In the development of the power electronics industry, the selection of insulation materials is crucial. It directly affects the performance, operational safety and service life of the equipment. SMC, FR4 epoxy glass cloth laminate, mica, ceramics and electrical boards are widely used insulation materials. They have different characteristics and are suitable for different scenarios. Next, the advantages and disadvantages and typical applications of these materials will be analyzed in detail.

SMC is a composite material composed of unsaturated polyester resin, glass fiber, etc. It is resistant to high temperatures, has high mechanical strength, can withstand large external forces. And it is used as a structural part. In a high-voltage environment, SMC has good arc resistance and can reduce the damage of arc to the material. Through the compression molding process, SMC can be processed into complex shapes to meet diverse design needs.

However, SMC is heavy and has average performance in high-frequency environments. Moreover, its molding depends on molds. The mold cost is high and is more suitable for mass production.

SMC is often used to make circuit breaker housings and motor insulation frames to provide insulation and structural support for power equipment.

FR4 is an epoxy glass cloth laminate with good electrical insulation performance and high cost performance. It is a commonly used material in the PCB industry. It is easy to process and can be cut, drilled to meet the design requirements of different circuit boards.

However, in high temperature environments, FR4 may have delamination problems, affecting material performance. And it is easy to absorb moisture, and the electrical insulation performance will be significantly reduced after moisture absorption.

Therefore, FR4 is mostly used to make circuit boards and low-voltage insulation components. It is suitable for occasions with low requirements for temperature resistance and moisture resistance.

Mica is divided into natural mica and synthetic mica, which can withstand high temperatures up to 1000℃ and has excellent arc resistance. Mica is flexible and can be processed into thin sheets or strips, suitable for a variety of scenarios. In high-frequency environments, mica has low loss and can ensure stable signal transmission.

However, mica has insufficient mechanical strength and usually needs to be reinforced with other materials. And its price is relatively high, which limits large-scale application.

Mica is often used for insulation of electric heating pipes and motor windings to provide insulation protection for equipment in high-temperature and high-frequency environments.

Ceramic materials such as alumina and aluminum nitride play an important role in the field of power electronics. They have stable chemical properties and hardly react with other substances. Among them, aluminum nitride ceramics have outstanding thermal conductivity and fast heat dissipation. At the same time, ceramics have good insulation properties and are suitable for high-voltage and high-temperature environments.

However, ceramics are brittle, easy to break, and difficult to process. This leads to high processing costs and high prices for ceramics.

At present, ceramics are mainly used in power module substrates, high-voltage insulators and other occasions with high performance requirements to ensure stable operation of power equipment in extreme environments.

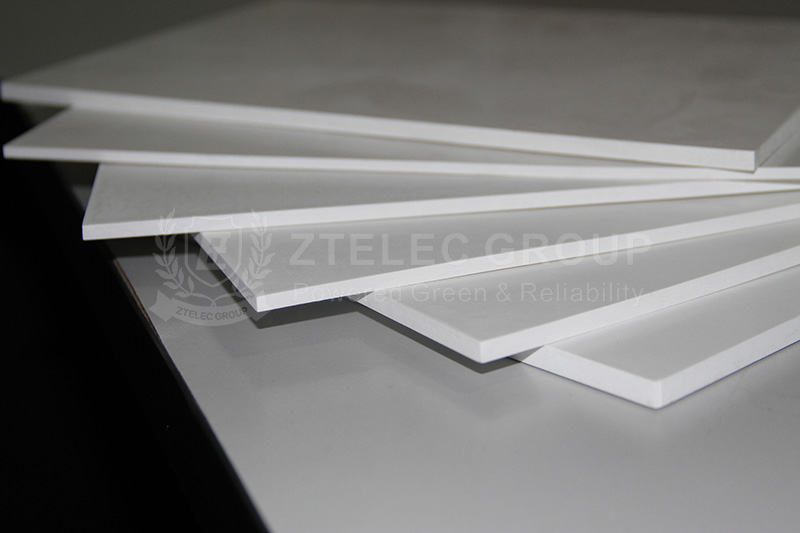

Electrical board, also called bakelite board or phenolic board, is low-cost and easy to process. Its insulation performance can meet the needs of general electrical equipment.

However, the electrical board has poor temperature resistance and is easy to deform at high temperatures. At the same time, it is easy to absorb moisture, deform after absorbing moisture, and is prone to aging after long-term use.

Therefore, electrical boards are often used to make low-voltage electrical components such as low-voltage terminal blocks and relay bases that do not require high performance.

By comparing these five power electronic insulation materials, their characteristics can be more clearly understood. In practical applications, appropriate materials can be selected according to specific needs to ensure efficient and safe operation of power equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……