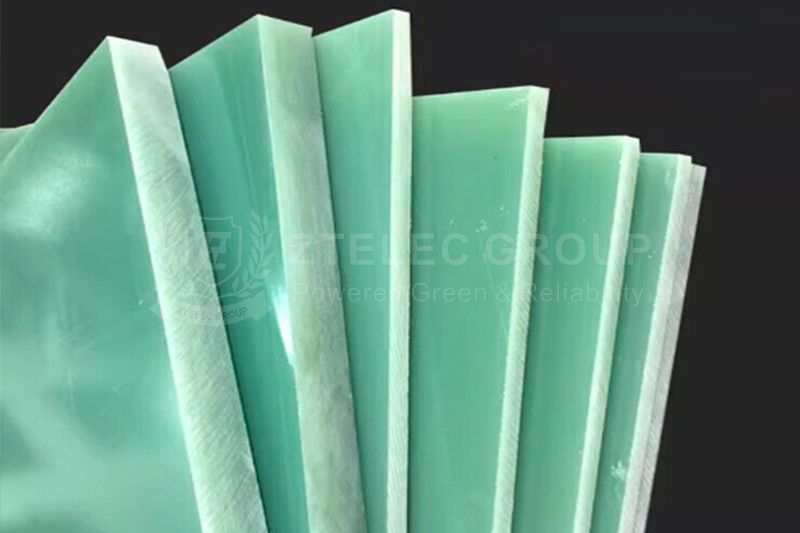

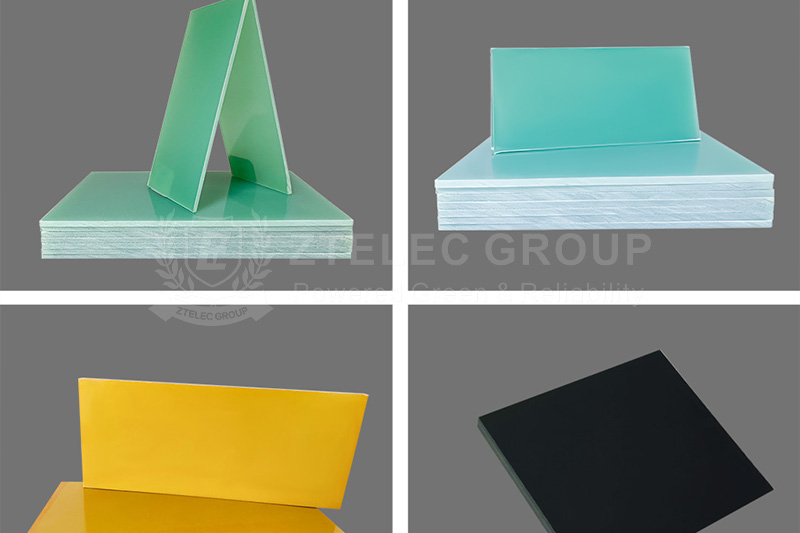

In the field of power electronics, the performance of materials directly determines the performance of the equipment. FR4 materials have become the first choice in many power electronics application scenarios due to their excellent comprehensive performance. Next, we will introduce you to the eight typical applications of FR4 materials in the field of power electronics in detail.

In various power electronic equipment, printed circuit boards (PCBs) are responsible for connecting and supporting electronic components. And FR4 is one of the most commonly used materials for making PCBs. It has good electrical properties and can effectively isolate different circuits on the circuit board to prevent interference and short circuits, ensuring stable signal transmission. Thanks to glass fiber reinforcement, FR4 materials have high mechanical strength, excellent bending and impact resistance, and can withstand the stress caused by complex circuit layouts. In addition, FR4 materials have good processing performance, and operations such as drilling, cutting, and bending can be easily completed. It is particularly suitable for manufacturing various complex multilayer board structures. Therefore, FR4 materials can be seen in the PCB manufacturing of computers, communication equipment, consumer electronics, etc.

In the field of industrial automation, the operation of equipment is inseparable from the insulation components of various control modules. These components must have good electrical performance and stability. FR4 material has high dielectric strength and corona resistance, which can ensure the reliable operation of equipment in complex electromagnetic environments. It is an ideal choice for manufacturing insulation components.

Inside motors and electrical equipment, FR4 materials are widely used to manufacture insulation structural components, such as various switch FPC reinforcements, electrical insulation components, etc. With high dielectric strength and corona resistance, FR4 materials can effectively prevent current breakdown and corona effects, ensuring stable operation of equipment under high voltage environments. At the same time, its good high temperature resistance and corrosion resistance also allow the equipment to maintain stable performance in harsh environments.

The function of the inverter is to convert direct current into alternating current, which is crucial in the field of power electronics. Its substrate is often made of FR4 material. The good electrical insulation performance of FR4 material can effectively isolate different circuits and avoid short circuit problems. Moreover, its heat resistance can meet the heat requirements generated by the inverter during operation, ensuring the stable operation of the inverter. FR4 material is widely used in photovoltaic inverters and other equipment.

In high-voltage cable systems, FR4 epoxy tubes are often used as cable protection tubes. It can effectively resist damage to cables from external environments such as moisture and corrosion. And because of its high dielectric strength and corona resistance, it can also ensure the safe operation of cables under high-voltage environments. In addition, FR4 materials have certain flame retardancy, which can reduce the risk of fire and further improve the safety of cable systems.

Various types of sensors are widely used in power electronic systems, and insulation components made of FR4 materials are an important part of sensors. The stable electrical insulation performance of FR4 materials can prevent sensor signals from being interfered with, ensuring that sensors accurately sense and transmit data. At the same time, its good mechanical properties also ensure the structural stability of insulation components in different environments.

Switching power supplies are very common in power electronic equipment. FR4 materials are used to make PCBs and some insulation components of switching power supplies. It has moderate cost and is suitable for large-scale production. And the electrical and mechanical properties of FR4 materials can meet the requirements of switching power supplies for circuit boards, ensuring that the power supply can efficiently and stably supply power to other devices.

Uninterruptible power supply (UPS) is used to provide emergency power to equipment during power outages. FR4 material is used in PCB manufacturing and insulation components of UPS. Its flame retardant properties make UPS safer during use, and it can quickly extinguish itself when encountering a fire source, reducing the risk of fire. With excellent comprehensive performance, FR4 material ensures the reliable operation of UPS in various environments and protects the power supply of important equipment.

From basic PCB manufacturing to complex high-frequency equipment, FR4 material plays an indispensable role in the field of power electronics with its excellent electrical properties, mechanical properties, flame retardancy, good processability and cost-effectiveness, and also provides strong support for the continuous development of power electronics technology.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……