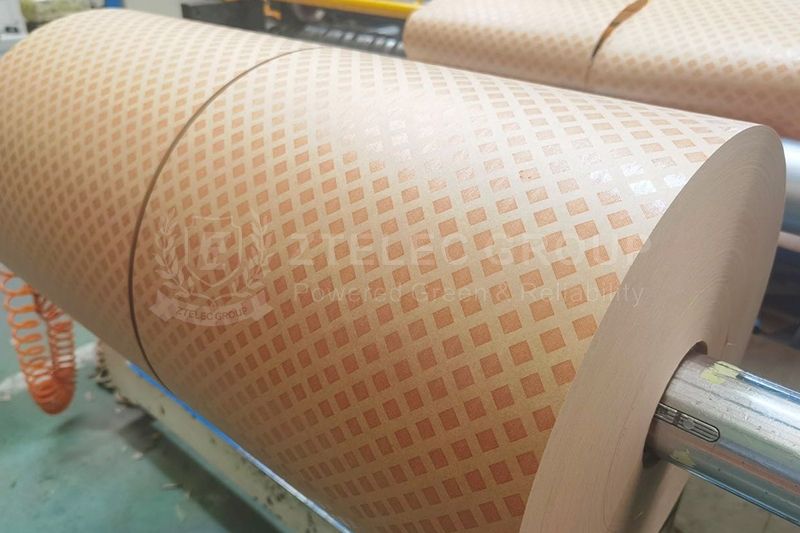

DDP Diamond Pattern Paper is a specialized insulating material developed specifically for oil-immersed power transformers. Its surface is evenly coated with diamond-shaped epoxy resin dots, playing a critical role in both bonding and insulation during transformer manufacturing.

DDP diamond pattern paper typically uses high-density insulating paper as its base, such as cable paper or Nomex paper.

Modified epoxy resin will be accurately coated on the surface of the substrate to form a regular diamond dot pattern. In addition, the dot density can also be flexibly adjusted according to actual needs.

During the drying and baking process of transformer assembly, the epoxy resin dots melt under heat and subsequently cure, firmly bonding the insulating layers together.

Thickness: Its thickness specifications cover a variety of options such as 0.13mm, 0.18mm, and 0.25mm.

Width: Standard widths are 1020mm, 1220mm, etc., and can also be customized according to the specific needs of customers.

Dot Density: The density can be adjusted according to the design requirements of the transformer, such as the common 9.5×9.5mm and other specifications.

DDP Diamond Pattern Paper is widely used in oil-immersed transformers, primarily in the following areas:

Interlayer Insulation: It is used between high and low-voltage windings to ensure safe electrical isolation.

Turn-to-Turn Insulation: DDP insulation paper is suitable for bonding turns in foil-wound coils, helping maintain the structural integrity of the windings.

Amorphous Alloy Transformers: DDP paper enhances the fixation between the core and windings, ultimately improving the overall performance of the transformer.

DDP Diamond Pattern Paper features a diamond grid formed by modified epoxy resin coating. During the drying process of transformer coils, the resin melts at specific temperatures, tightly bonding adjacent layers. Once cured, it forms a stable and integrated structure. This strong adhesive strength effectively resists displacement of the windings during short circuits, ensuring the transformer maintains long-term mechanical and electrical stability.

Thanks to its dotted resin distribution, DDP paper allows transformer oil to fully penetrate the insulation layers. This structure also facilitates gas release, helping to prevent corona discharge and partial discharge phenomena. As a result, the safety and reliability of the insulation system are significantly enhanced.

DDP diamond dotted paper is particularly suitable for advanced processes such as amorphous alloy transformers and foil winding transformers (such as copper foil/aluminum foil windings). In these processes, its excellent bonding strength and insulation performance are indispensable. In contrast, low-quality alternatives may cause many serious problems, while high-quality DDP diamond pattern paper can fully meet these stringent process requirements.

Compared with the traditional varnishing process, DDP diamond pattern paper does not require additional varnishing treatment. In this way, the use of toxic solvents is avoided and energy consumption is reduced. At the same time, this also shortens the production cycle, and ultimately effectively reduces the overall production cost.

DDP diamond pattern paper can be immersed in hot oil environment for a long time and can resist the effects of thermal aging. During use, it will not cause impurities to fall off and pollute the transformer oil. Its service life is highly matched with the transformer equipment, which effectively guarantees the reliability of the long-term operation of the transformer.

DDP diamond pattern paper has high tensile strength and tear strength. Therefore, it can withstand the mechanical stress generated during the operation of the transformer, such as axial short-circuit stress, thereby significantly improving the transformer’s impact resistance and further extending its overall service life.

DDP diamond pattern paper, with its diamond-shaped adhesive pattern, integrates both insulation and bonding functions, making it a high-performance insulating material. It is widely used in oil-immersed transformers, effectively enhancing the mechanical strength, short-circuit resistance, and long-term operational reliability of the transformers. Compared to traditional varnishing processes, DDP diamond dotted paper is more environmentally friendly and efficient, fully meeting the manufacturing requirements of modern transformers such as amorphous alloy transformers and foil-wound transformers.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……