In high-end industries such as power, electronics, and aerospace, FR5 epoxy boards have become an indispensable material due to their excellent heat resistance and mechanical strength. Choosing a high-quality FR5 epoxy board supplier not only affects product performance but also directly impacts project timelines and cost control. This article analyzes the key evaluation criteria for selecting quality FR5 epoxy board suppliers from three core aspects: certifications, pricing strategy, and lead time management.

Certifications serve as a critical measure of both product quality and the supplier’s production management standards. Internationally recognized certifications are strong evidence of a company’s compliance with industry norms.

The UL 94 V-0 rating is a key indicator of the fire safety performance of FR5 epoxy boards. Products with this certification can self-extinguish within a specified time under standardized testing conditions, significantly reducing fire risks. In today’s highly integrated electronic environments—such as data center server cabinets—FR5 epoxy boards with UL 94 V-0 certification can effectively prevent the spread of fire in the event of a short circuit, safeguarding both equipment and personnel.

RoHS restricts the use of hazardous substances such as lead and mercury in electrical and electronic equipment, while REACH regulates the registration, evaluation, and authorization of chemicals. As global environmental awareness continues to rise, using non-compliant materials not only exposes companies to legal risks but also damages brand reputation. Choosing suppliers certified with both RoHS and REACH ensures compliance with international market entry requirements and aligns with corporate sustainability strategies.

ISO 9001 is applicable to all types of organizations and emphasizes continuous improvement of product and service quality through robust quality management systems. IATF 16949, designed for the automotive industry, imposes stricter requirements on process control and product traceability. These certifications reflect a supplier’s rigorous control over the entire production process—from raw material sourcing to final product delivery—ensuring consistent product quality and adherence to industry standards.

When evaluating the pricing of FR5 epoxy board suppliers, it’s important to consider more than just the unit cost. A comprehensive assessment should include factors such as material composition, customization capability, and payment terms to achieve the optimal balance between cost and value.

The density of the glass cloth determines the mechanical strength of the board, while the resin ratio affects its heat resistance and insulation performance. High-quality suppliers will select appropriate raw material specifications based on customer requirements, aiming to meet performance needs while controlling costs. For example, in general consumer electronic devices, FR5 epoxy boards made with medium-density glass cloth and a standard resin ratio are typically sufficient—there’s no need to use premium-grade materials that would unnecessarily increase costs.

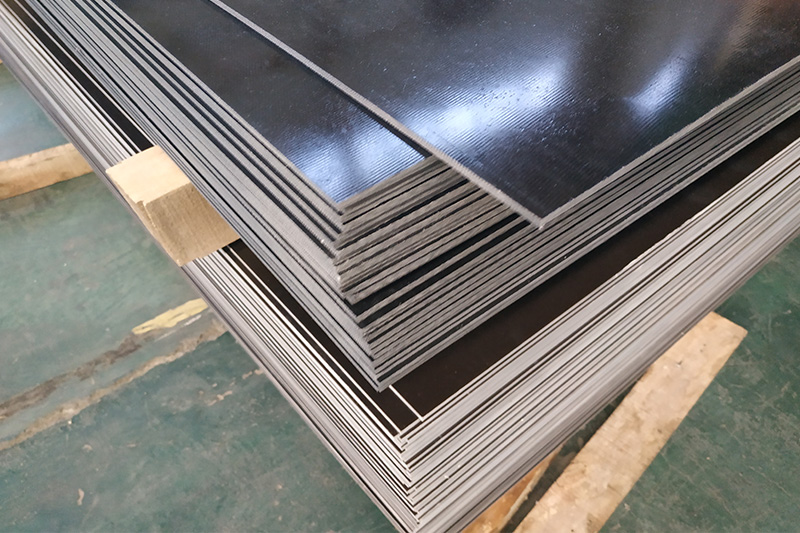

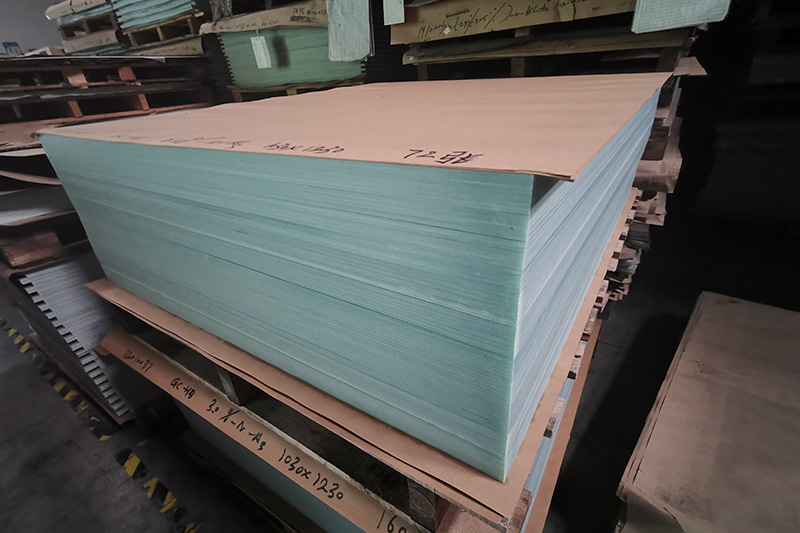

Different industries and projects have varying requirements for the thickness, dimensions, and color of FR5 epoxy boards. Suppliers with strong customization capabilities can quickly respond to customer needs and offer tailored solutions. In the aerospace sector, epoxy boards often need to be customized in special sizes and shapes to fit complex structures. In the consumer electronics industry, specific color requirements may be necessary. The greater a supplier’s ability to customize, the more value they can create for their customers.

Reasonable credit terms can ease financial pressure for enterprises, while flexible exchange rate strategies help mitigate currency fluctuation risks. Some suppliers offer credit periods based on order volume and customer credit standing. In international procurement, certain suppliers also offer foreign exchange locking mechanisms to help clients avoid currency risks. These details should not be overlooked when evaluating a supplier’s pricing strategy.

In today’s highly competitive market, project timelines are critical, and a supplier’s delivery time management capabilities directly affect project progress. A reliable supplier should have sufficient inventory, strong production capacity, and efficient logistics coordination.

Adequate stock of standard materials is essential for responding quickly to small-batch orders. In scenarios such as electronics repair, customers may urgently need a small quantity of FR5 epoxy boards for component replacement. In such cases, a supplier’s ability to provide in-stock materials can significantly shorten delivery times.

Strong production capacity is the guarantee to meet the demand for large quantities with short delivery time. In urgent projects such as the expansion of new energy vehicle production lines, the demand for FR5 epoxy boards has surged. Suppliers with advanced equipment and reasonable production scheduling can complete orders on time while ensuring quality.

Efficient logistics collaboration is the key to the smooth delivery of products. High-quality suppliers and reliable logistics partners have long-term cooperation, and can provide safe and efficient solutions for both domestic and international transportation. In international procurement, suppliers should also have customs clearance service capabilities to reduce the detention time of goods in customs.

Selecting high-quality FR5 epoxy board suppliers is a systematic project. Certification qualifications are the bottom line of quality, price strategies reflect value creation, and delivery management ensures the stability of the supply chain. When making actual choices, the corporate procurement team can comprehensively evaluate suppliers through field visits, sample testing, customer word-of-mouth surveys, etc., select strategic partners for long-term cooperation, and help companies stand out in market competition.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……