G11 fiberglass sheet is widely used in the electronics industry and other fields, and its price is affected by many factors. Understanding these factors is crucial for enterprises to rationally plan costs and budgets. Below, we will conduct a detailed analysis from two aspects: core influencing factors, market and supply chain factors.

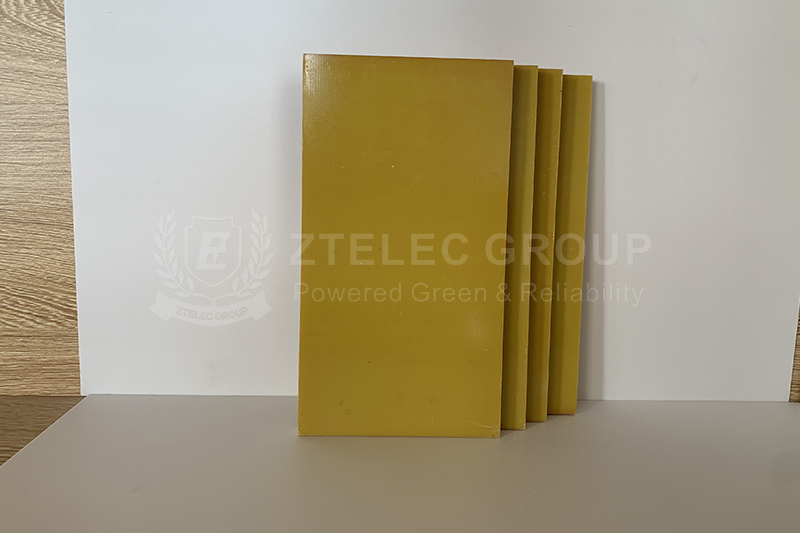

Raw material cost is the basic factor that determines the price of G11 fiberglass sheet. First, the type of resin has a significant impact on the price. There are many types of epoxy resins, including ordinary epoxy resins, high Tg epoxy resins, and halogen-free epoxy resins, and the prices of different types vary greatly. Among them, high-performance resins have higher production costs due to their special properties. Secondly, the grade of fiberglass cloth is also a key factor. Fiberglass cloth has various thickness specifications, such as 106, 1080, 2116, etc., and its weaving density is also different. Both thickness and weaving density affect the price. High-precision fiberglass cloth has a higher cost due to the difficulty of production. In addition, the use of additives will also increase costs. When the product needs to have special properties such as flame retardant and UV resistance, it is necessary to add special additives such as flame retardants and UV resistance, which will undoubtedly increase the production cost.

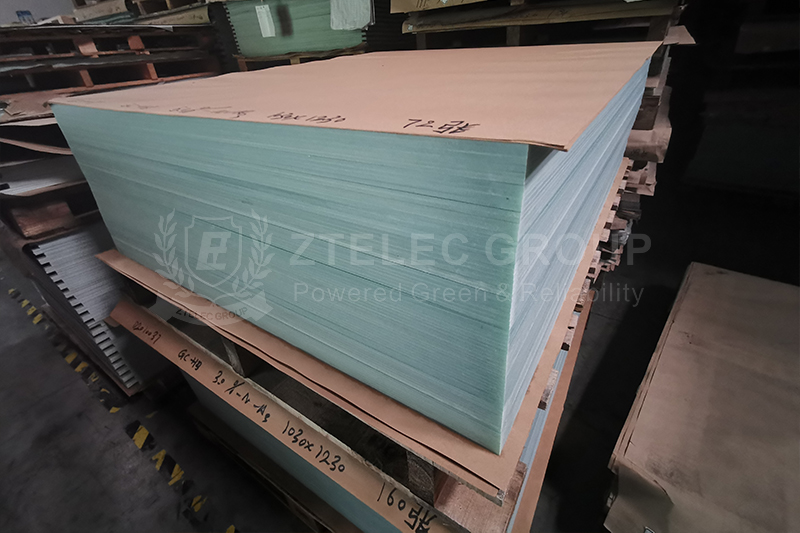

The specifications of G11 fiberglass sheet also have an important impact on the price. In terms of thickness, the common thickness range is between 0.2mm and 3.0mm. However, whether it is a very thick or very thin board, due to the need for special processes in production, its price will be higher than that of regular thickness boards. In terms of size specifications, standard sizes such as 1220mm×2040mm boards are more efficient in production and processing, and the cost performance is relatively good; while customized sizes, especially oversized or special-shaped sheets, require additional cutting processing, so cutting fees will be added, resulting in price increases. For copper clad laminates, the thickness of copper foil is also one of the factors affecting the cost. For example, for copper foils of different thicknesses such as 1oz and 2oz, the thicker the copper layer, the more copper material is used, and the higher the cost.

The complexity and technical requirements of the production process are directly related to the cost of G11 fiberglass sheet. In terms of lamination technology, low-loss boards used in high-frequency and high-voltage environments require a special lamination process to ensure the performance of the board. This makes the production process more complicated and the cost increases accordingly. Surface treatment processes will also increase costs. Different surface treatment methods such as immersion gold, tin spraying, and OSP require additional process steps and materials, thereby increasing production costs. In addition, tolerance control is also an important factor affecting the price. High-precision processing, such as controlling the tolerance to ±0.05mm, is more difficult than ordinary tolerances (±0.1mm) and requires more sophisticated equipment and higher technical levels, so the price is usually 20% – 30% more expensive.

The certification and standards that the product meets will also affect the price of G11 fiberglass sheet. When G11 fiberglass sheet passes UL certification, meets RoHS compliance requirements, or meets military-grade (MIL-SPEC) standards, these certifications will increase the production cost of the product, but at the same time, they also ensure the reliability and safety of the product. In some application scenarios with high requirements for product quality and safety, certified products are more favored by the market.

The size of the purchase volume plays an important role in the price formation of G11 fiberglass sheet. When purchasing in small quantities, such as less than 10 sheets, the unit price may be 30% – 50% higher than that of large-volume purchases (such as more than 100 sheets) because the scale effect of production and transportation cannot be reflected. When signing a long-term contract or annual agreement with a supplier, the company can usually get a certain price discount, because long-term and stable orders help suppliers to arrange production reasonably and reduce costs.

The choice of supplier will also affect the price and quality of G11 fiberglass sheet. Brand manufacturers often have a certain premium in product prices due to their advantages in production technology and quality control, but at the same time they can also ensure the stability of product quality. In contrast, the product prices of small and medium-sized manufacturers are usually lower, but in order to ensure that the product quality meets the requirements, companies need to conduct strict inspections on their products. In terms of origin, the price of imported boards, such as G11 fiberglass sheets produced in the United States and Japan, may be 1.5-2 times that of domestic boards. However, in recent years, the quality of domestic boards has been continuously improved, and the cost-effectiveness advantage has become more and more obvious. Products of domestic manufacturers are also very competitive in the market.

Logistics and tariffs are also important external factors affecting the price of G11 fiberglass sheets. When companies purchase imported materials, they need to fully consider costs such as freight and tariffs. For example, the United States imposes tariffs on Chinese fiberglass sheets, which will undoubtedly increase import costs. In addition, exchange rate fluctuations will also have an impact on prices, because changes in exchange rates will lead to changes in raw materials and transportation costs denominated in different currencies.

The price of G11 fiberglass sheet is affected by multiple factors such as raw material cost, production process, logistics and transportation, market supply and demand, and policy and environmental protection. In the face of cost fluctuations, enterprises can optimize costs and improve price competitiveness through the following strategies:

Optimize supply chain management: Establish long-term and stable cooperative relations with raw material suppliers, and reduce procurement costs through centralized procurement and signing long-term agreements.

Promote technological upgrades: Expand the scale of kilns, introduce intelligent manufacturing technology, improve production efficiency, and reduce energy consumption and production costs per unit product.

Layout location advantages: Build production lines in areas with low energy costs and convenient logistics and transportation to reduce energy and logistics expenditures.

Respond to policy guidance: Increase R&D investment, develop high-end products, actively strive for policy subsidies, and reduce environmental protection costs by optimizing production processes.

By comprehensively applying the above strategies, enterprises can effectively achieve cost optimization in the fierce market competition, improve their own price competitiveness, and thus occupy a favorable position in the G11 fiberglass sheet market.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……